Automatic three-d storehouse frame construction

A frame structure, three-dimensional warehouse technology, applied in the field of automatic palletizing and conveying systems, can solve problems such as immature work, reduce energy consumption, improve batch processing capabilities, and have high safety effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

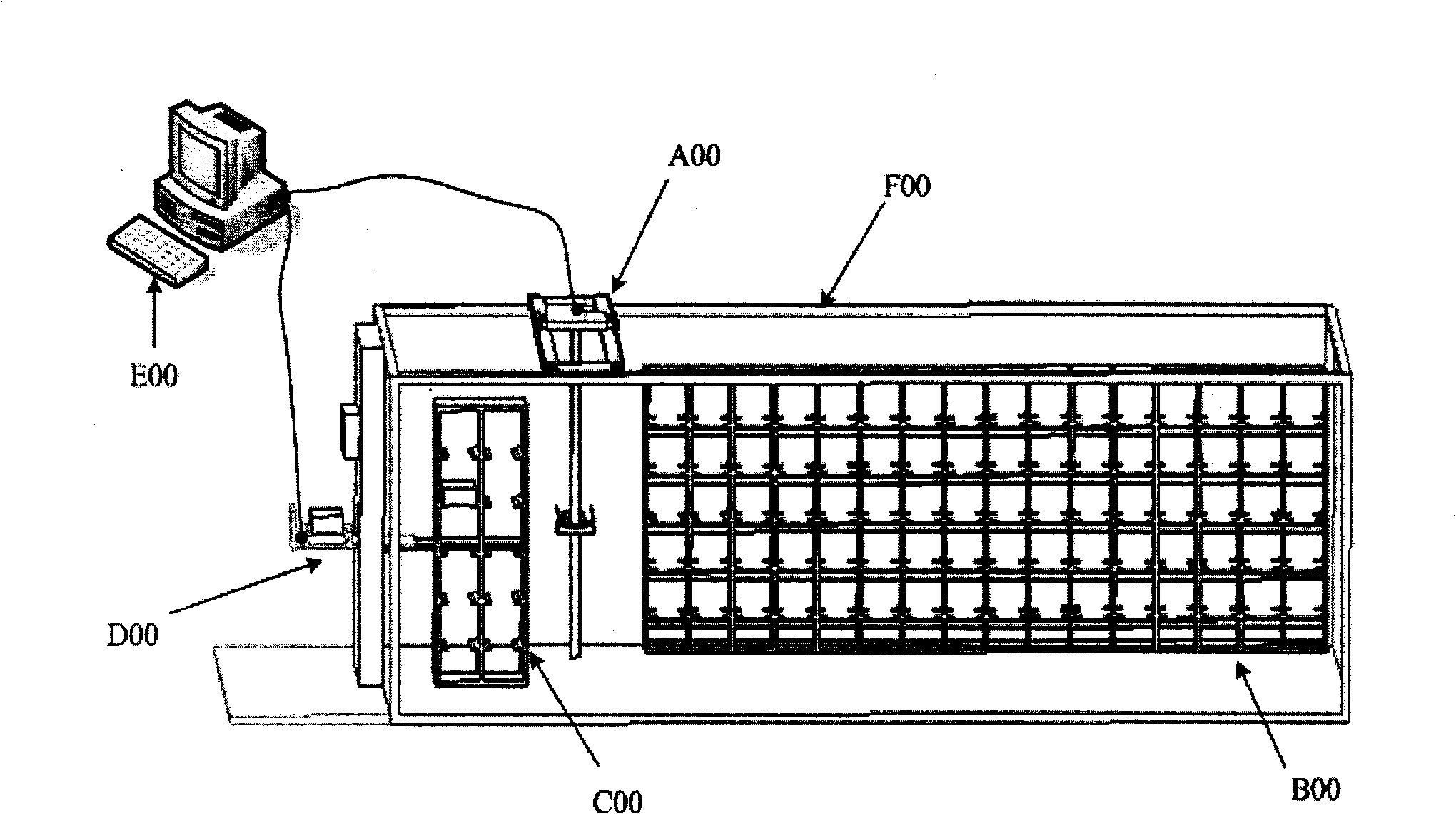

[0044] Implementation example of the present invention is aimed at the characteristics of quick-freezing cryogenic working environment, and overall structure of the present invention can be divided into six major parts: as figure 1 The three-dimensional schematic diagram of the overall structure of the deep-freezing and quick-freezing automated three-dimensional warehouse is as follows:

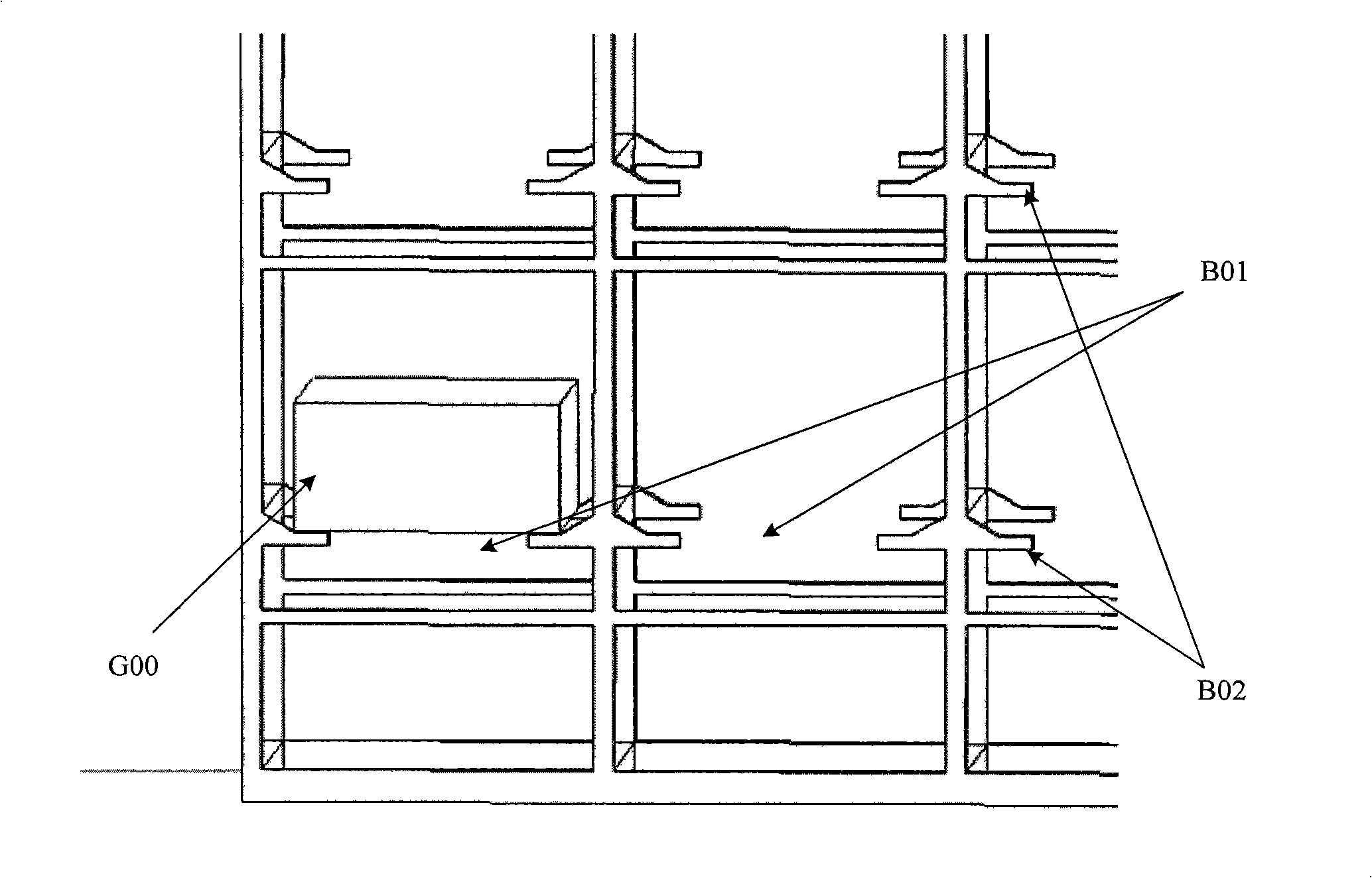

[0045] In the warehouse there are: stacker A00, roadway shelf B00, buffer shelf C00, guide rail F00;

[0046] At the entrance and exit window: automatic entry and exit mechanism D00;

[0047] Outside the warehouse there is: Computer E00.

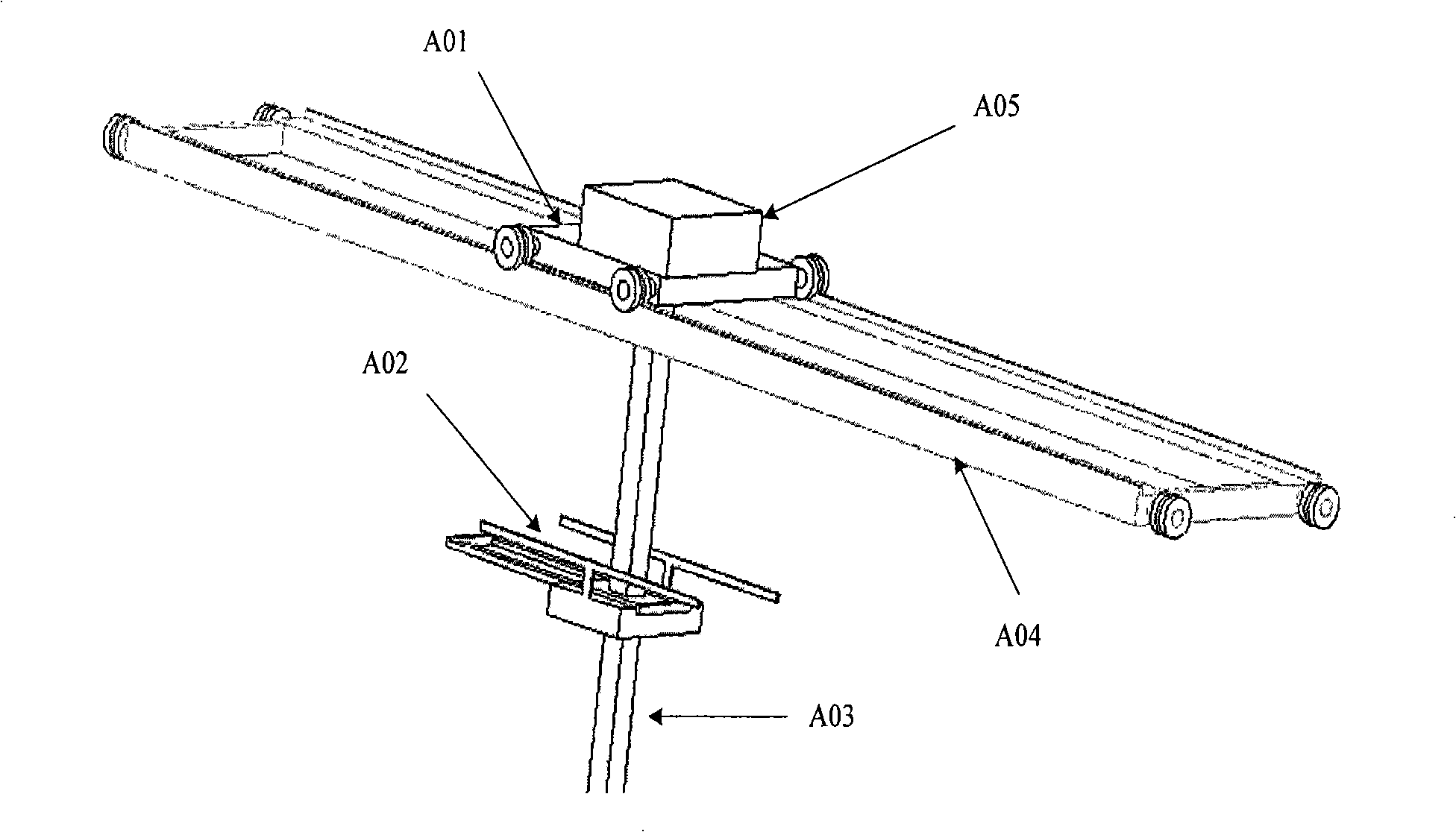

[0048] Stacker A00 adopts the mechanical structure of servo control system A05, tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com