Carburizing reinforced isothermal quenching workpiece and processing method thereof

A technique of austempering and carburizing, which is applied to carburized and strengthened workpieces and processing fields. It can solve the problems of poor toughness and fatigue strength, difficulty in controlling the deformation of workpieces, and the performance of workpieces that cannot meet the requirements of shaping, so as to achieve enhanced toughness and yield strength. Effect of improving service life and improving surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

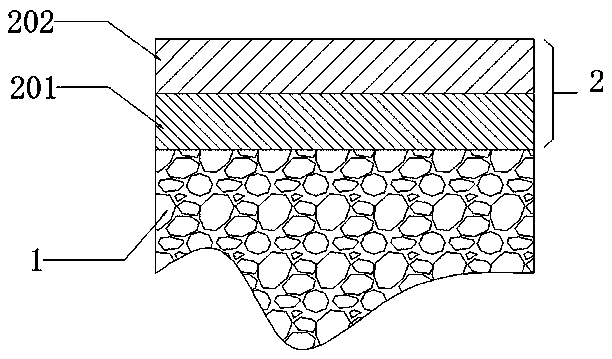

[0027] refer to figure 2 Shown, the austempering workpiece of carburizing strengthening of the present invention mainly comprises: matrix and carburized layer.

[0028] Wherein, the matrix contains ferrite, and as a preferred solution, the matrix also contains lath martensite.

[0029] The carburized layer specifically includes two sub-layers: the transition layer connected to the substrate, the surface layer connected to the transition layer on the surface, the surface layer is located on the outermost side as the surface structure of the workpiece, and the transition layer is between the substrate and the surface layer. between. The transition layer contains ferrite and the surface layer contains retained austenite.

[0030] As a preferred solution, the transition layer also contains bainite, and the bainite in this layer is lower b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com