Three-phase separation and waste water purification standard treatment device of kitchen waste including 'waste oil' and solid waste and kitchen waste water

A technology for kitchen waste and kitchen waste water, which is applied in the direction of flotation water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problem of large volume and floor area, poor oil-water separation effect, etc. problem, to achieve the effect that is conducive to cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

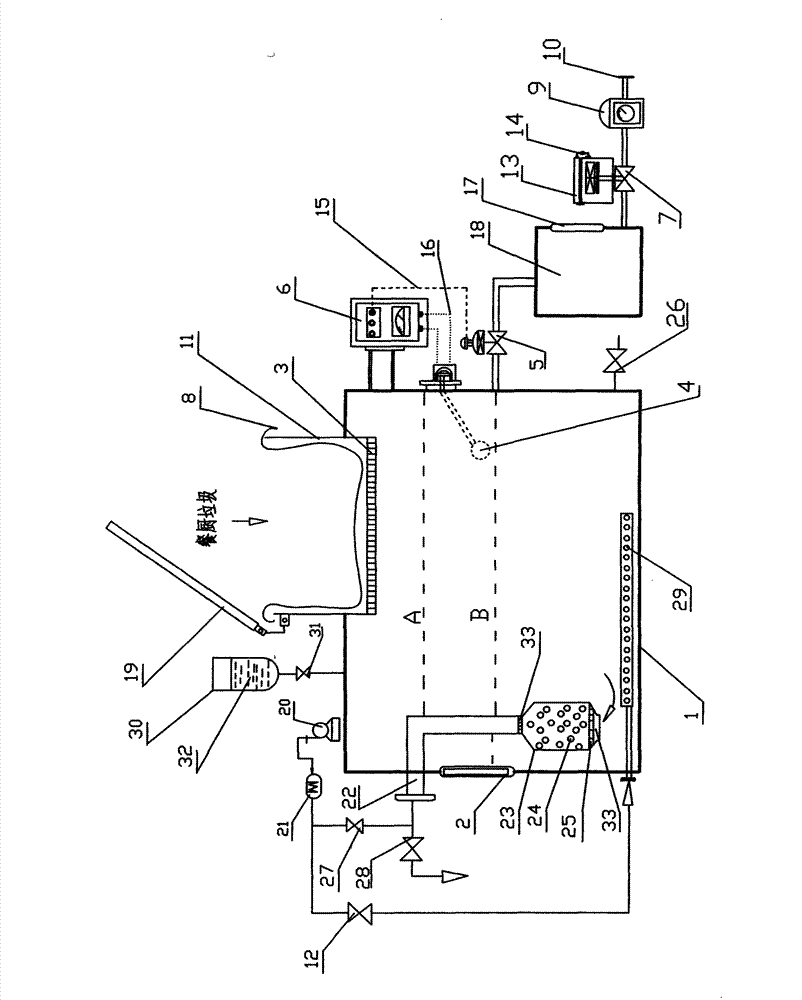

[0041] A rectangular shell (1) made of stainless steel is 1.67 meters long, 1.2 meters high, and 1 meter wide, or a volume of 2 cubic meters; the top of the shell (1) is equipped with a cylinder with a diameter of 50 cm and a height of 35 cm The solid-liquid separation chamber (11) of shaped stainless steel, the plate thickness of the filter hole partition (3) on the bottom surface of the solid-liquid separation chamber (11) is 1 centimeter, and the aperture is 6 millimeters, and the top of the orifice plate (3) is an inner sleeve A polyethylene plastic bag (4) with a hole (3mm); the top configuration of the housing (1) has a diameter of 35 centimeters, a cylinder height of 50 centimeters of stainless steel dosing tank (30), a dosing tank (30 ) containing polyaluminum chloride solution, the middle and upper part of the side of the housing (1) is equipped with a commercially available SZL-3(B) oil-water interface sensor (4) and a matching controller (6); the valve (5) The inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com