Semiconductor device structure and forming method thereof

A device structure and semiconductor technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as difficulty, insignificant improvement in speed, and difficulty in realization, and achieve the effect of improving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

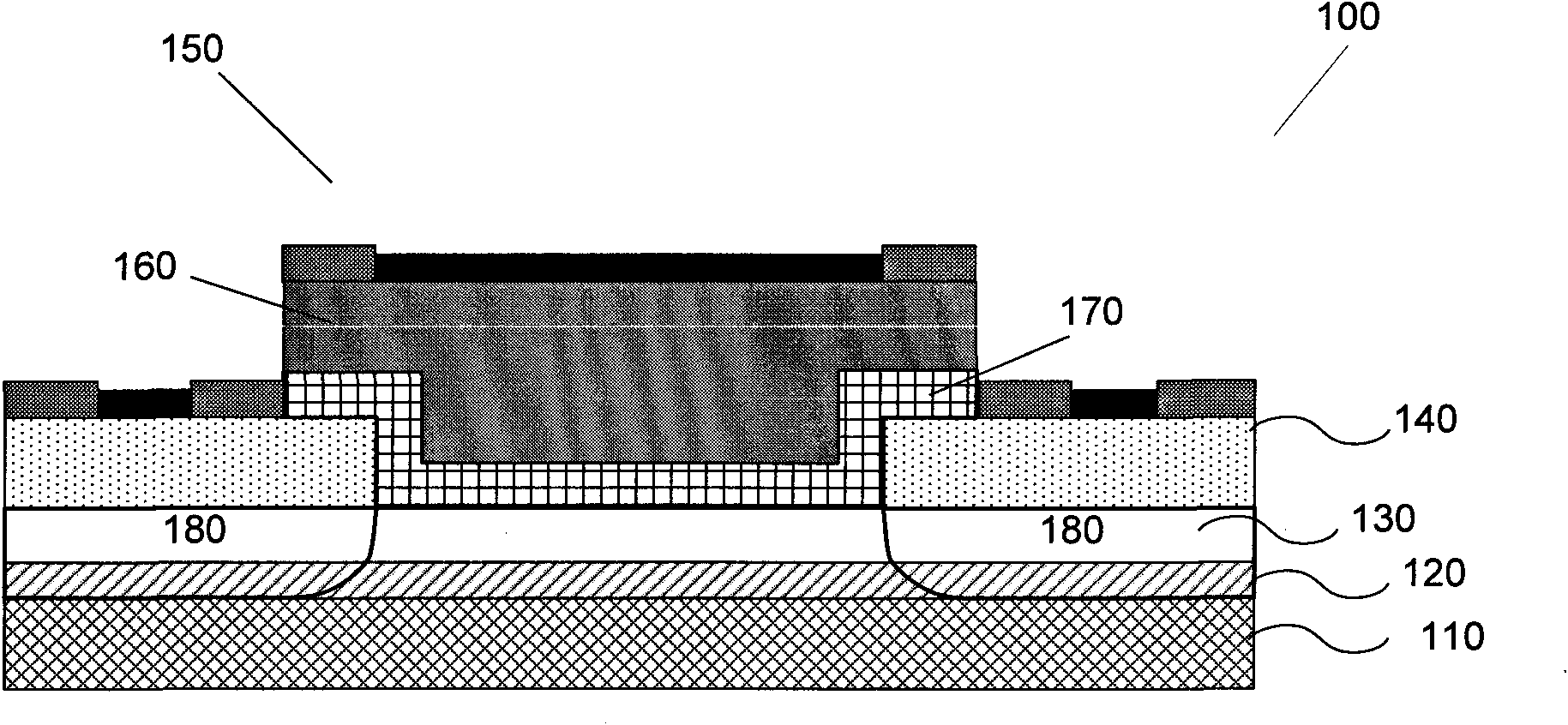

[0022] Such as figure 1 Shown is a structural diagram of a semiconductor device according to Embodiment 1 of the present invention. The semiconductor device structure 100 includes an insulating or semi-insulating substrate layer 110, an insulating substrate such as SiO 2 , silicon nitride, etc., and the semi-insulating substrate may include SiC or GaAs with a wide band gap. A silicon carbide layer (Silicon carbide layer) 120 formed on the insulating or semi-insulating substrate layer 110, and a carbon-based material layer 130 formed on the silicon-carbon layer 120, in one embodiment of the present invention, the carbon-based material Layer 130 may include a single layer or multiple layers of graphene. The semiconductor device structure 100 also includes a gate stack 150 formed on the carbon-based material layer 130, a source electrode and a drain electrode 180 formed in the carbon-based material layer 130, and a gate stack formed on the source electrode and the drain electro...

Embodiment 2

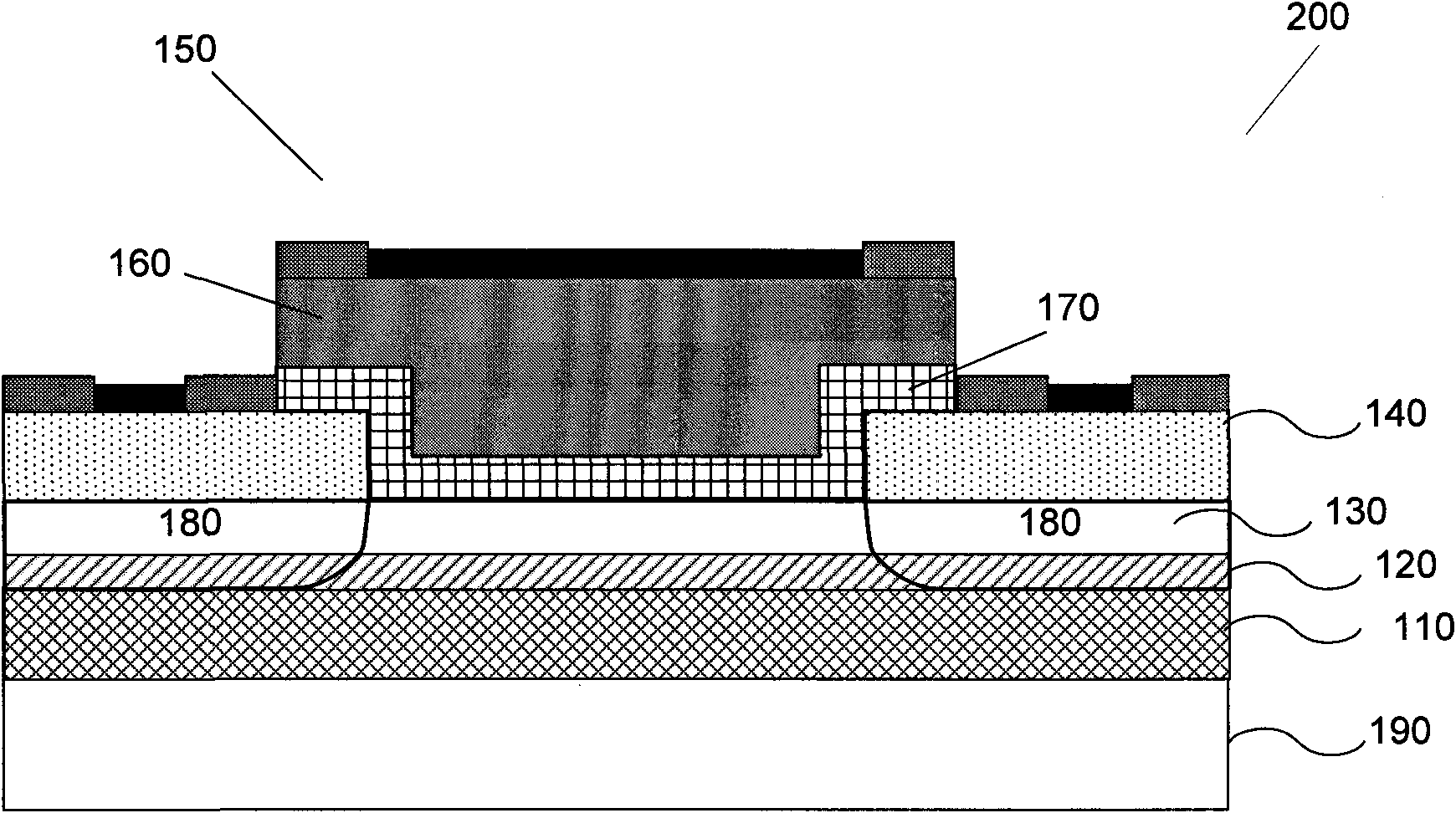

[0025] The present invention can also be formed on Si substrates, such as figure 2 Shown is a structural diagram of a semiconductor device according to Embodiment 2 of the present invention. This structure is similar to that of the first embodiment, except that the semiconductor device 200 further includes a Si substrate 190 in this embodiment. In one embodiment of the present invention, the Si substrate 190 may be an N-type Si substrate. It should be noted that, in this embodiment, the insulating substrate or semi-insulating substrate layer 110 of Embodiment 1 may not be required, for example, a silicon carbon layer may be directly grown on the Si substrate 190, and the silicon carbon layer A part of Si is fused with metal Ni to form the carbon-based material layer 130 and the metal silicide layer 140 , and the other part serves as the insulating or semi-insulating substrate layer 110 .

[0026] In order to more clearly understand the above-mentioned semiconductor structur...

Embodiment 3

[0037] Such as Figure 10 Shown is a structural diagram of a semiconductor device according to Embodiment 3 of the present invention. The semiconductor device structure 300 includes a substrate 310, a gate stack 320 formed on the substrate 310, one or more layers of sidewalls 360 formed on both sides of the gate stack 320, a source and a gate formed in the substrate 310. The drain 330 , and the silicon carbon layer 340 and the carbon-based material layer 350 formed under the gate stack 320 and in the substrate 310 . Wherein, the carbon-based material layer 350 is formed by annealing the silicon carbon layer and the metal layer, part of the Si in the silicon carbon layer fuses with the metal to form a metal silicide, and the remaining silicon carbon layer is the silicon carbon layer 340 . In one embodiment of the present invention, the metal layer may include, but not limited to, Ni, Al, Ti, Mo, W, Co, Pt, Pd, Ta or combinations thereof. In another embodiment of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com