Self-pulverization clinker indirect cooling equipment for fly ash limestone calcined alumina

A technology of calcined alumina and cooling equipment, which is applied in lighting and heating equipment, processing discharged materials, furnaces, etc., can solve the problems that clinker cooling cannot be realized, and achieve good material pulverization effect, long residence time, and moving parts small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

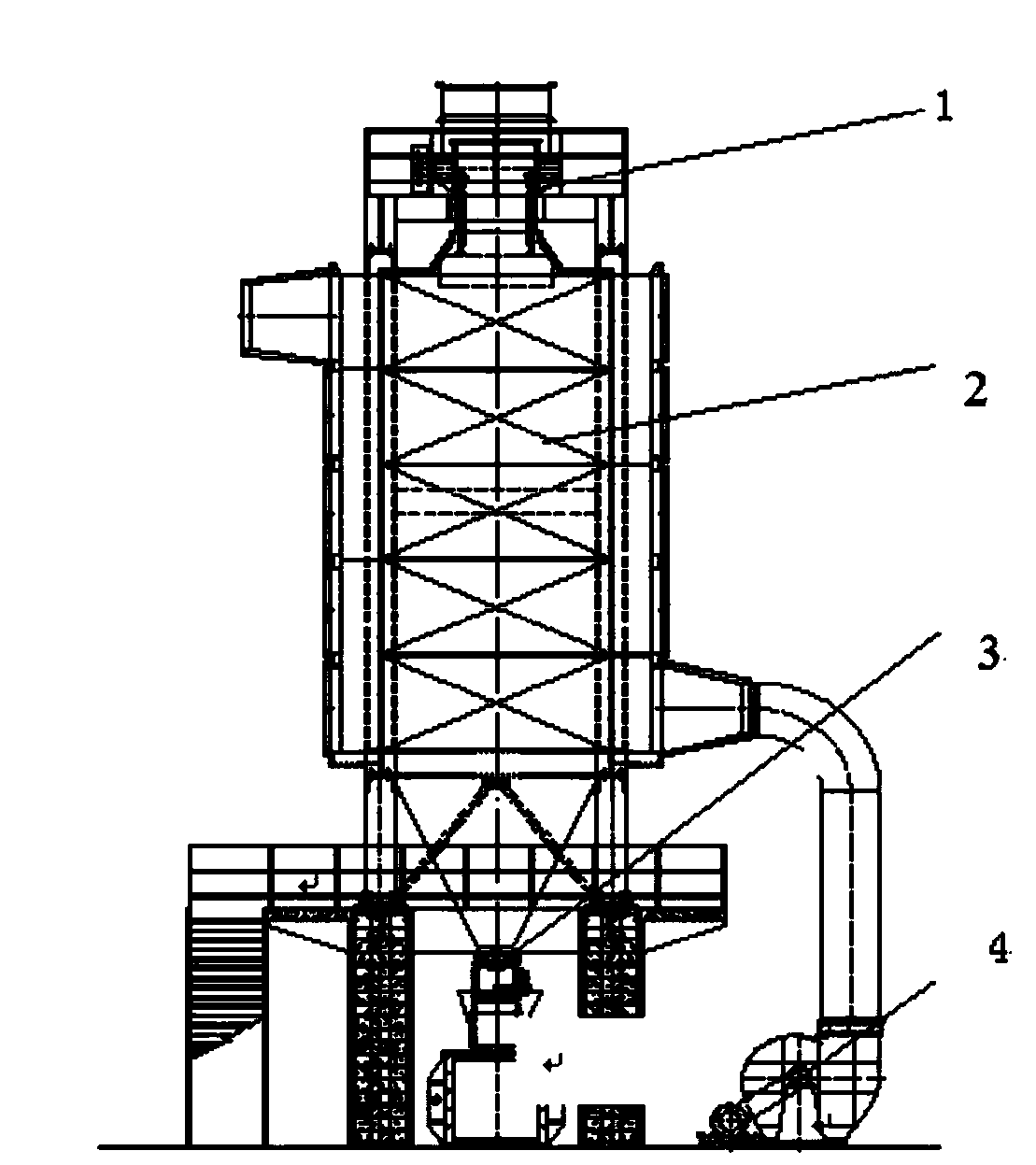

[0026] In this embodiment, calcined alumina self-powdered clinker is used for indirect cooling, the feed rate is 80t / h, and the feed temperature is 450°C. Six cooling modules are arranged in parallel in the vertical direction, and the blower 4 is started. After the equipment is in normal operation , the feed port 1 starts feeding, the powder is cooled by 6 cooling modules, and the powder is sent out from the discharge port 3, and the sending temperature is less than 60°C.

Embodiment 2

[0028] In this embodiment, calcined alumina self-powdered clinker is used for indirect cooling. The feed rate of a single unit is 60t / h, and the feed temperature is 475°C. Seven cooling modules are arranged in parallel in the vertical direction, and the blower 4 is started. Wait until the equipment is normal. After running, feed port 1 starts to feed, the powder is cooled by 7 cooling modules, and the powder is sent out from discharge port 3, and the sending temperature is less than 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com