Laser beam processing method

A laser processing method and laser processing technology, applied in the directions of laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of support body fracture, cutting support body pieces, etc., to improve yield, improve workability, increase Effects of laser power and movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

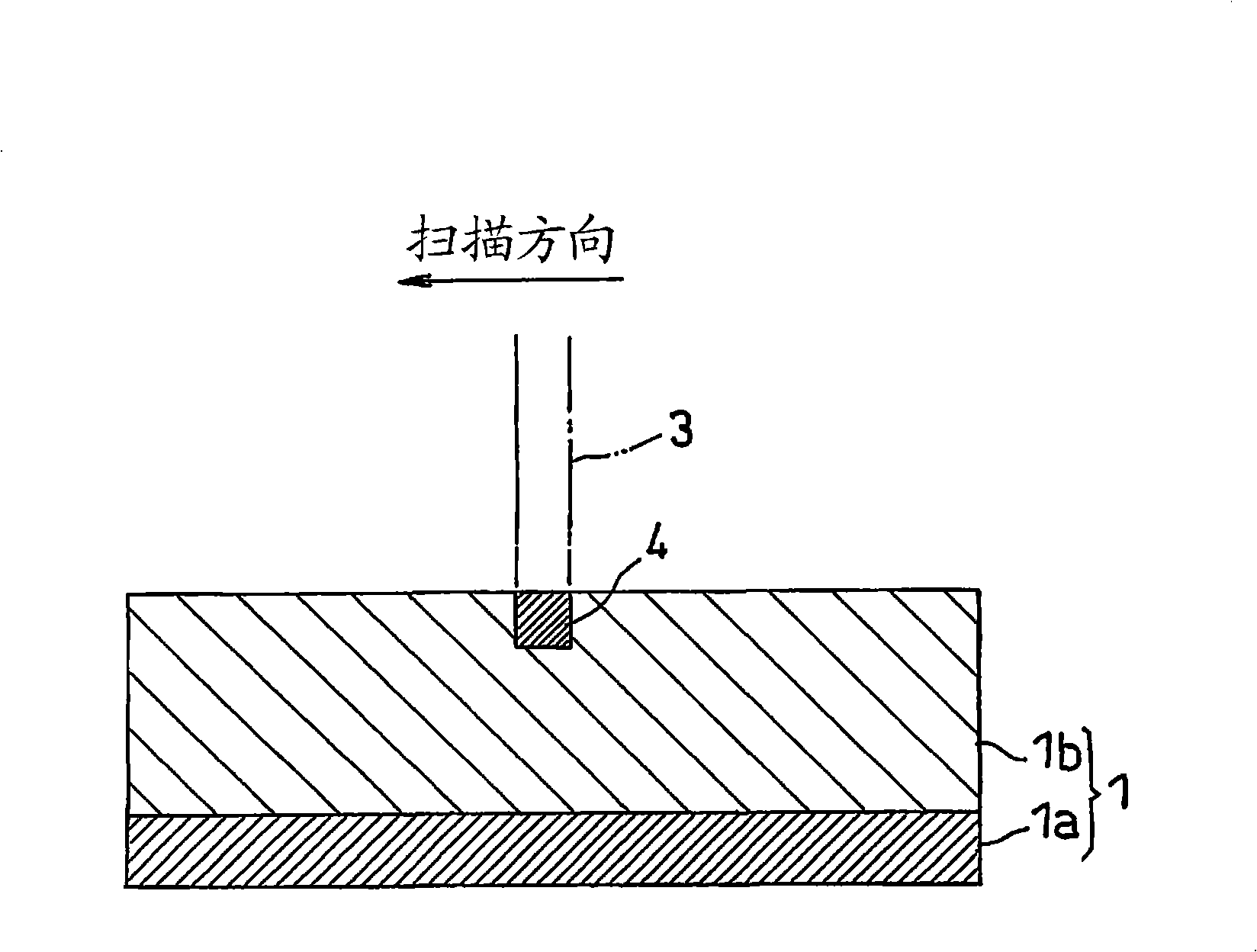

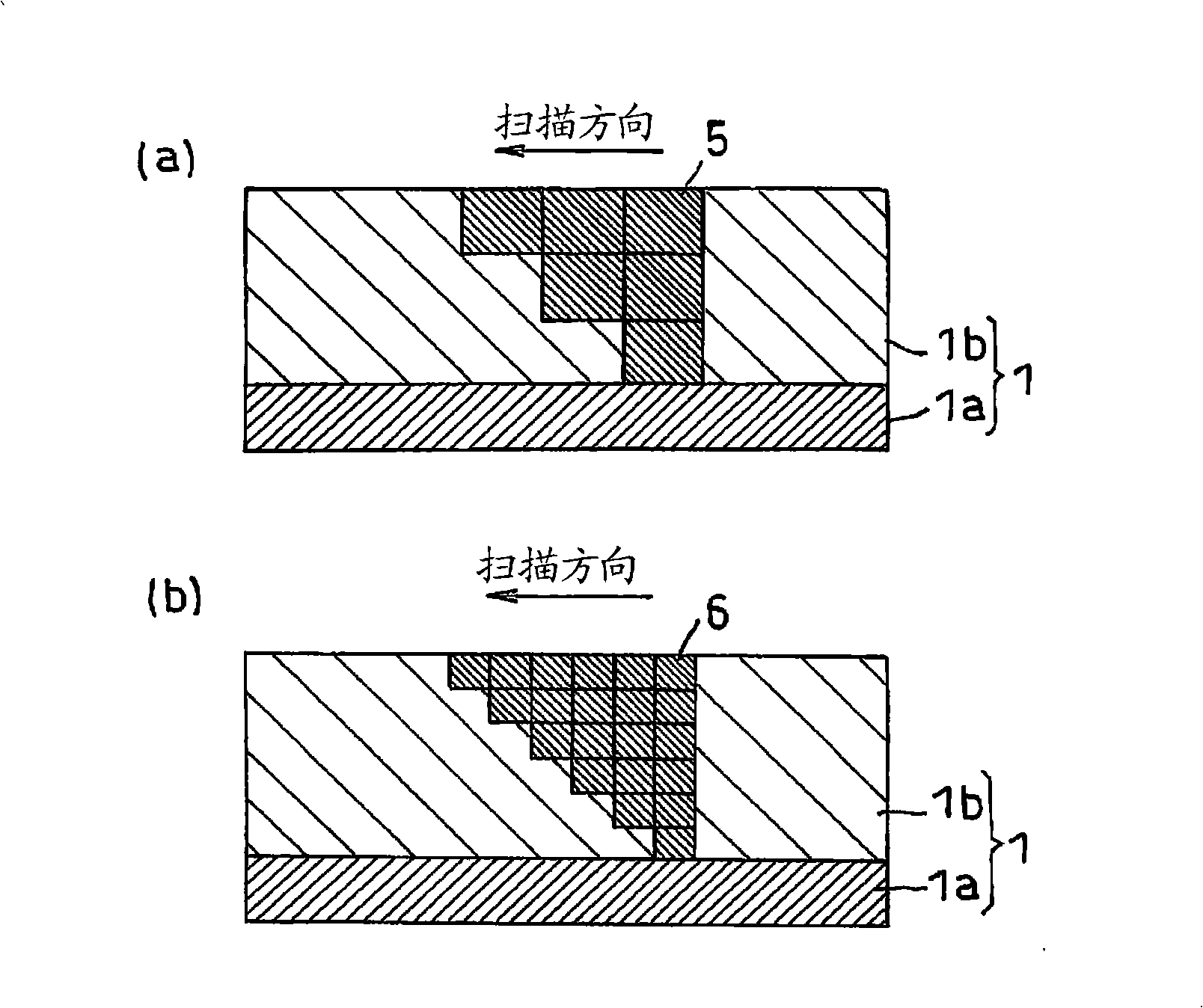

Method used

Image

Examples

Embodiment 1

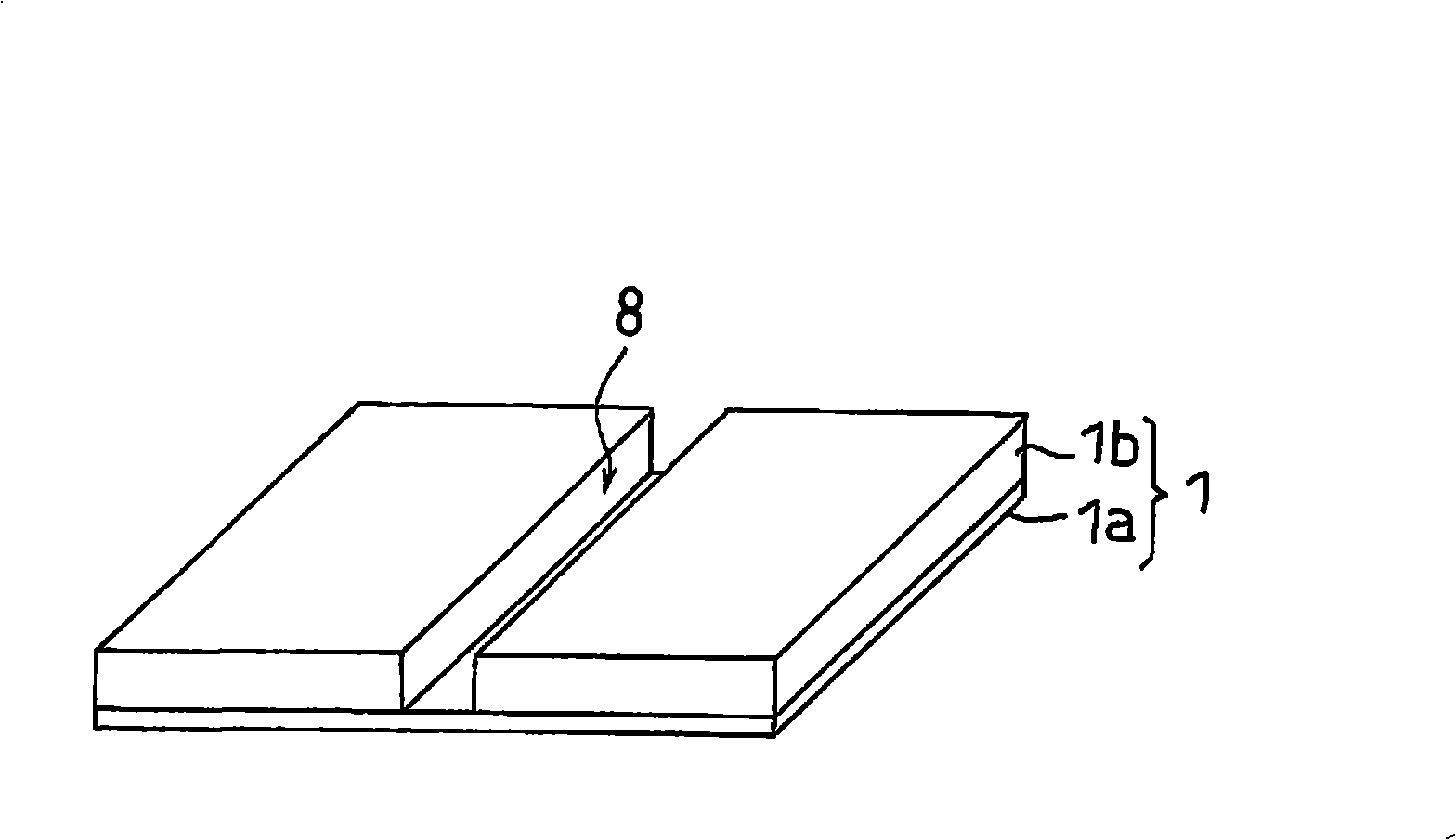

[0040] [processed object]

[0041] In this embodiment 1, as a processed object, such as Figure 5 In the polarizing plate with a spacer (total thickness: 270 μm) having the structure shown, the polarizing plate 9 was cut and processed without laser processing the spacer 10 (thickness: 38 μm) as a support.

[0042] [Laser irradiation device]

[0043] The laser irradiation apparatus used is as follows.

[0044] Laser light source: carbon dioxide laser

[0045] Laser wavelength: 10.6μm

[0046] Maximum output power: 250W

[0047] [Laser irradiation conditions]

[0048] Half-cut processing of the polarizing plate with a separator was performed under the following conditions.

[0049] Laser power: 42W

[0050] Spot diameter: φ120μm

[0051] Repetition frequency: 20kHz

[0052] Scanning speed: 400mm / s

[0053] Number of scans: 1 time

[0054] Energy input per unit length: 0.105J / mm

[0055] Under the above-mentioned processing conditions, the half-cut processing of the p...

Embodiment 2

[0062] In this embodiment 2, as the processed object, such as Figure 5 In the polarizing plate 11 with a spacer (total thickness: 270 μm) having the structure shown, the polarizing plate 9 was cut and processed without laser processing the spacer 10 (thickness: 38 μm) as a support.

[0063] As the laser irradiation device, the same device as in Example 1 was used, and the laser irradiation conditions were as shown in Table 2 below, and the number of scans was 2 times. In addition, similarly to Example 1, the laser power was changed intentionally, and the range of the laser power which can perform a half-cut process was confirmed. As a result, an increase of 21W or less is considered to be a range in which half-cutting can be performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com