Phase grade self-coding-based optical three-dimensional measurement method

A self-encoding and phase technology, applied in the field of optical three-dimensional sensing, can solve problems such as rapid three-dimensional measurement of discontinuous object scenes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings, working principles and embodiments.

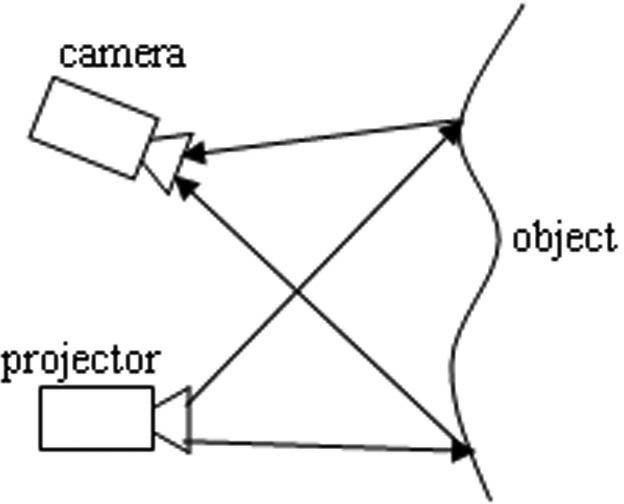

[0018] The optical path adopted by the phase-level self-encoder phase measurement method is similar to the traditional phase measurement profilometry measurement optical path. figure 1 It is a schematic diagram of a three-dimensional imaging system. The system is composed of a projector and a camera. The projector casts sinusoidal fringes, and the camera shoots the deformed fringes modulated by the surface topography of the object at another position. The phase distribution is calculated by analyzing the captured images, and then according to The relationship between phase and height can reconstruct the three-dimensional surface shape distribution of the object to be measured.

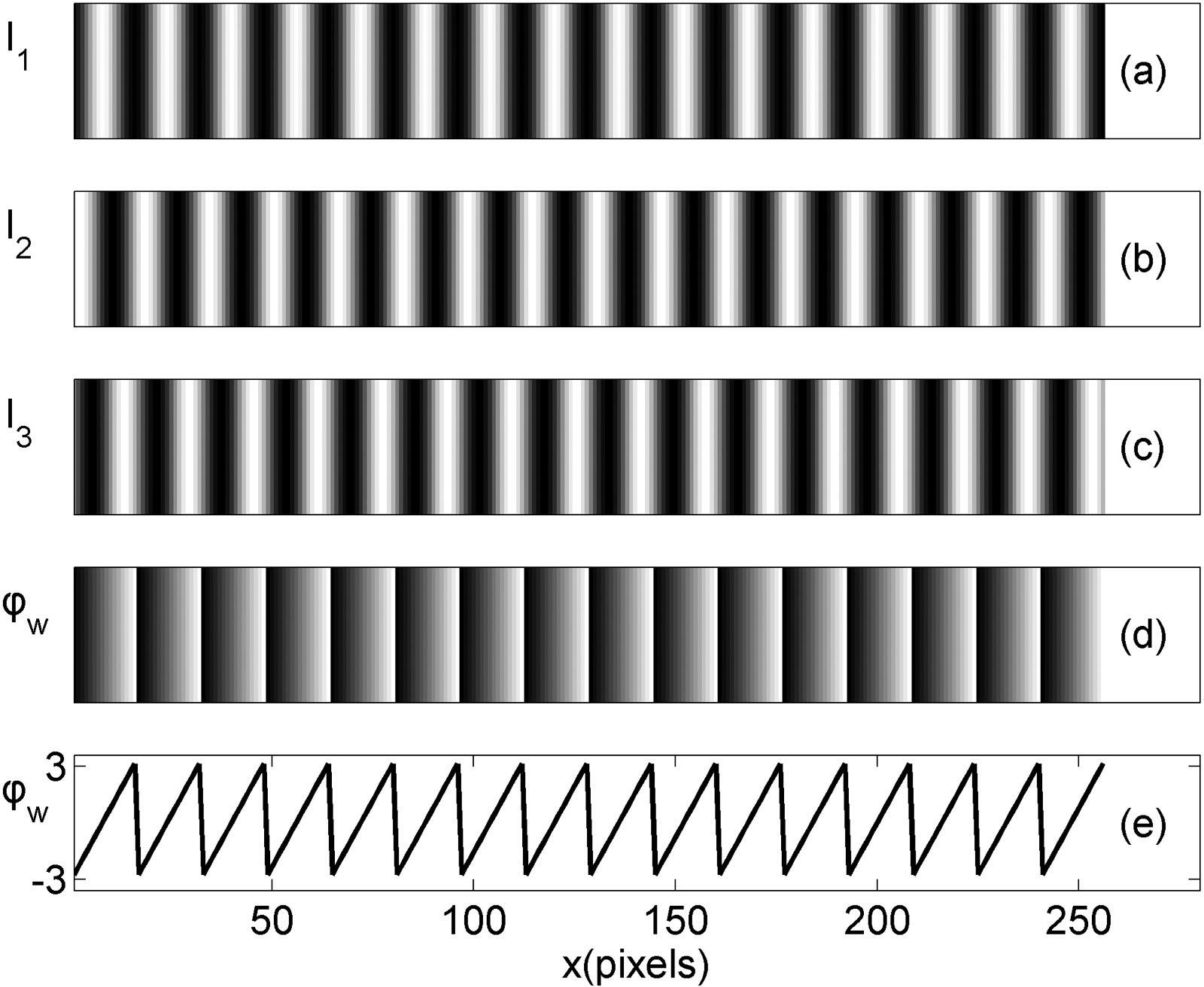

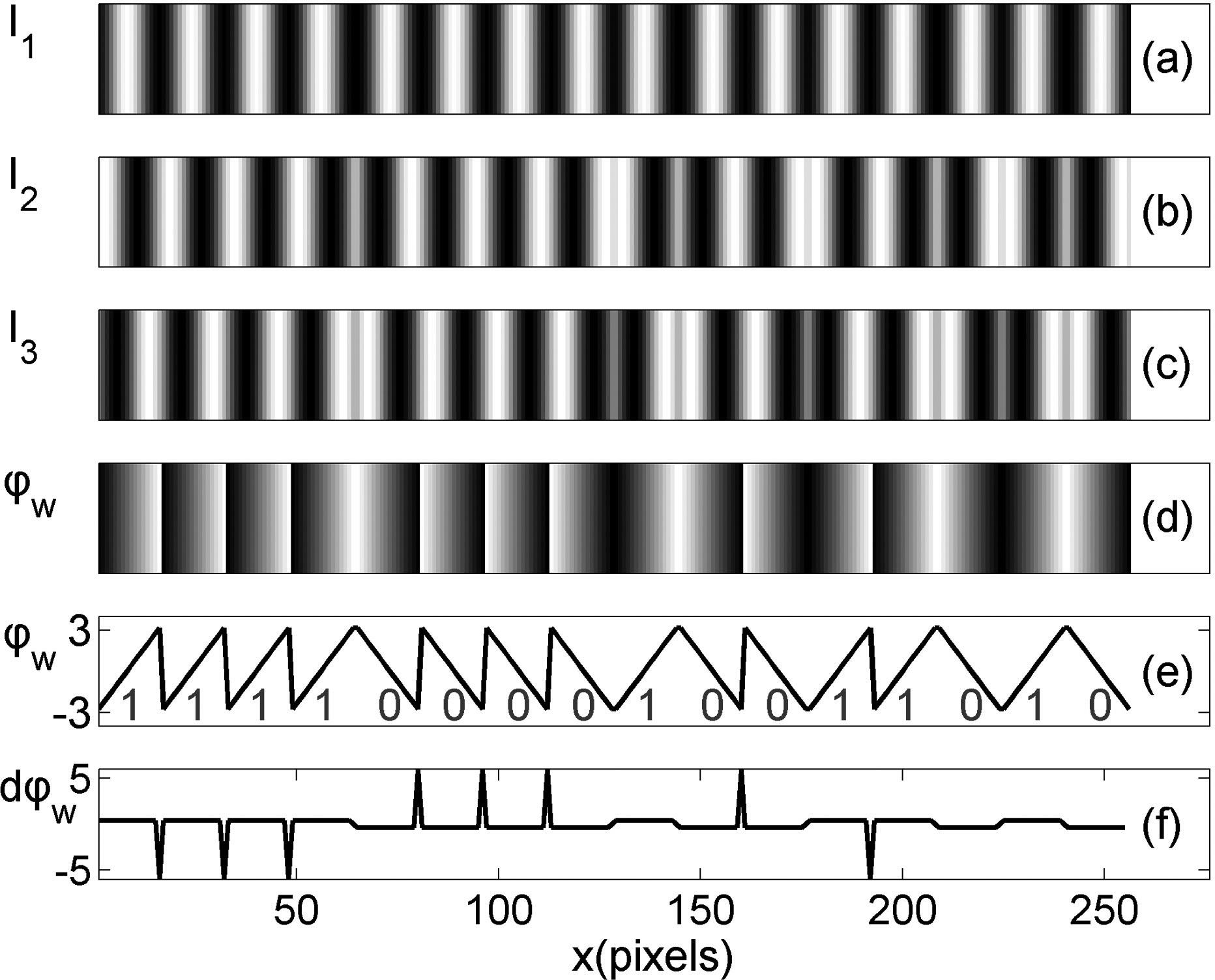

[0019] The intensity distribution of the phase-shifted sinusoidal fringe pattern of N frames to be projected generated by the computer can be expre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com