Engine controller, controller of engine and hydraulic pump, and engine, hydraulic pump and controller of generator motor

A technology of generator motor and control device, which is applied in the direction of engine control, machine/engine, electrical control, etc., can solve the problems of pump efficiency, fuel consumption and noise deterioration, etc.

Inactive Publication Date: 2008-10-29

KOMATSU LTD

View PDF2 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, there is a problem that the engine 2 does not operate in the low rotation range unless it is set by the fuel dial, and the pump efficiency, fuel consumption, and noise deteriorate.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 1 Embodiment

no. 2 Embodiment

no. 3 Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

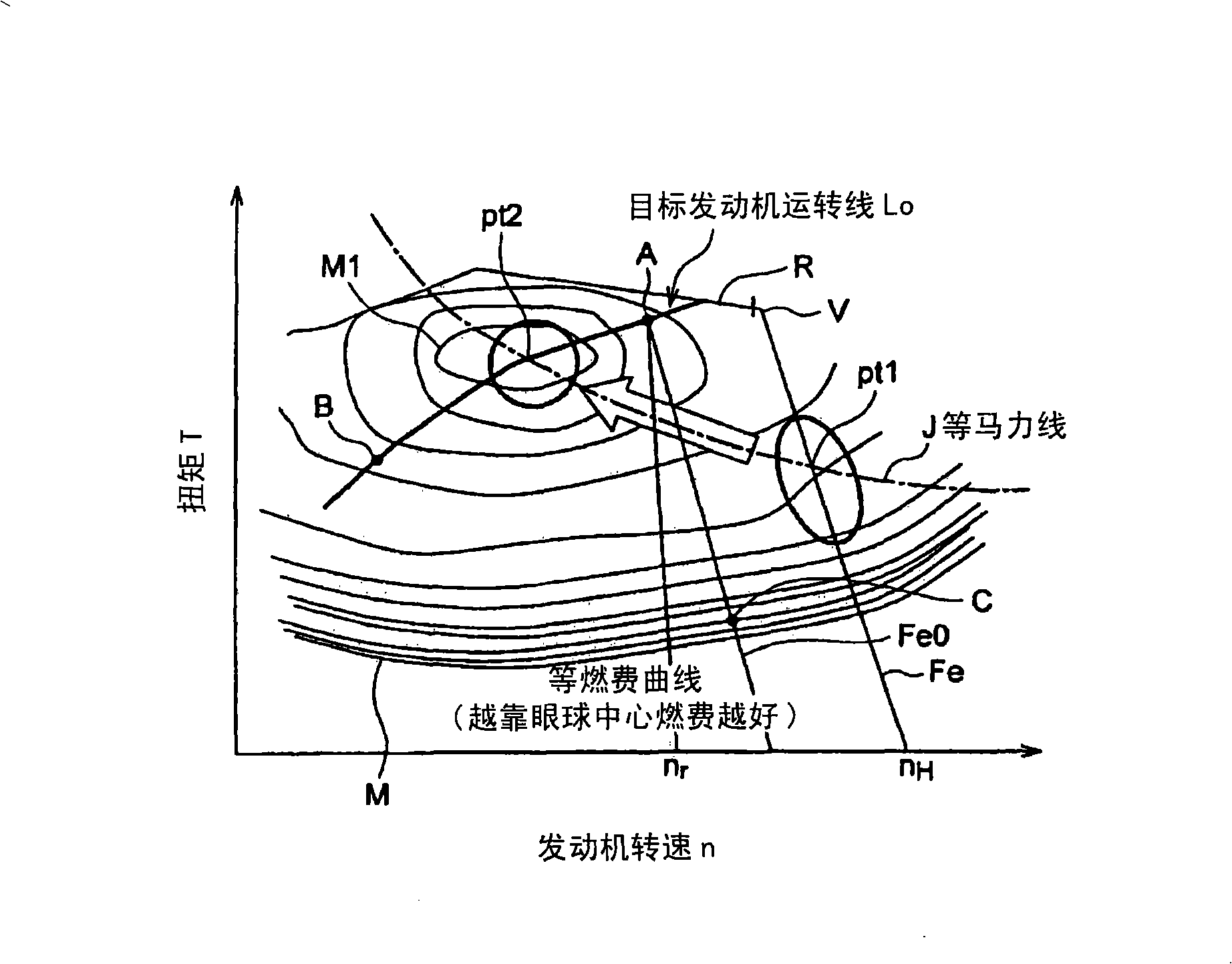

A working machine is operated as intended by an operator with good response and with enhanced engine efficiency, pump efficiency, and the like. A first engine target speed of rotation ncom1 conforming to a current pump target delivery flow rate Qsum is set, and when a decision is made that the current pump target delivery flow rate Qsum is higher than a predetermined flow rate (e.g. 10 (L / min)), a decision is made that operating means (41-44) are switched from nonoperating state to operating state, and a speed of rotation nM (e.g. 1400 rpm) higher than the engine idle speed of rotation nL is set as a second engine target speed of rotation ncom2. If the second engine target speed of rotation ncom2 is higher than the first engine target speed of rotation ncom1, engine speed of rotation is controlled to attain the second engine target speed of rotation ncom2.

Description

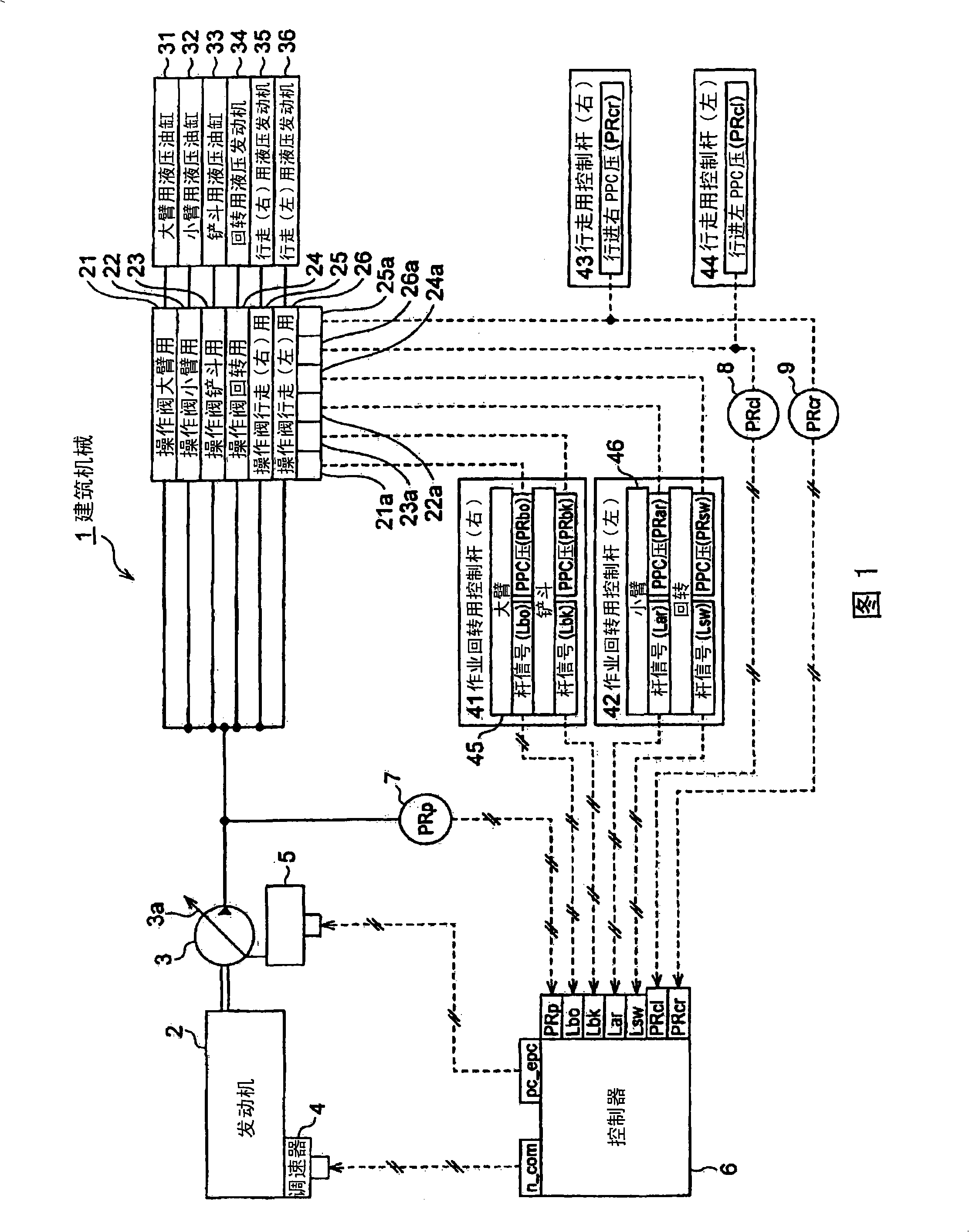

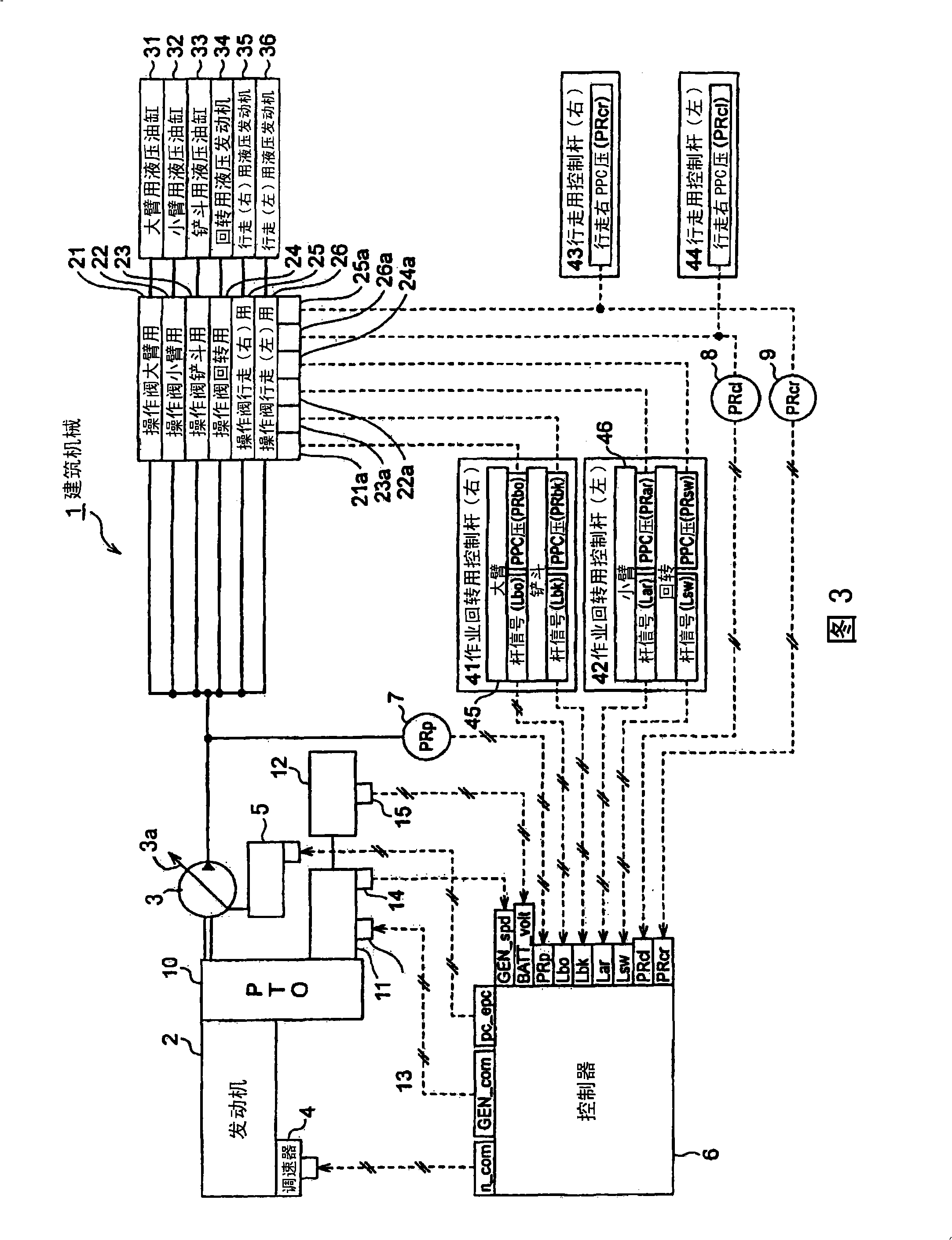

Engine control devices, engine and hydraulic pump control devices, and engine, hydraulic pump and generator motor control devices technical field The present invention relates to a control device for an engine, a control device for an engine and a hydraulic pump, and a control device for an engine, a hydraulic pump, and a generator motor, and particularly to a control device used when the hydraulic pump is driven by the engine. Background technique Diesel engines are installed in construction machines such as hydraulic excavators, bulldozers, dump trucks, and wheel loaders. The configuration of a conventional construction machine 1 is schematically described with reference to FIG. 1 . As shown in FIG. 1 , a diesel engine 2 is used as a driving source to drive a hydraulic pump 3 . The hydraulic pump 3 is a variable capacity type hydraulic pump, and the capacity q (cc / rev) is changed by changing the inclination angle of the swash plate 3a or the like. The pressure oil disc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F02D29/04F02D29/00E02F9/20F02D45/00

Inventor 森永淳河口正井上宏昭

Owner KOMATSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com