Atomic force microscopy

a technology of atomic force and microscopy, which is applied in the direction of mechanical measurement arrangements, mechanical roughness/irregularity measurements, instruments, etc., can solve the problem of tiny deflection of cantilever beams, and achieve the effect of simplifying the arrangement, and reducing the cost of optical fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Atomic force microscopes are known in the art as described, for example, in U.S. Pat. No. 4,724,318 issued to G. Binnig and assigned to the same assignee or the present invention, which patent is incorporated herein by reference. While the Binnig patent describes a method of measuring the tip to surface distance by means of monitoring the tunneling current, the present invention measures the tip orientation by optical-beam-deflection, as will be described hereinafter. The present invention is most advantageous for operation in an inaccessible environment, such as in a vacuum or an ultrahigh vacuum, due to the provision of a remotely positionable position-sensitive detector.

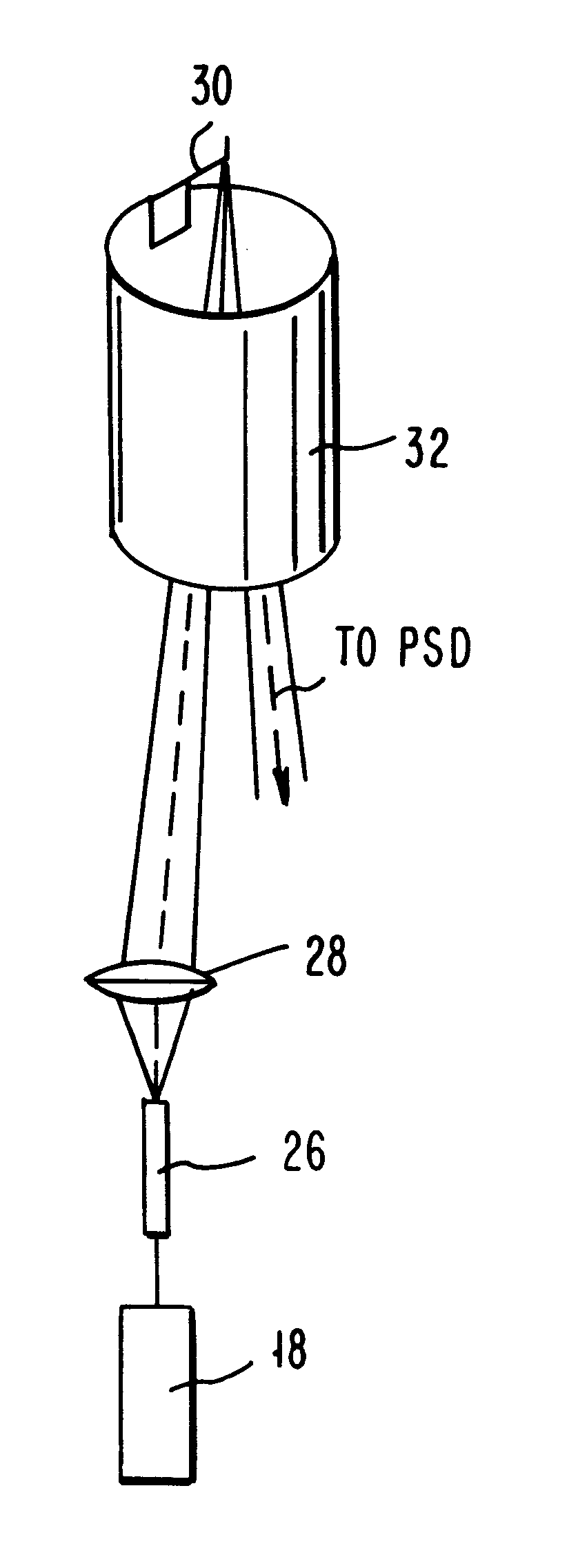

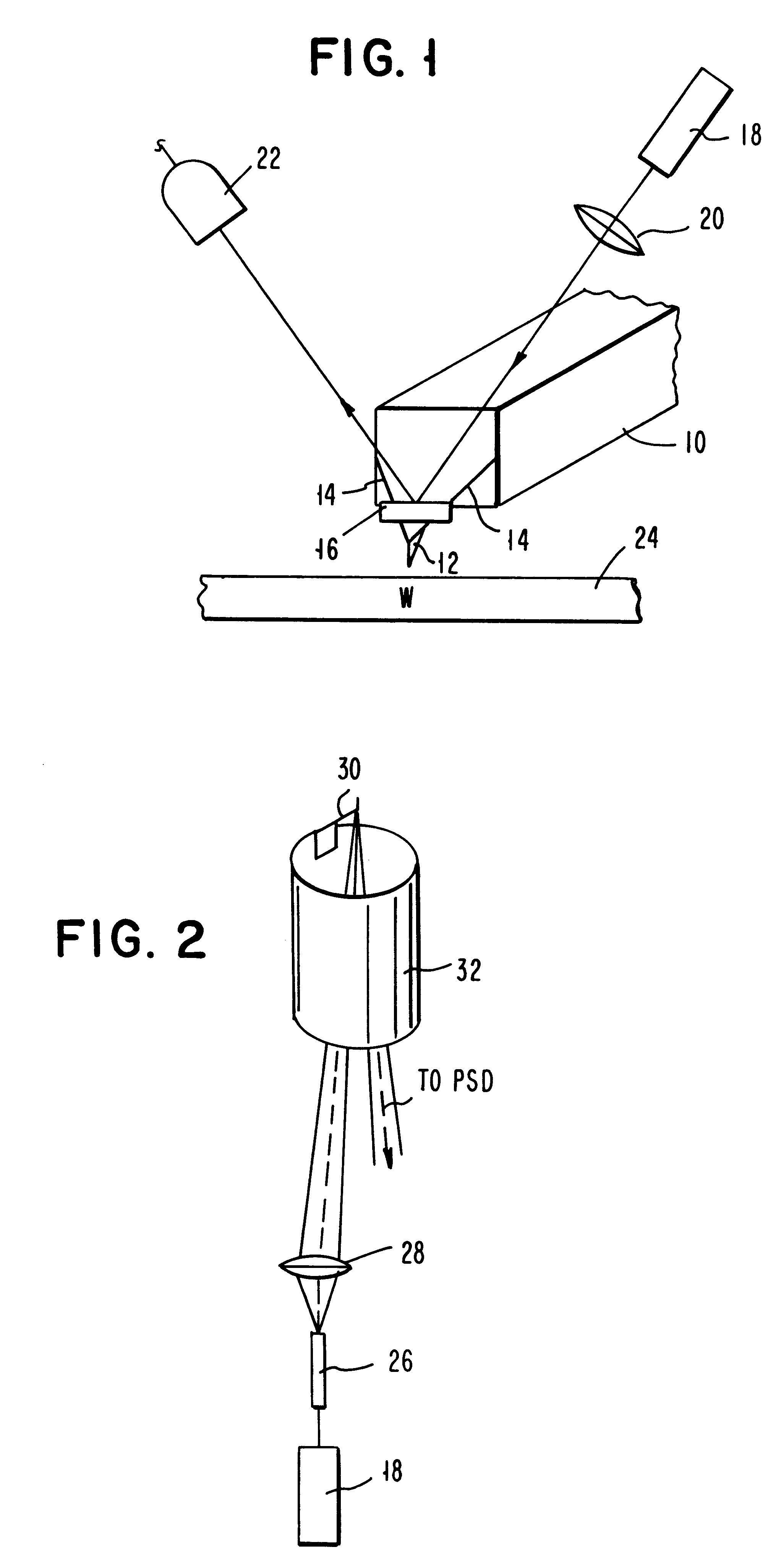

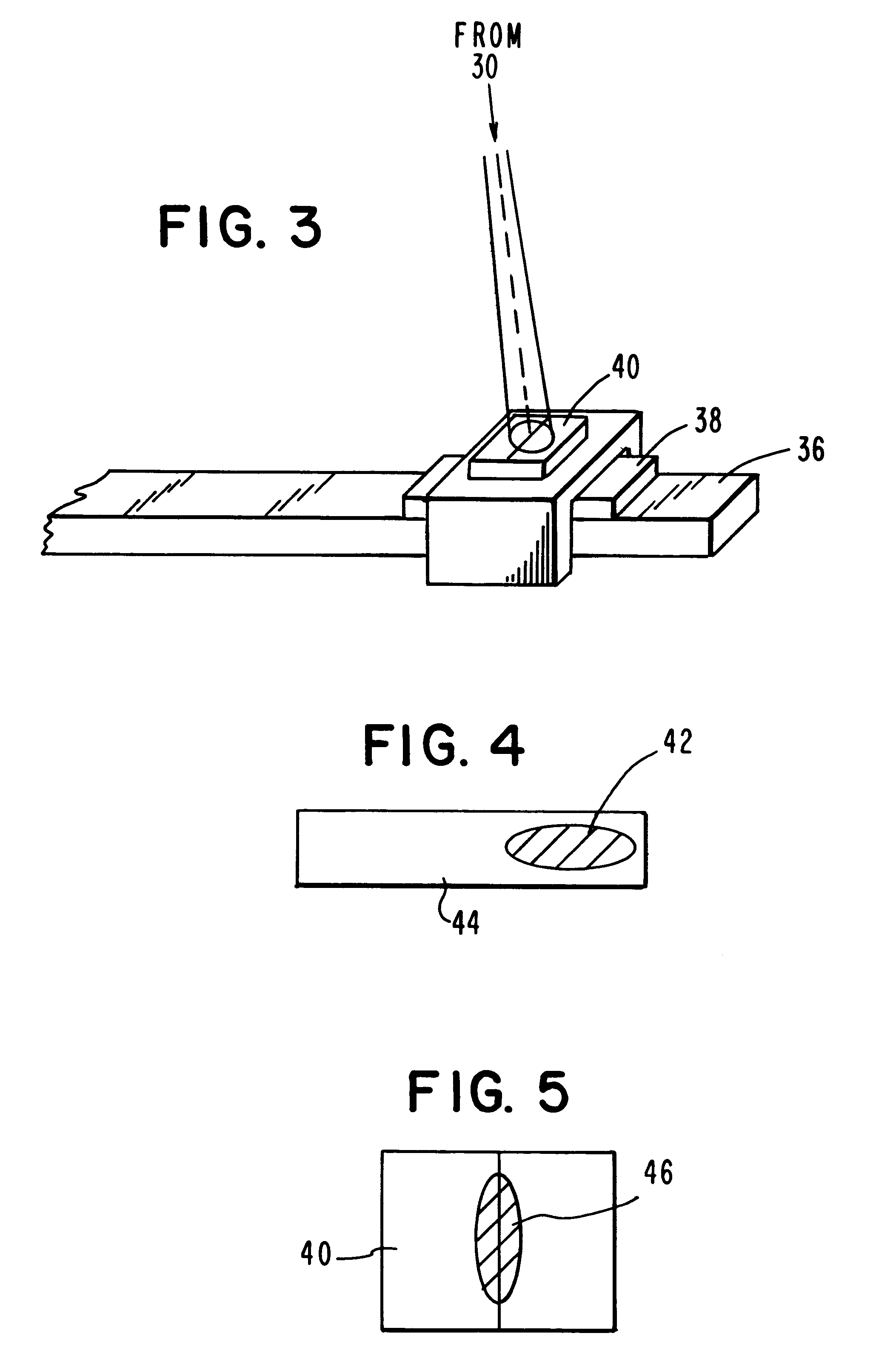

Referring now to the figures and to FIG. 1 in particular, there is shown a schematic representation of a cantilever beam deflection detection scheme. A stylus-cantilever system includes a cantilever beam 10 made of, e.g., silicon or silicon nitride, having a tip 12 of a length in the range between 1 and 10 microns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com