Balance valve

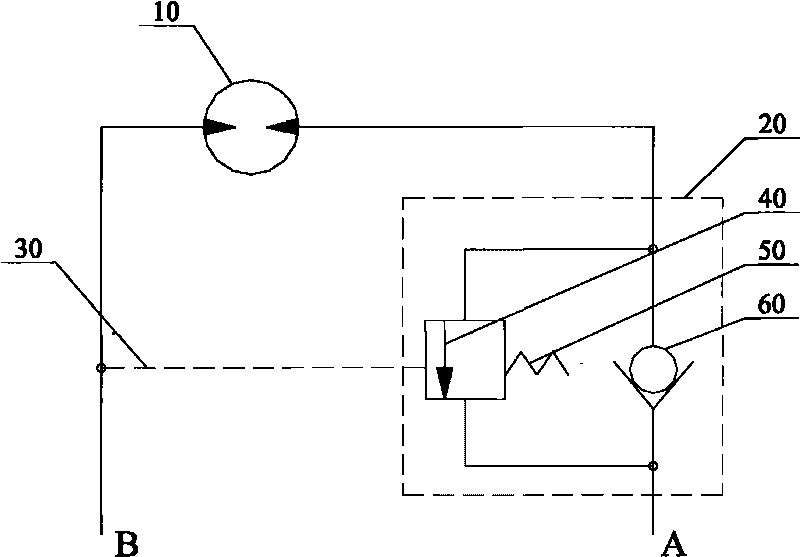

A technology of balancing valve and valve body, applied in the field of balancing valve, can solve problems such as affecting the safety performance of cranes, poor crane fretting, controlling pressure fluctuations, etc., and achieve the effects of avoiding hidden dangers of operation safety, smooth movement and eliminating jitter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

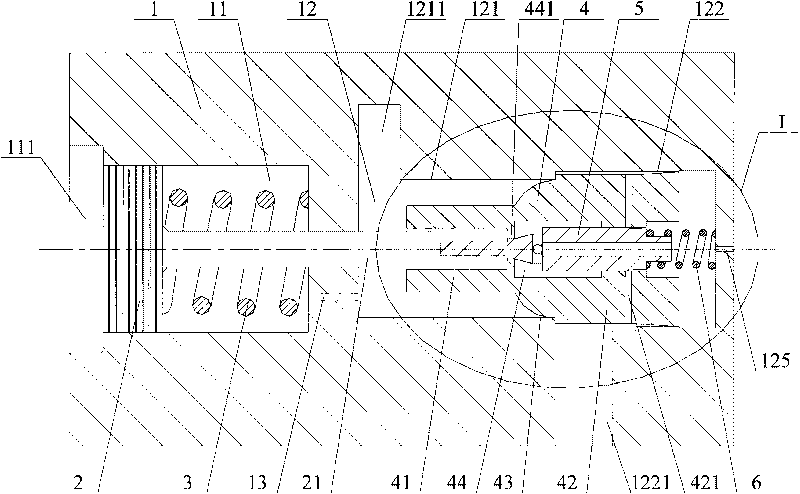

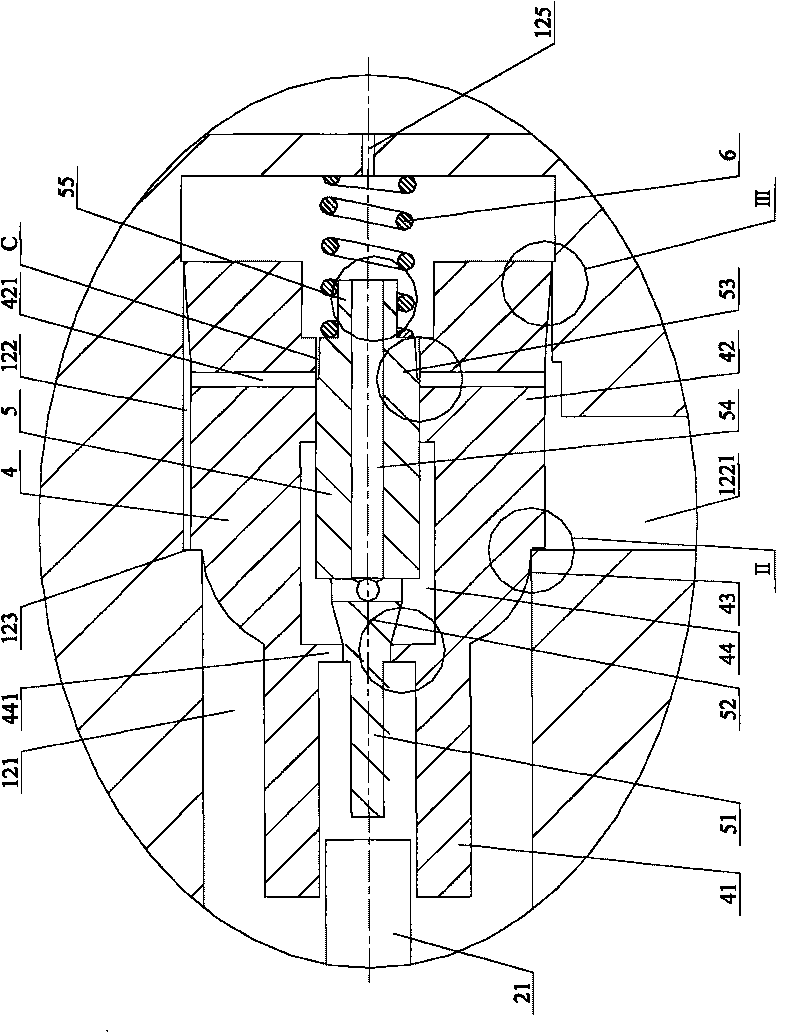

[0031] The core design of the present invention is to improve the structure and positional relationship between the main valve core and the control valve core. The damping structure is designed to improve the movement stability of the main spool.

[0032] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0033] see figure 2 , which is a schematic structural view of the balance valve provided by the present invention when it is in a non-conducting state.

[0034] Such as figure 2 As shown, the balance valve of the present invention is mainly composed of valve body 1, control piston 2, first spring 3, main spool 4, control spool 5, second spring 6 and other main components. In this paper, the structure and positional relationship of the above-mentioned main components will be described in detail. The realization of the cooperation relationship between the components with sealing requirements can be realized by those skil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com