Carbon-based catalyst desulfurization and denitrification system and method

A carbon-based catalyst, desulfurization and denitrification technology, applied in the field of environmental engineering, can solve the problems of inability to achieve low-concentration emission of pollutants, difficulty in adjusting carbon-based catalyst materials, material wear, etc., to reduce loss, reduce material wear, and reduce CO2. produced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

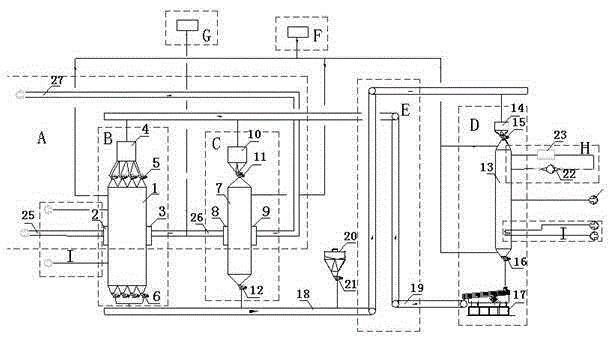

[0043] Below in conjunction with accompanying drawing, the present invention will be further described:

[0044] Such as figure 1 As shown, the carbon-based catalyst desulfurization and denitrification system of the present invention includes a flue gas system (A), a desulfurization adsorption system (B), a denitrification adsorption system (C), a carbon-based catalyst regeneration system (D), and a carbon-based catalyst delivery system. Machine system (E), nitrogen system (F), ammonia gasification dilution system (G), air heating system (H), cooling water system (I), all systems are connected by pipelines. Among them, the desulfurization adsorption tower (2) and the denitrification adsorption tower (7) are arranged in parallel, the flue gas is arranged in series, and the carbon-based catalyst materials are arranged in parallel.

[0045] Flue gas system (A) includes raw flue gas (boiler flue gas) input pipe (25), mixed gas pipe (26), clean flue gas discharge pipe (27), desul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com