Patents

Literature

31 results about "Grade Code" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A coded value specifying the position on a scale of intensity or amount or quality.

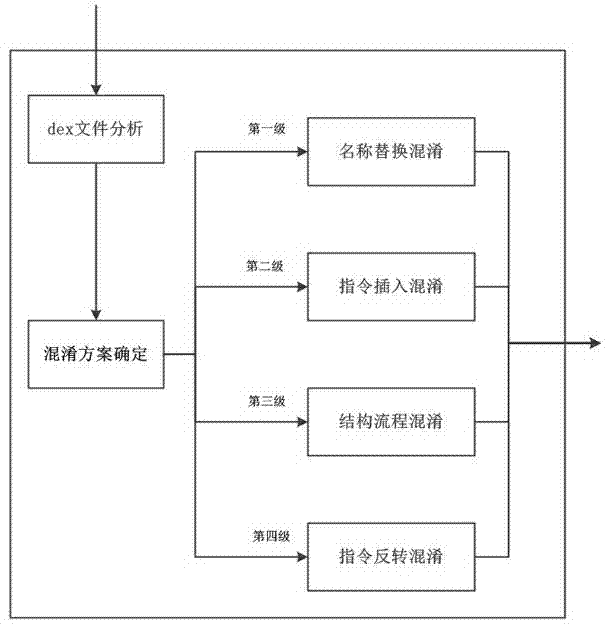

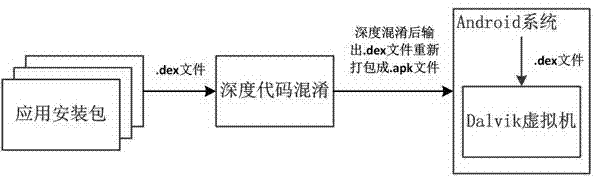

Deep code obfuscation method for Android system applications

ActiveCN103544414AImprove securityGuaranteed confidentialityProgram/content distribution protectionBase codeObfuscation

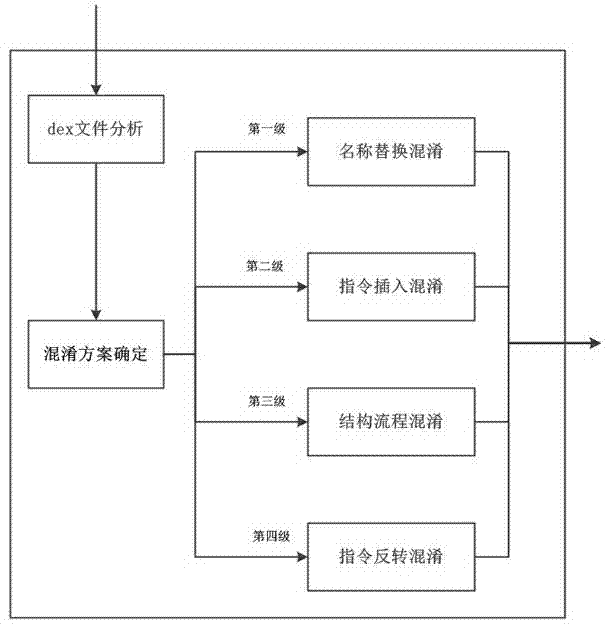

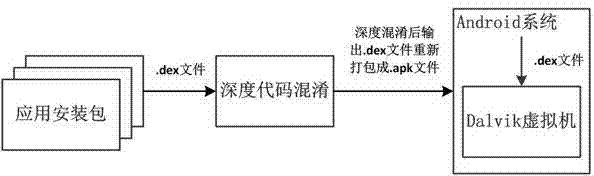

The invention discloses a deep code obfuscation method for Android system applications. The method uses graded code obfuscation. The graded code obfuscation includes first-grade name replacement obfuscation, second-grade command insertion obfuscation, third-grade structure process obfuscation, and fourth-grade command inversion obfuscation. For an application installation package developed and to be released, the method includes: extracting a DEX file, analyzing the file structure, a Dalvik instruction set and a program running process, determining an obfuscation scheme of corresponding grade or multiple combined grades to perform deep code obfuscation on the DEX file, generating a new DEX file, and re-packaging the file. The deep code obfuscation method according to the technical scheme has the advantages that the limitations of the traditional source-code-based code obfuscation scheme can be broken through, the DEX executable files are directly obfuscated in terms of element name, instruction and process structure, applications can be effectively protected from illegal cracking or inversion, safety of applications in the Android system is improved, and confidentiality of business software is guaranteed.

Owner:JIANGSU PAYEGIS INFORMATION SECURITY TECH CO LTD

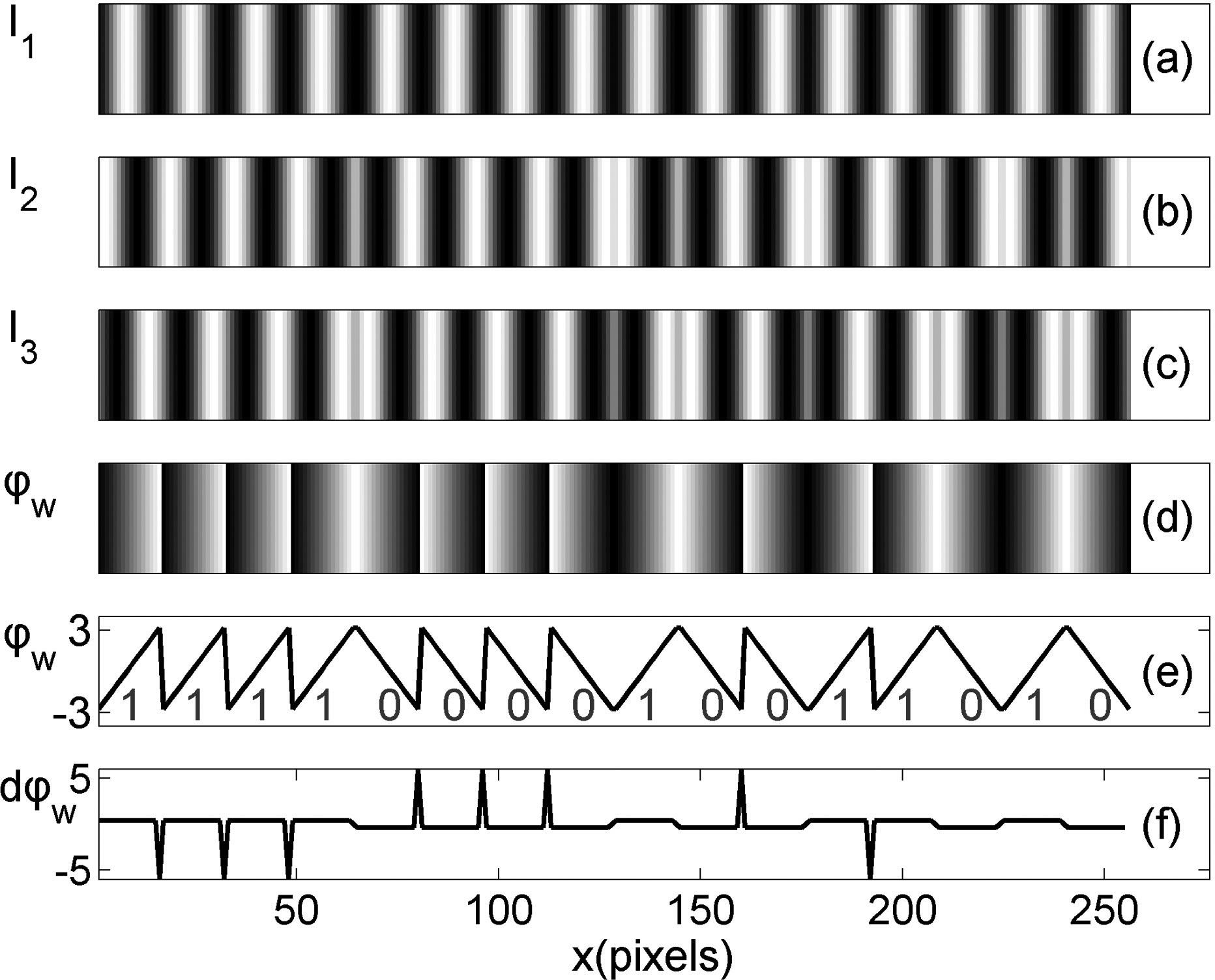

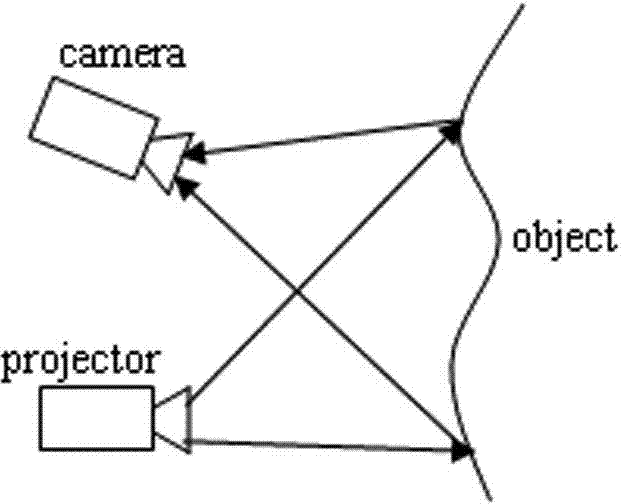

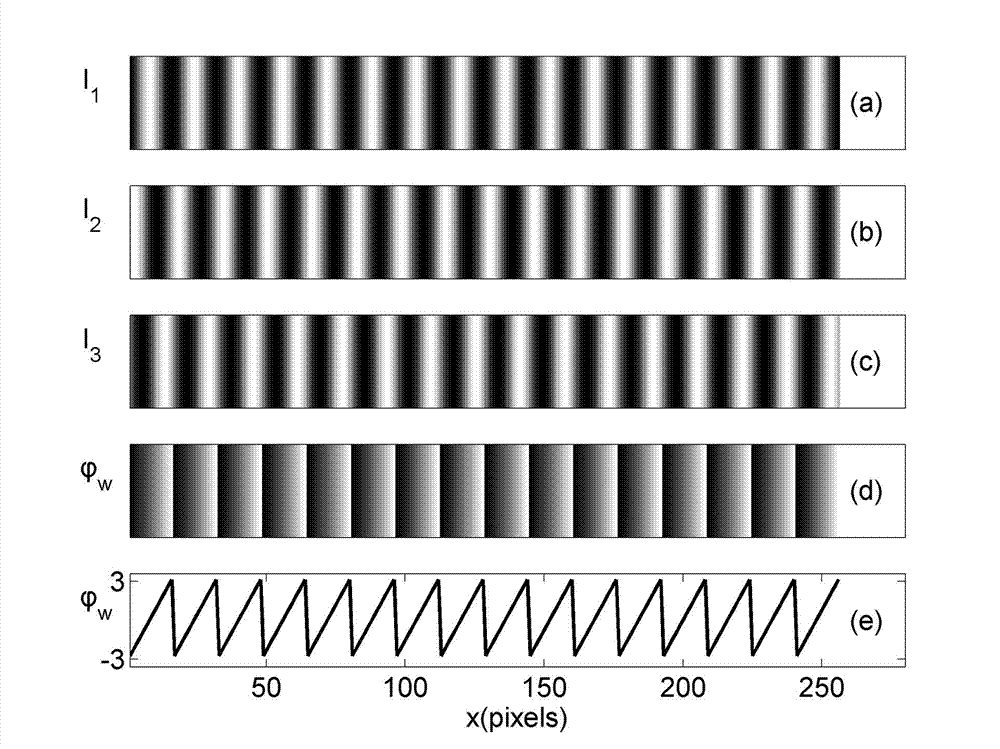

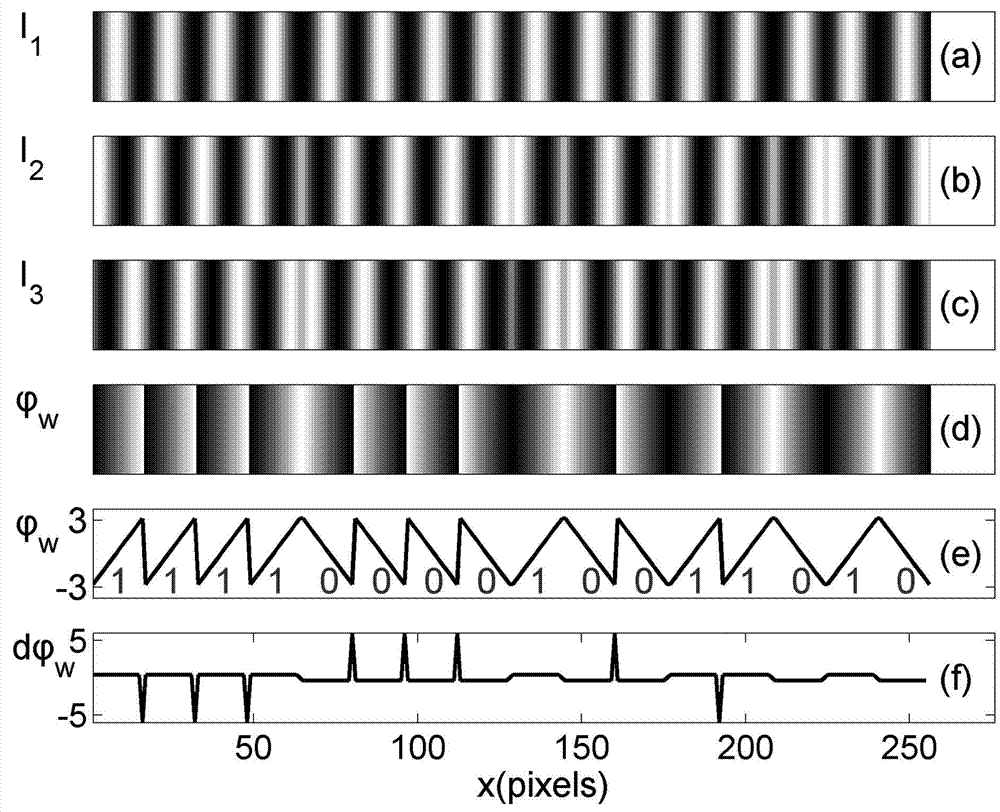

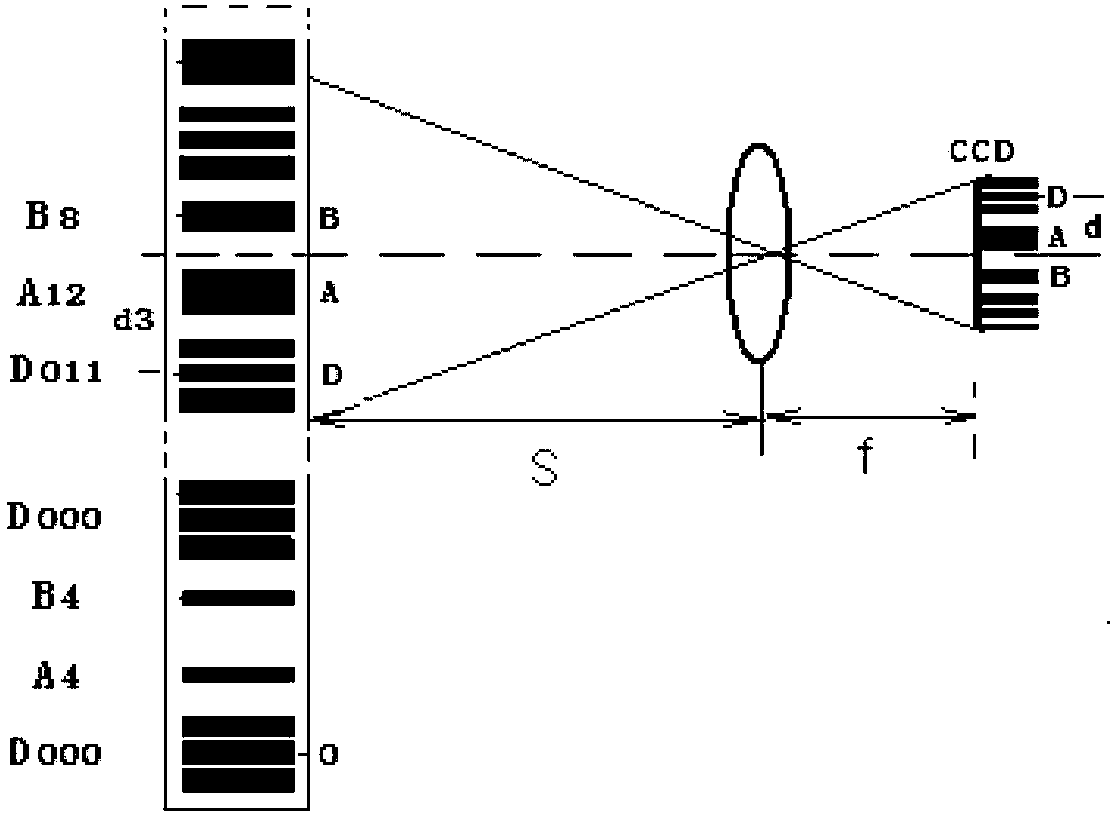

Phase grade self-coding-based optical three-dimensional measurement method

InactiveCN102322823AGet the absolute phase distributionRealize measurementUsing optical meansThree dimensional measurementFace shape

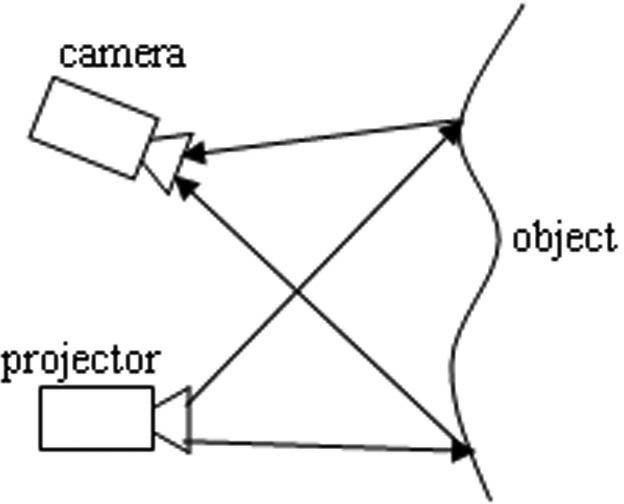

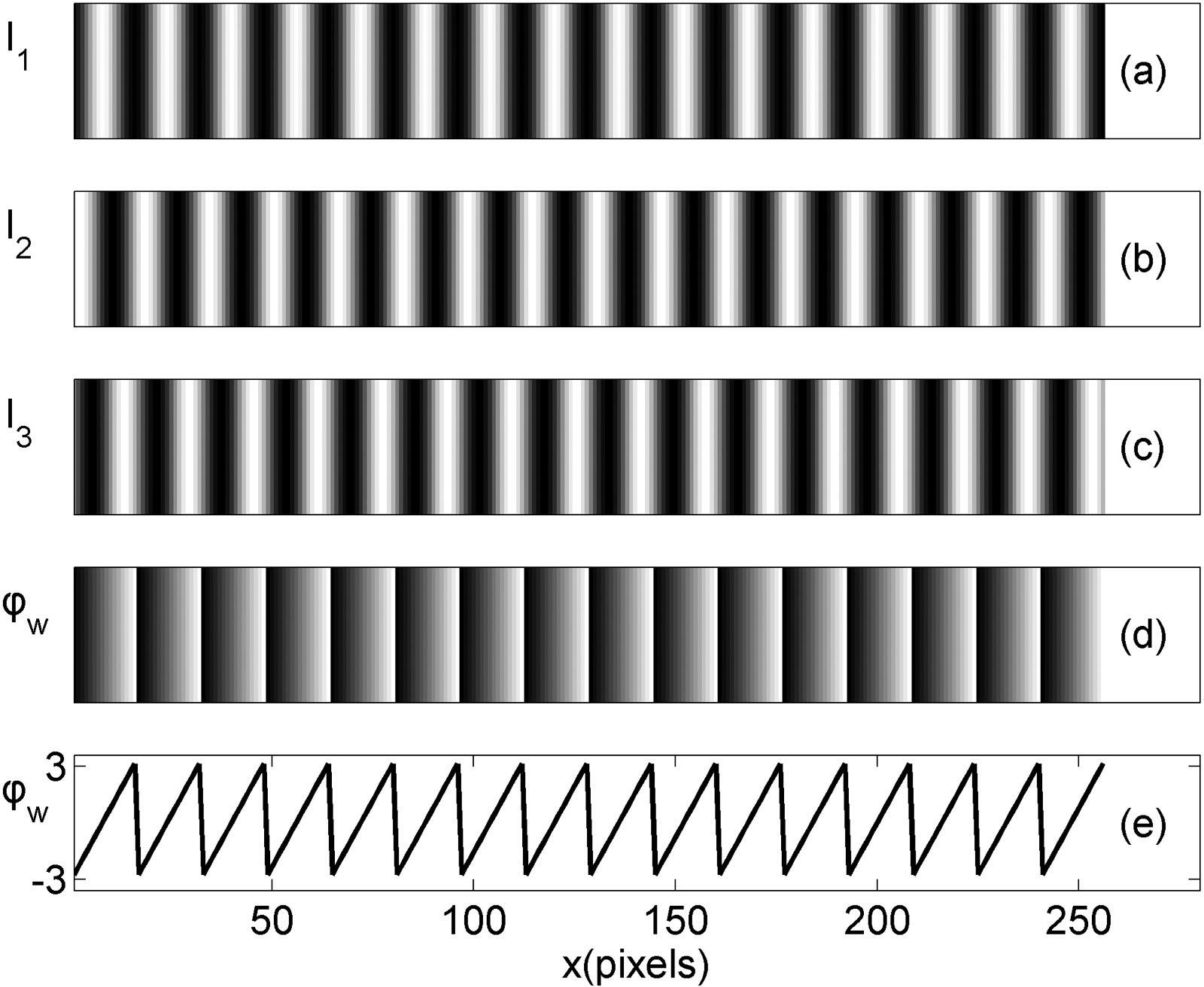

The invention discloses a phase grade self-coding-based optical three-dimensional measurement method. In the traditional phase measurement technology, generally additional coding patterns need to be projected to realize three-dimensional profile measurement of an isolated object. The method comprises the following steps of: providing sinusoidal stripes, the digital projection of which has phase grade coding information; constructing a code sequence, the total length of which is equal to the projected stripe period sum, by using the differential value or the slope value of phase distribution as a coding channel and using each stripe period as a coding unit; constructing a code sub sequence by using a plurality of adjacent periods; searching the position of the code sub sequence in the total code sequence to determine the phase grade of the period so as to obtain absolute phase distribution of the object to be measured; and finally, reconstructing a three-dimensional profile of the object to be measured according to the phase height relationship. The method can complete three-dimensional information acquisition of the object without projecting the additional coding patterns, and is particularly suitable for quick three-dimensional profile measurement of the isolated object.

Owner:SICHUAN UNIV

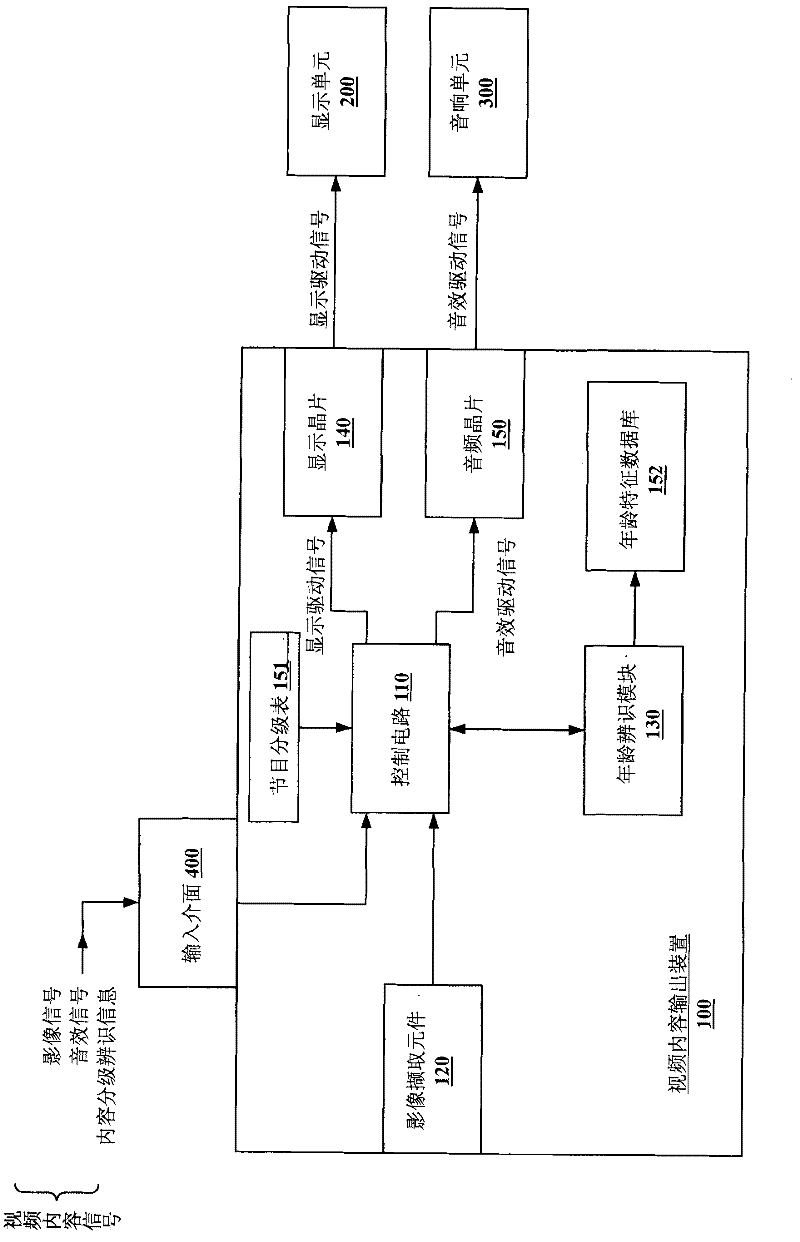

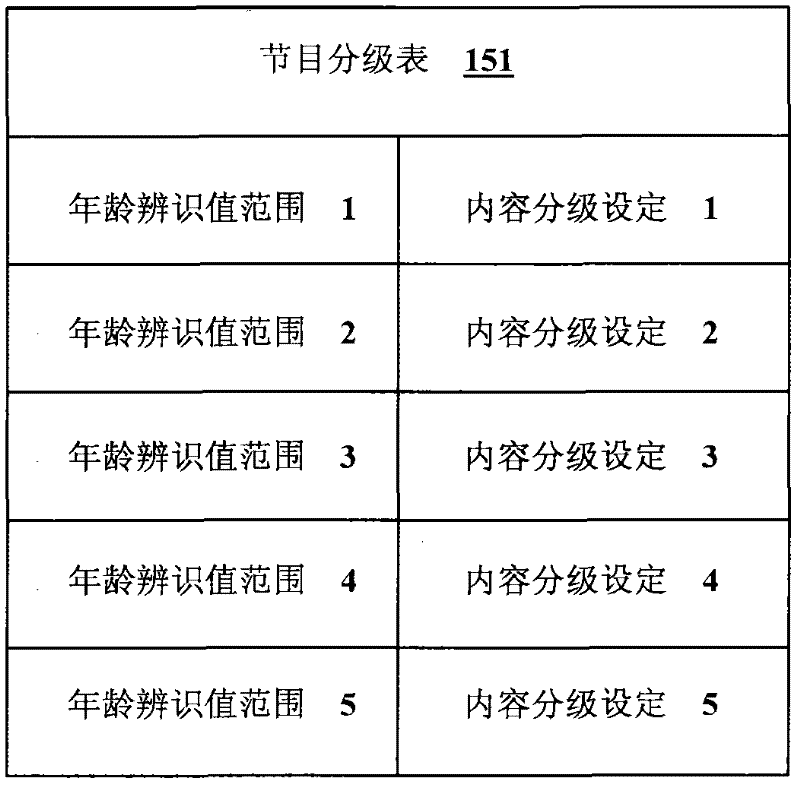

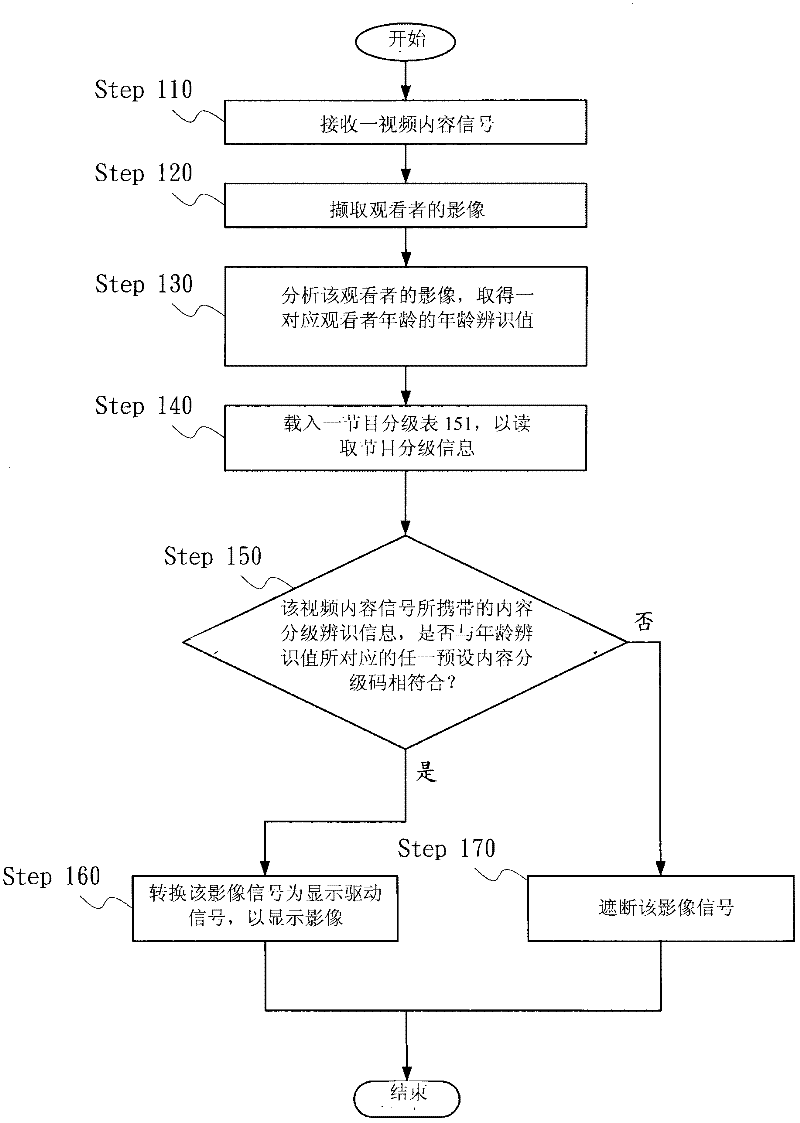

Video content output device and method capable of filtering video contents according to looker age

InactiveCN102547271APrevent outflowAvoid failureCharacter and pattern recognitionTelevision systemsOutput deviceControl circuit

The invention relates to a video content output device for filtering video contents according to looker age. The device comprises an image capturing assembly, an age distinguishing module and a control circuit, wherein the control circuit receives an image signal and content grade distinguishing information; the image capturing assembly is used for capturing the image of a looker so that the age distinguishing module can analyze the image of the looker to obtain an age distinguish value corresponding to the looker age; the control circuit loads multiple age distinguishing value ranges and preset content grade codes corresponding to the age distinguishing ranges and judges whether content grade distinguishing information accords with the preset content grade codes corresponding to the age distinguishing values;, if so, the control circuit converts the image signal to a display driving signal and outputs the display driving signal to a display unit to display the image.

Owner:HANNSPREE INC

Status assessing system of vehicle

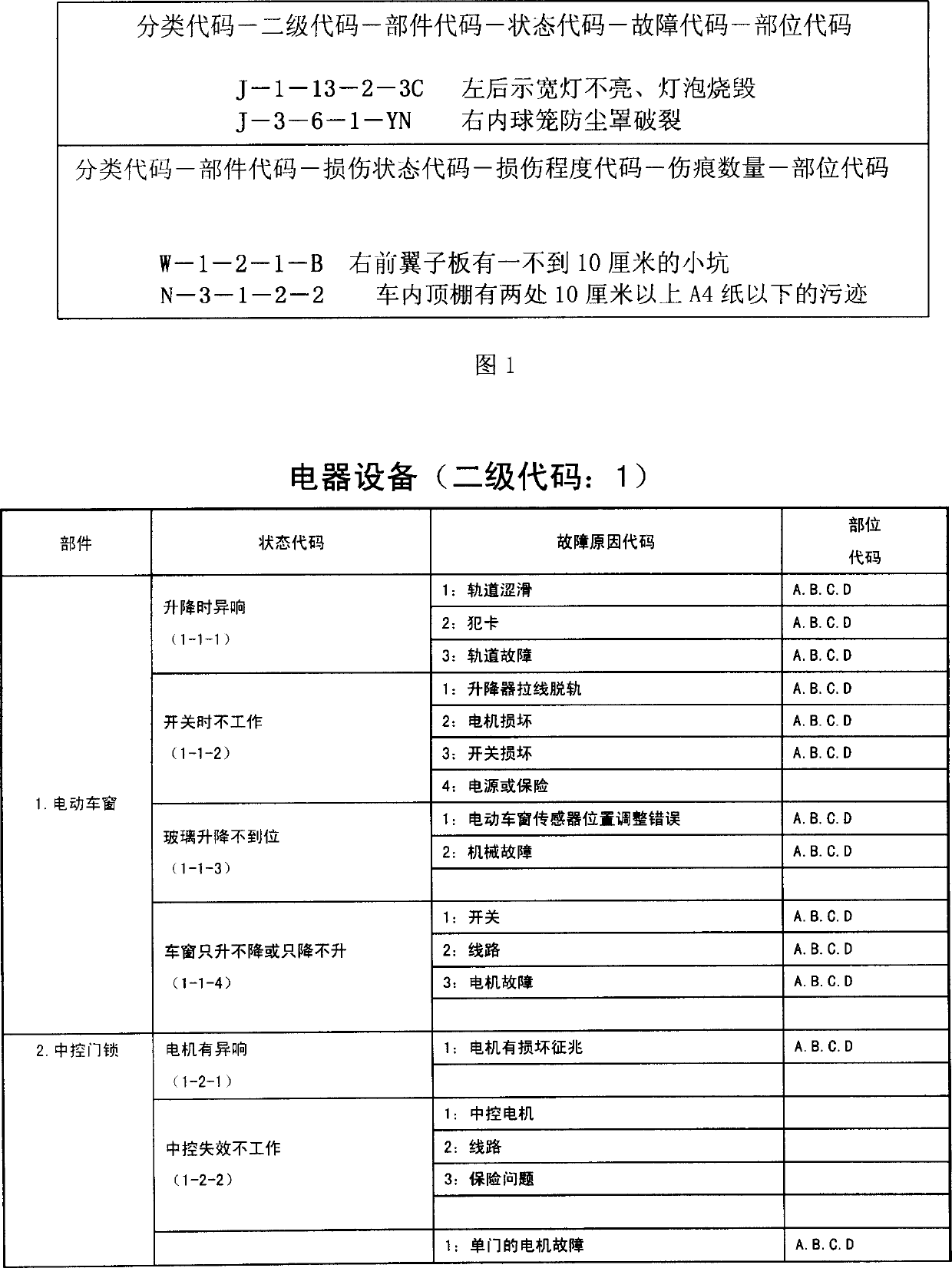

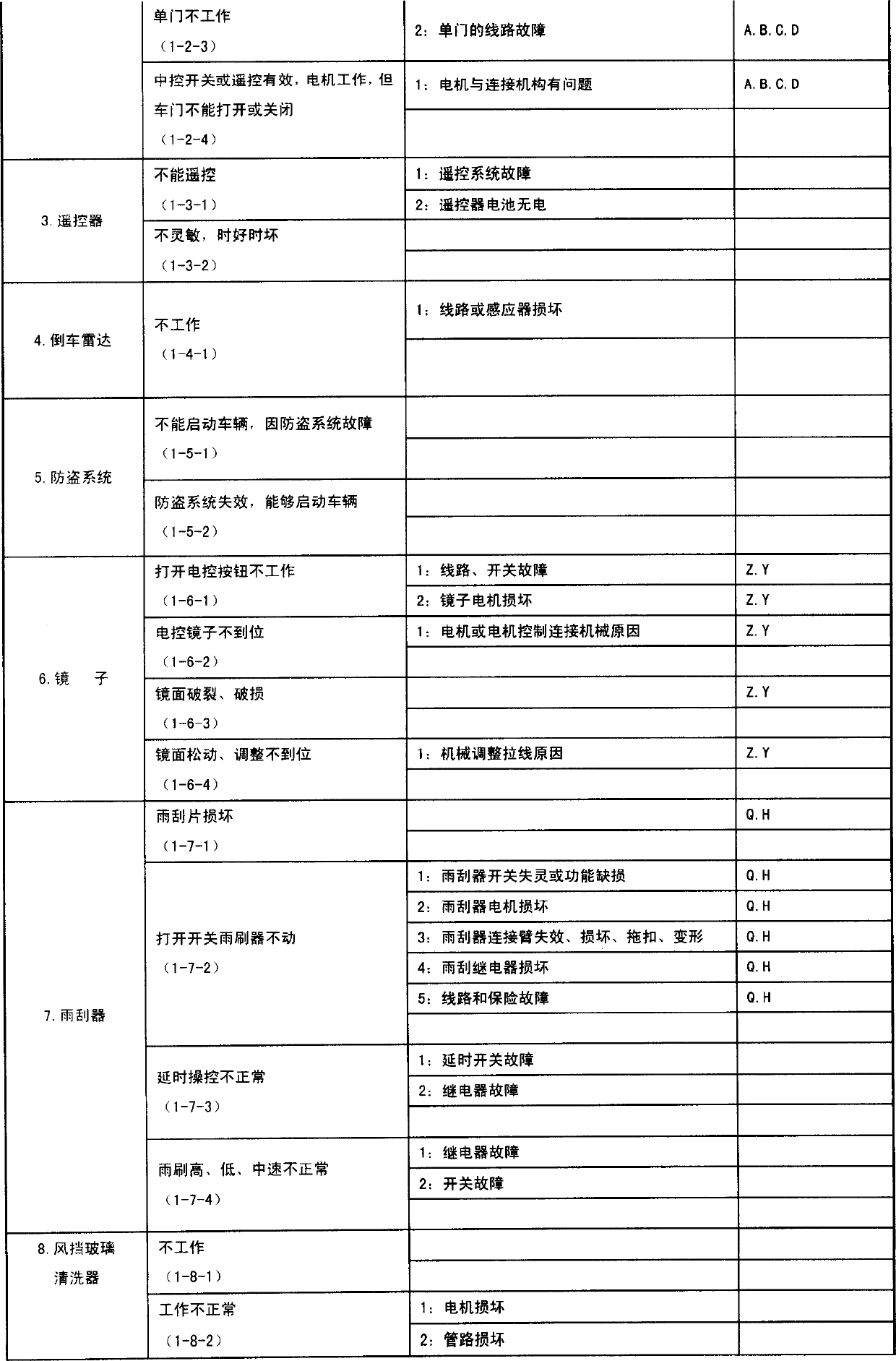

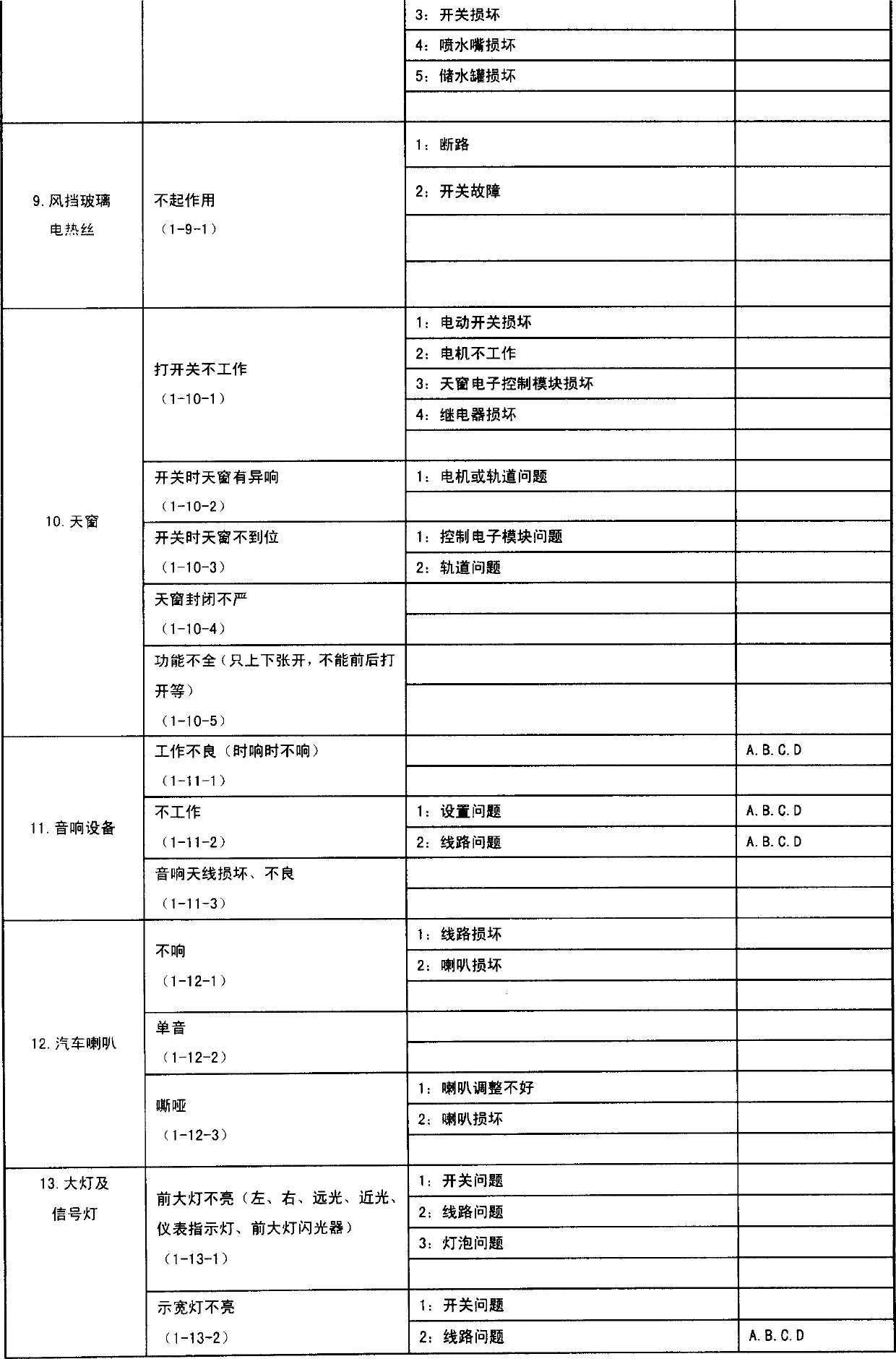

InactiveCN1818967AEasy for remote transferMarketingSpecial data processing applicationsClass CodeEvaluation system

A estate evaluating system of automobile vehicles, it is classifying the vehicles various parts extant condition such as breakdown into a special tree-form delamination, and endue the corresponding code to form the evaluating code of the system special disciplinarian: the classified code-the second-class code-the parts code-the estate code-the fault code-the position code or the classified code-the parts code-the scathing estate code-the scathing grade code-the scar code-the position code, that may record the estate of the second-hand automobile normatively, impersonally and scientifically, memorize and long-range send the estate code of the vehicles, demand the text explanation of the vehicle estate by the code that is convenient for the unified evaluating standard and scientific fix the price for the league shops of the second-hand vehicles.

Owner:TAIZHI CONSULTANT BEIJING

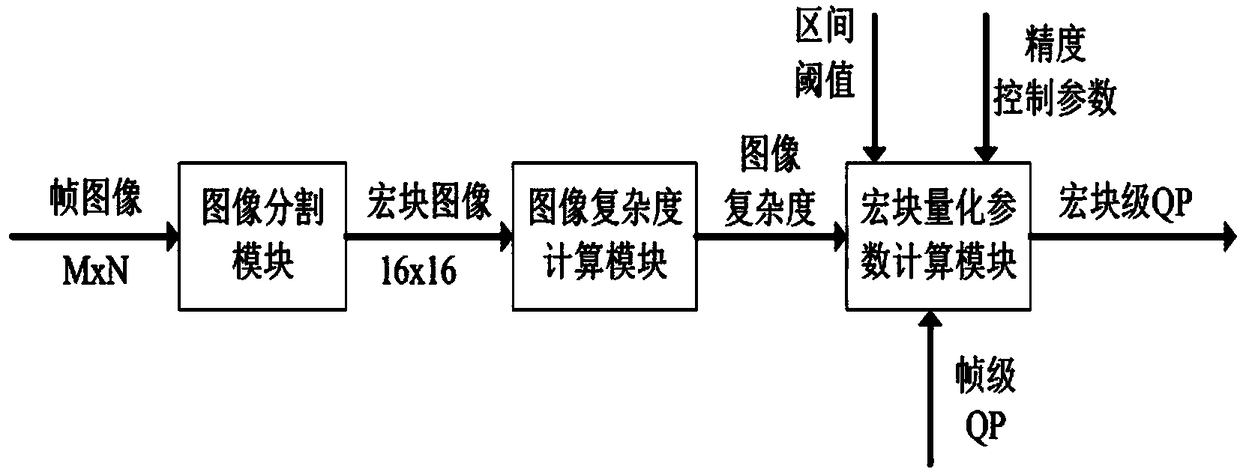

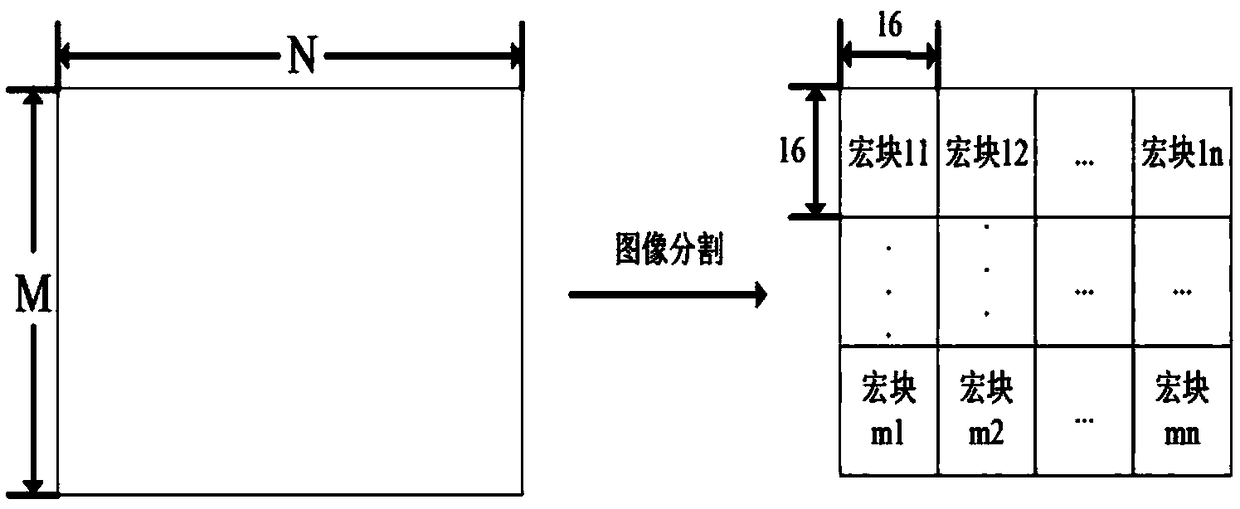

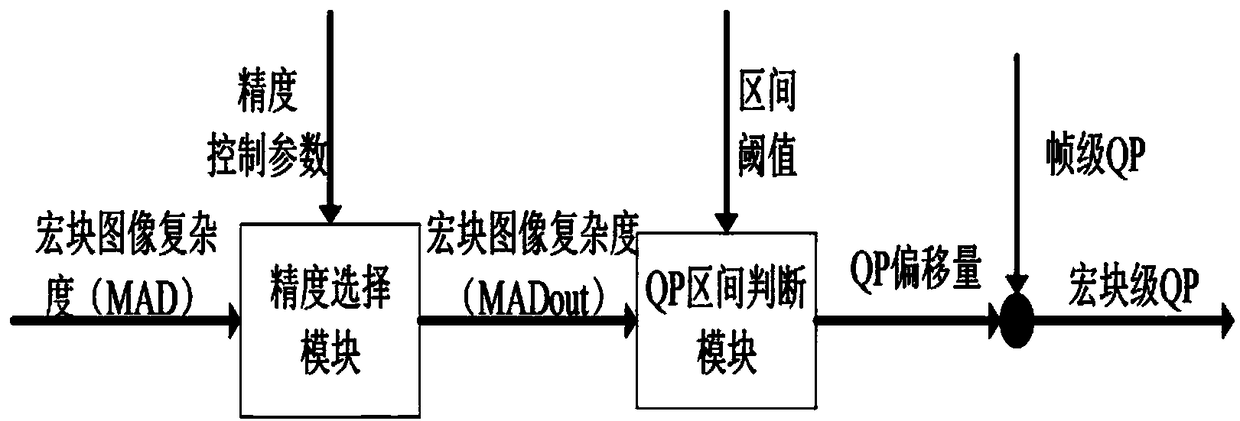

Adaptive macro-block grade code rate control system and control method for video compression

InactiveCN108174210AHigh precisionImproved image quality for uniform performance resultsDigital video signal modificationControl systemAlgorithm

The invention relates to an adaptive macro-block grade code rate control system and control method for video compression. The adaptive macro-block grade code rate control system for video compressionincludes an image segmentation module which is used for segmenting one frame of image into 16*16 macro-blocks, an image complexity calculation module which is used for inputting the segmented macro-blocks into the mage complexity calculation module and calculating the fluctuation change frequency of the image pixel value in the macro-block domain by calculating the absolute error sum of the pixelvalue in the frame of image and the pixel value in the area so as to obtain the image complexity MAD, and a macro-block quantization parameter calculation module which includes a precision selection module and a QP section determination module, wherein the preset section threshold, the precision control parameter and the image complexity MAD are input into the precision selection module to calculate the precision; and the macro-block image complexity MADout having determined the precision is sent to the QP section determination module to determine the QP section to which the macro-block belongs and calculate the macro-block QP offset, and the macro-block grade QP value can be obtained by stacking the frame grade QP with the macro-block QP offset, and then the adaptive macro-block grade code rate control can be realized.

Owner:杭州雄迈集成电路技术股份有限公司

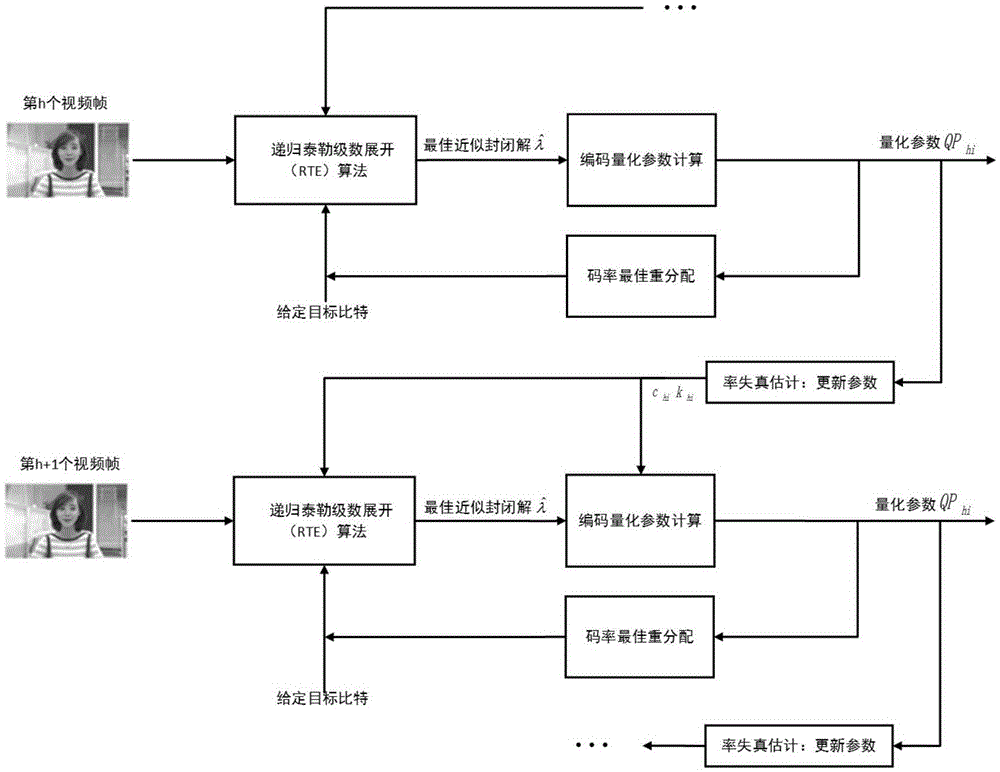

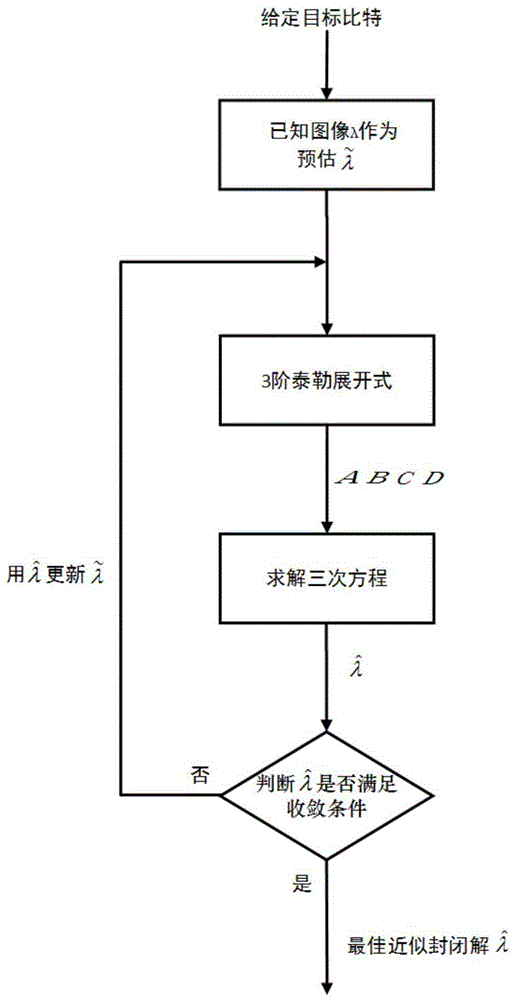

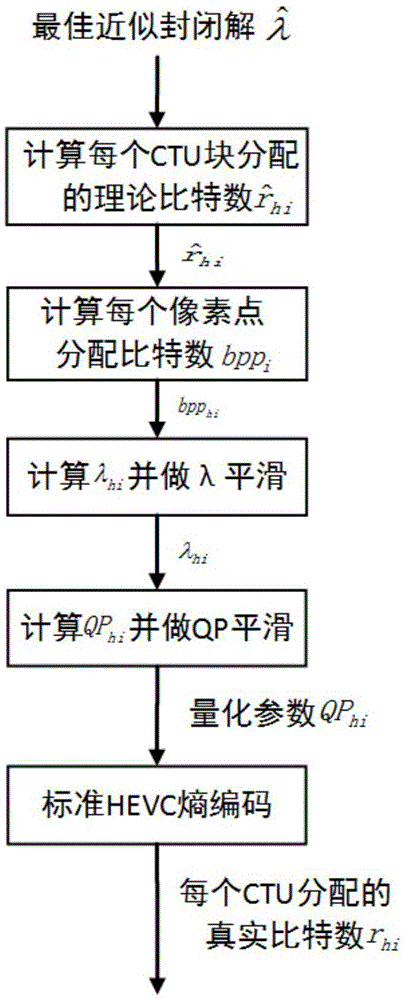

HEVC (High Efficiency Video Coding) CTU (Coding Tree Unit) grade code rate control method based on optimal bit allocation

ActiveCN105430395AImprove overall performanceIncreased coding complexityDigital video signal modificationHigh rateBit allocation

The invention discloses an HEVC (High Efficiency Video Coding) CTU (Coding Tree Unit) grade code rate control method based on optimal bit allocation, and belongs to the field of video coding. In particular, a new R-D estimation is provided to replace an existing R-lambda estimation, and an optimal bit allocation equation is deduced through the new R-D estimation, thereby realizing optimal bit allocation for an R-lambda code rate control model on a CTU. Furthermore, a recursive Taylor expansion algorithm is provided to solve the originally-unsolvable equation at a very high convergence speed, thereby obtaining an approximate closed-form solution, and realizing optimal bit allocation. Meanwhile, a method for performing optimal bit reallocation on remaining bits is provided through the recursive Taylor expansion algorithm. The code rate control method is a first algorithm for realizing HEVC optimal bit allocation at very low coding complexity. The code rate control method has the advantages of higher rate distortion, higher RC accuracy and higher robustness in dynamic picture change compared with other existing R-lambda code rate control models.

Owner:BEIHANG UNIV

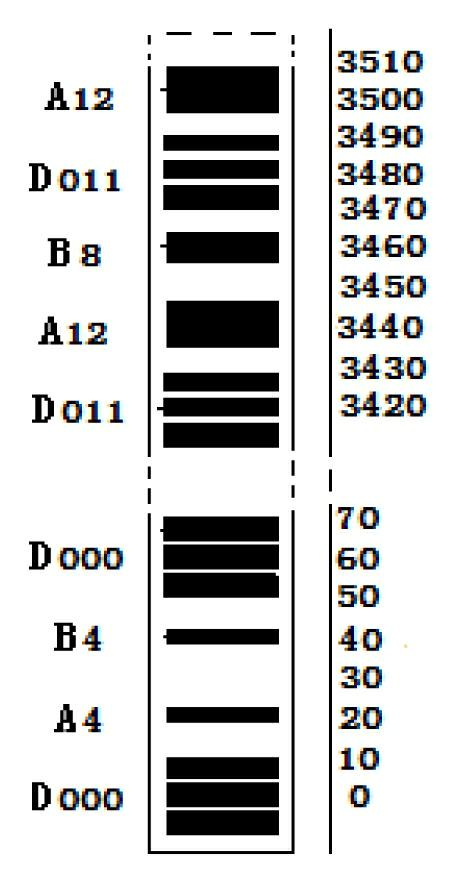

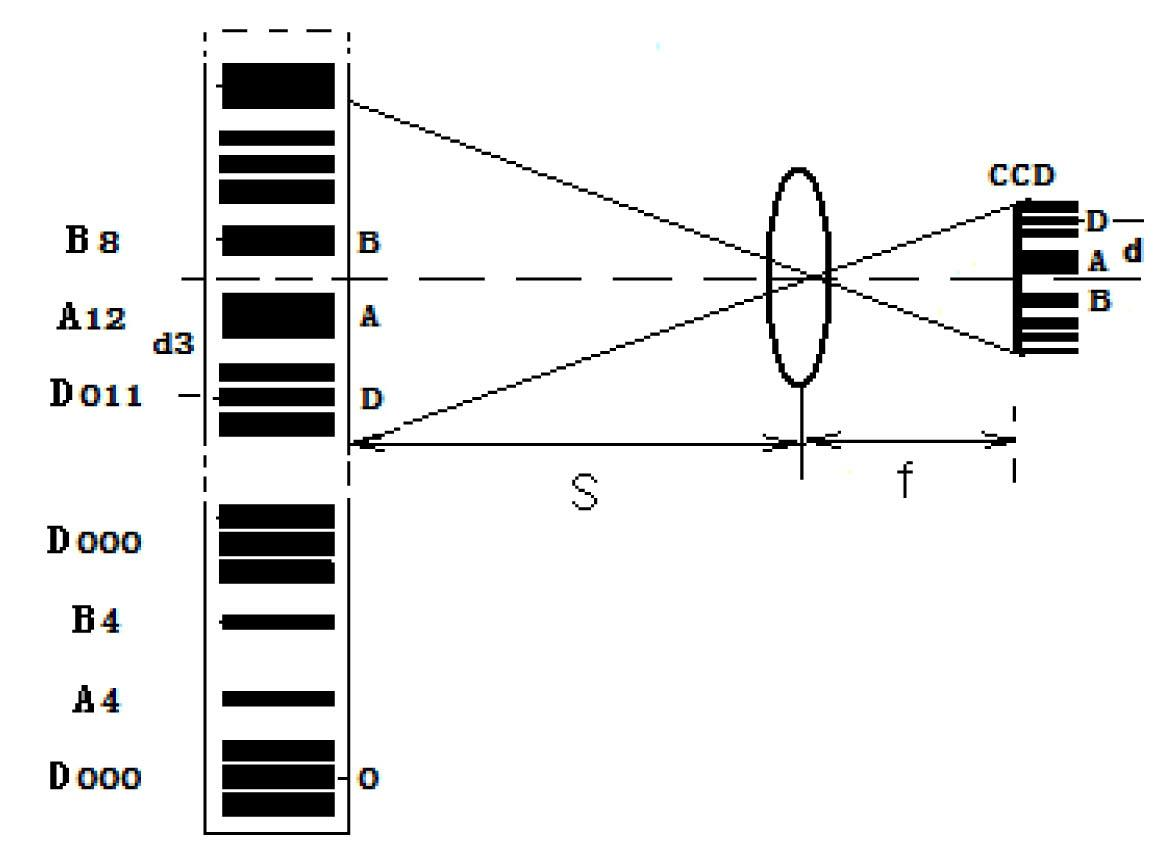

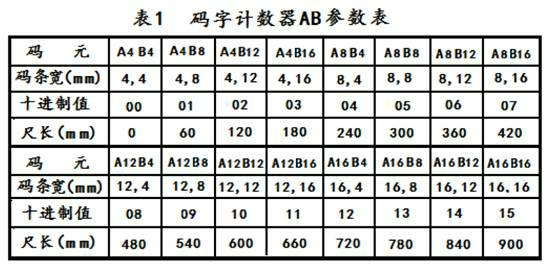

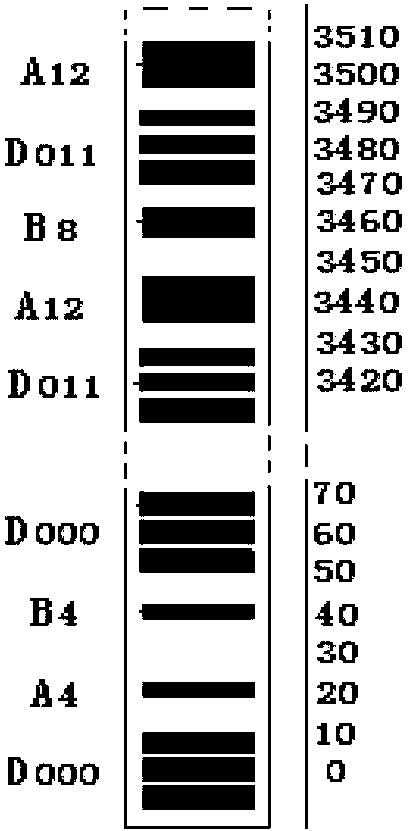

Bar gauge by grading coding

InactiveCN102494669AReduce the difficulty of identificationLow barcode densityHeight/levelling measurementMeasuring instrumentBarcode

A bar gauge by grading coding relates to the technical field of measuring instrument. According to the invention, the technical problem of high difficulty of present bar gauge identification is solved. Scale of the bar gauge provided by the invention is equally divided into a plurality of code segments. Each code segment is divided into a plurality of code words. Each code word is equally dividedinto D code element, A code element and B code element. The distances between centers of adjacent code elements are consistent. The D code element has a plurality of code bars, which are centrosymmetrically distributed to form a code segment counter. There is only one code bar at the center of the A code element and the B code element. The A code element and the B code element form a code word counter. The center line of the D code element is the start point of code words as well as the stop point of the front code word. There are a plurality of code bars in the D code element. Code segment counter values in the same code segment are consistent and convenient to identify. The bar gauge provided by the invention is characterized by few combinations of code elements and low bar code density. Wide-range levelling can be realized by using few combinations of code elements. Good conditions are created for long-distance measurement of barcode positioning, and measurement reliability is raised.

Owner:谢佑坤 +3

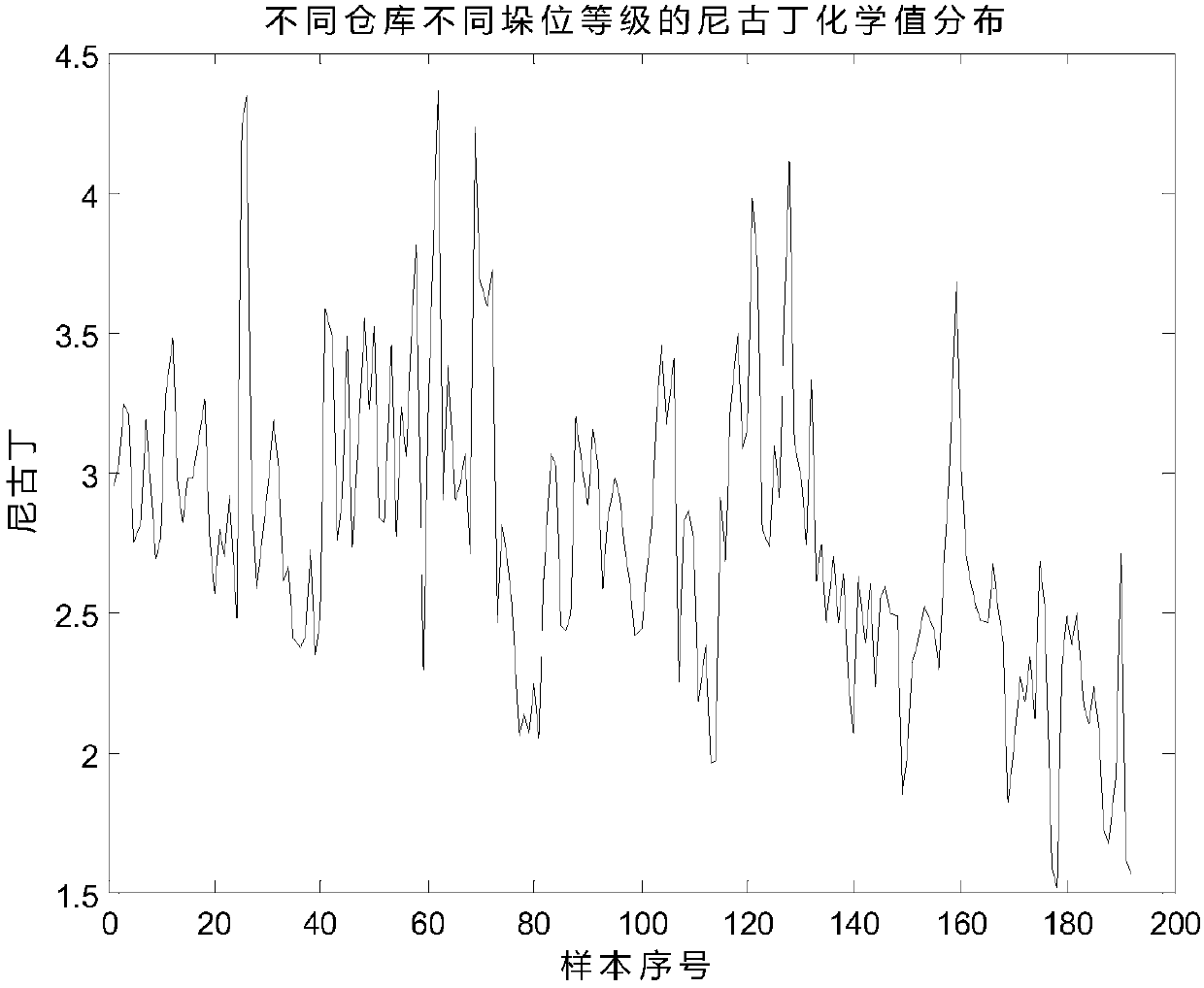

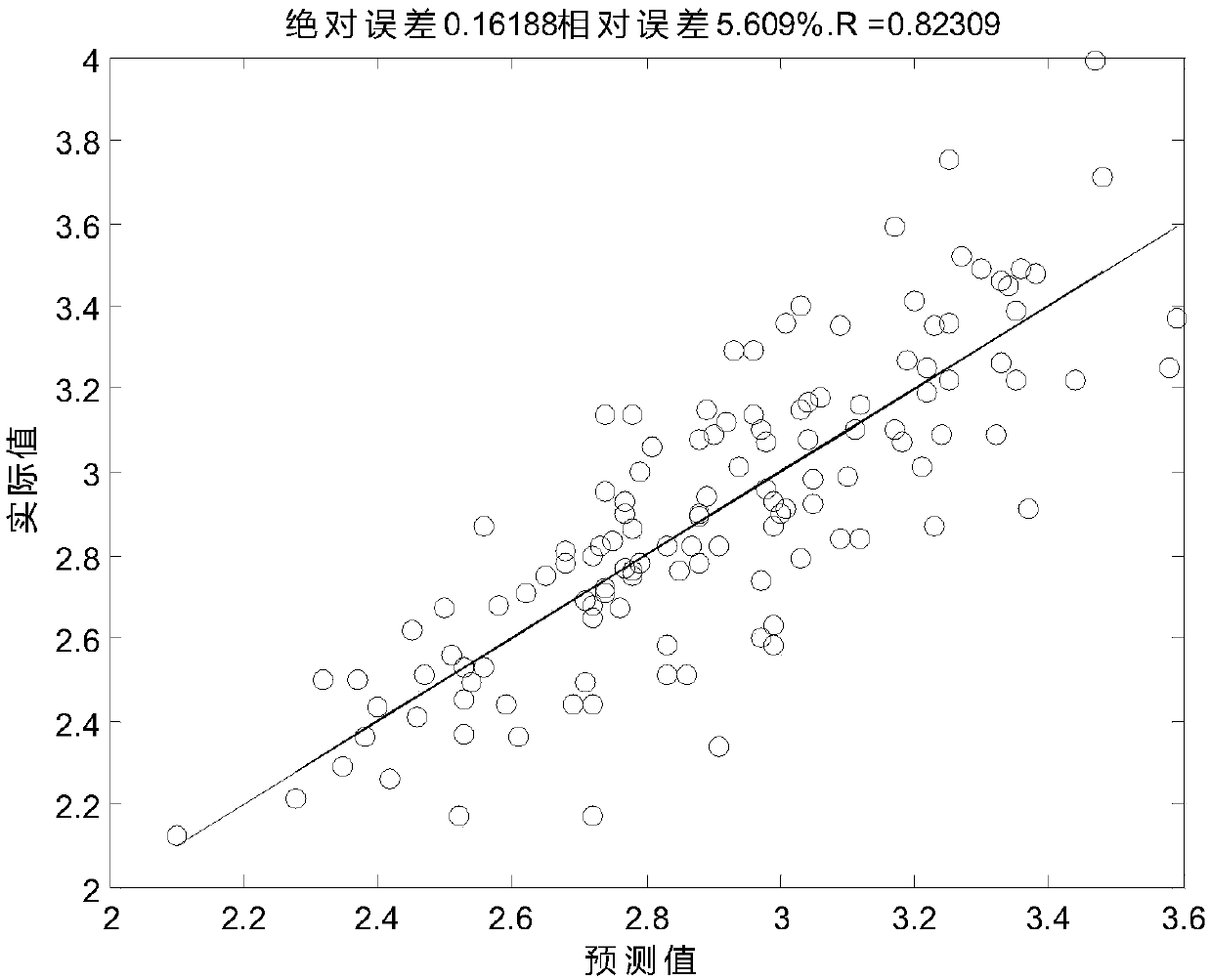

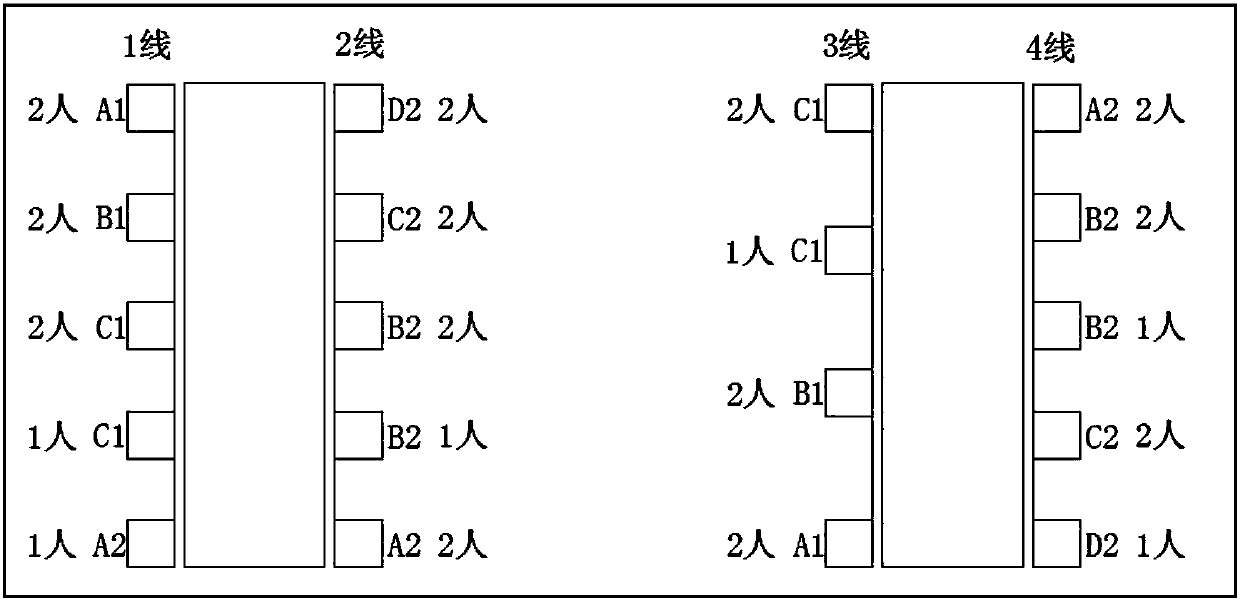

Sectional homogenizing regulating and controlling method based on original tobacco formula module splitting

ActiveCN107897995AWill not affect the trend of chemical valueWeaken the effect of homogenizationTobacco preparationChemical indexEngineering

The invention provides a sectional homogenizing regulating and controlling method based on original tobacco formula module splitting. The regulating and controlling method comprises the following steps: 1) determining the location of a tobacco warehouse; 2) acquiring chemical value of a sample and calculating an average value; 3) selecting regulating and controlling indexes C; 4) performing descending sort on the regulating and controlling indexes C, so that K equal diversion points of a grade proportion are obtained, wherein a new grade marking code, namely G1, G2 and so on, is formed by eachequal diversion point; 5) sequentially placing and detecting G1, G2 and so on; and dividing an interval of the chemical index C corresponding to each grade code Gi into m intervals in the warehouse by a method as follows: calculating an average weight proportion weighted chemical value MGi of the grade Gi and forming the first interval with the average value MGi as a center and delta as a step length, expanding towards two sides, and marking as Ai, Bi until Mi; and 6) calculating the number of tobacco boxes NAi, NBi until NMi of Ai, Bi until Mi of each interval as well as proportions pAi, pBiuntil pMi of each tobacco box number, so that the number of delivered tobacco boxes in each interval is W*(pAi, pBi until pMi). With the application of the regulating and controlling method, the influence of unevenness of leaf paving on homogenizing regulating and controlling is relieved.

Owner:SHANGHAI MICRO VISION TECH

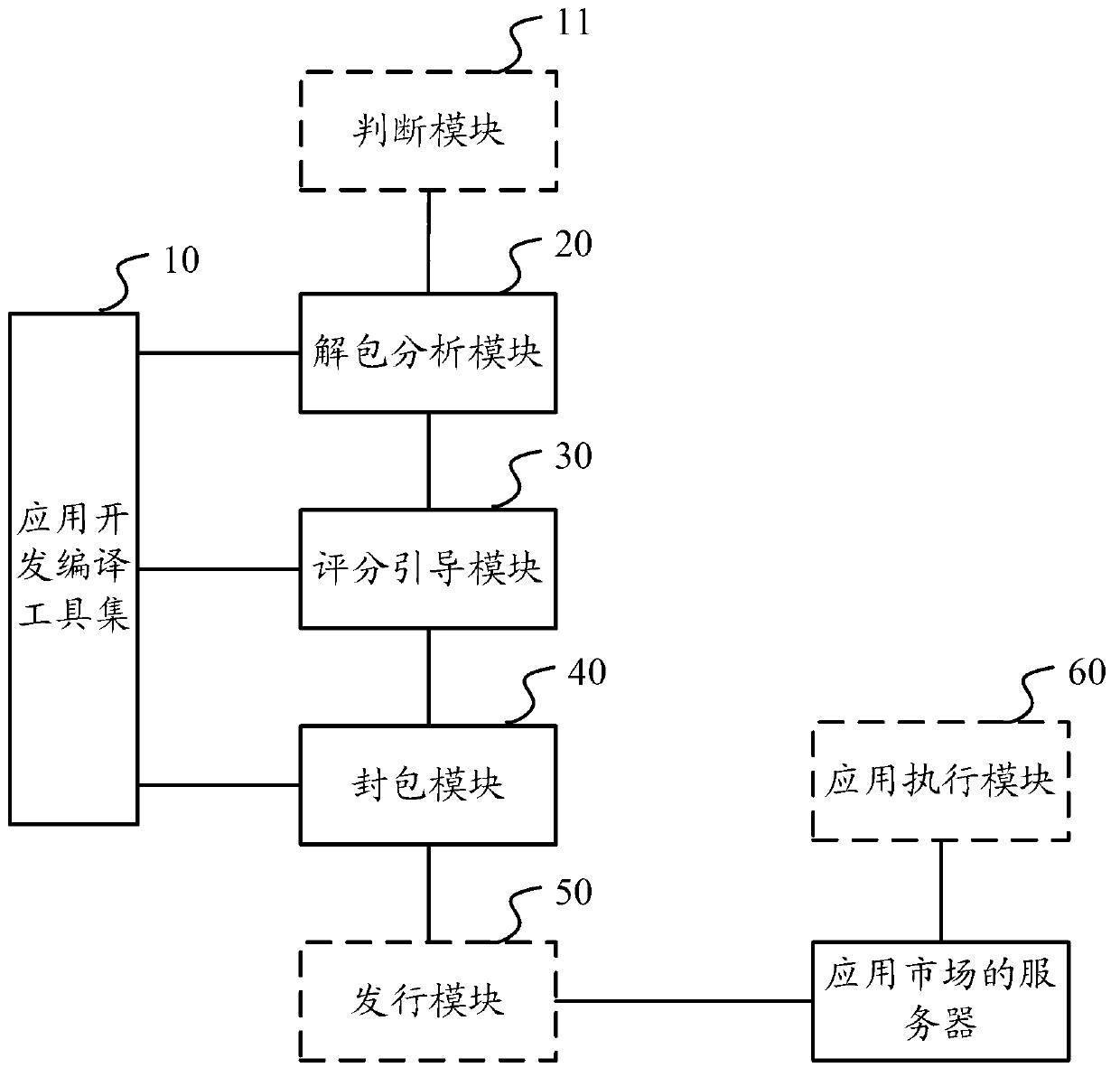

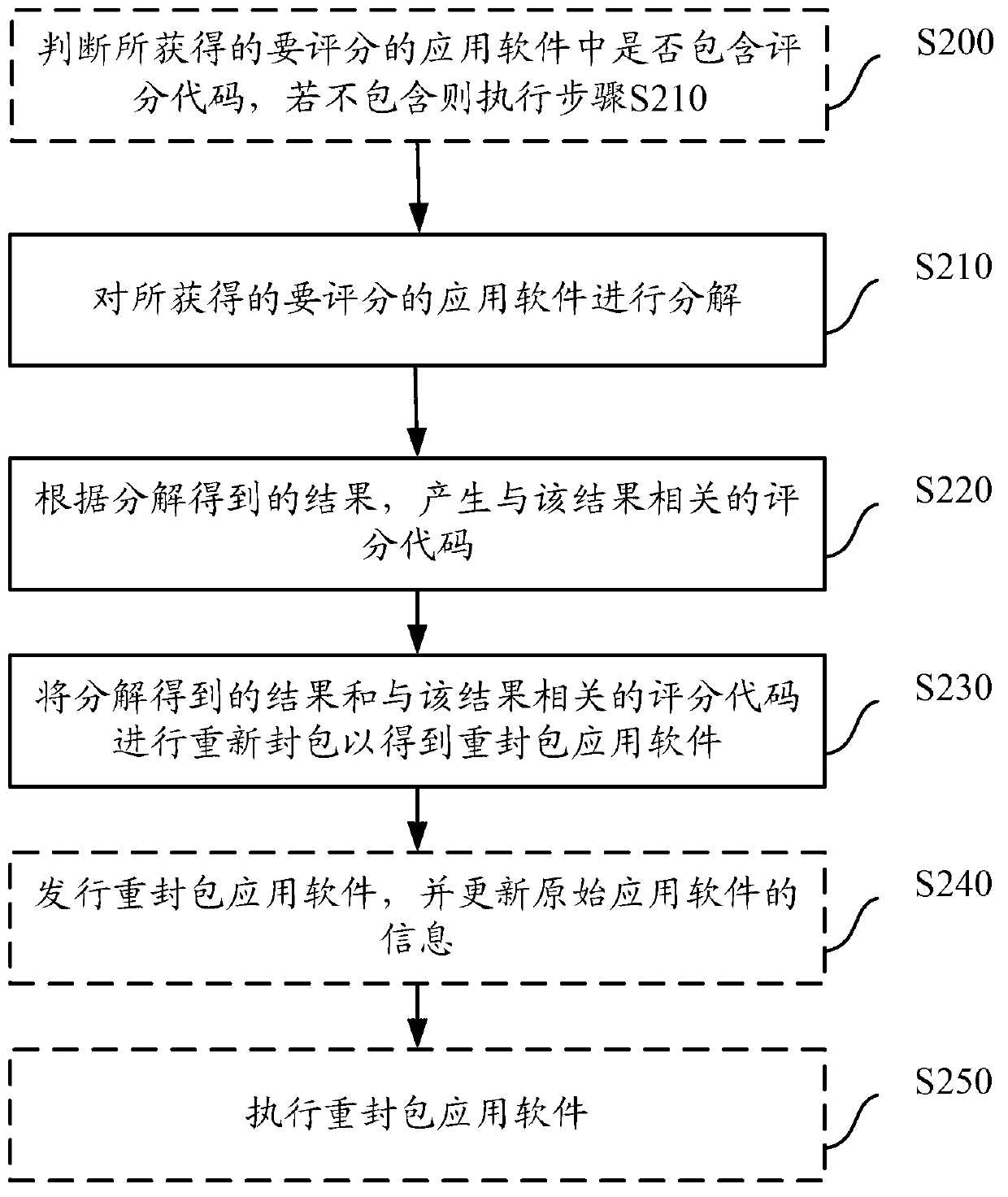

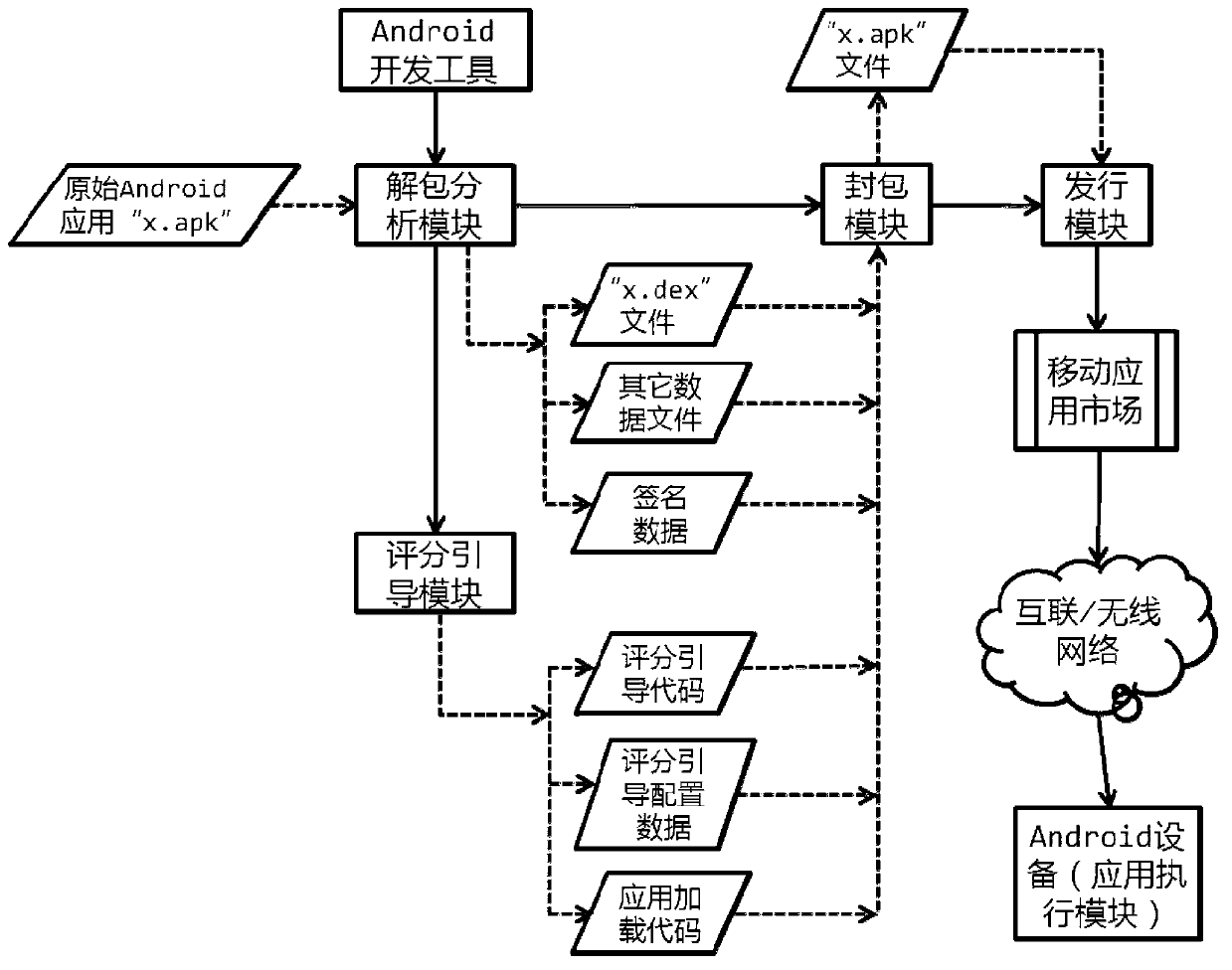

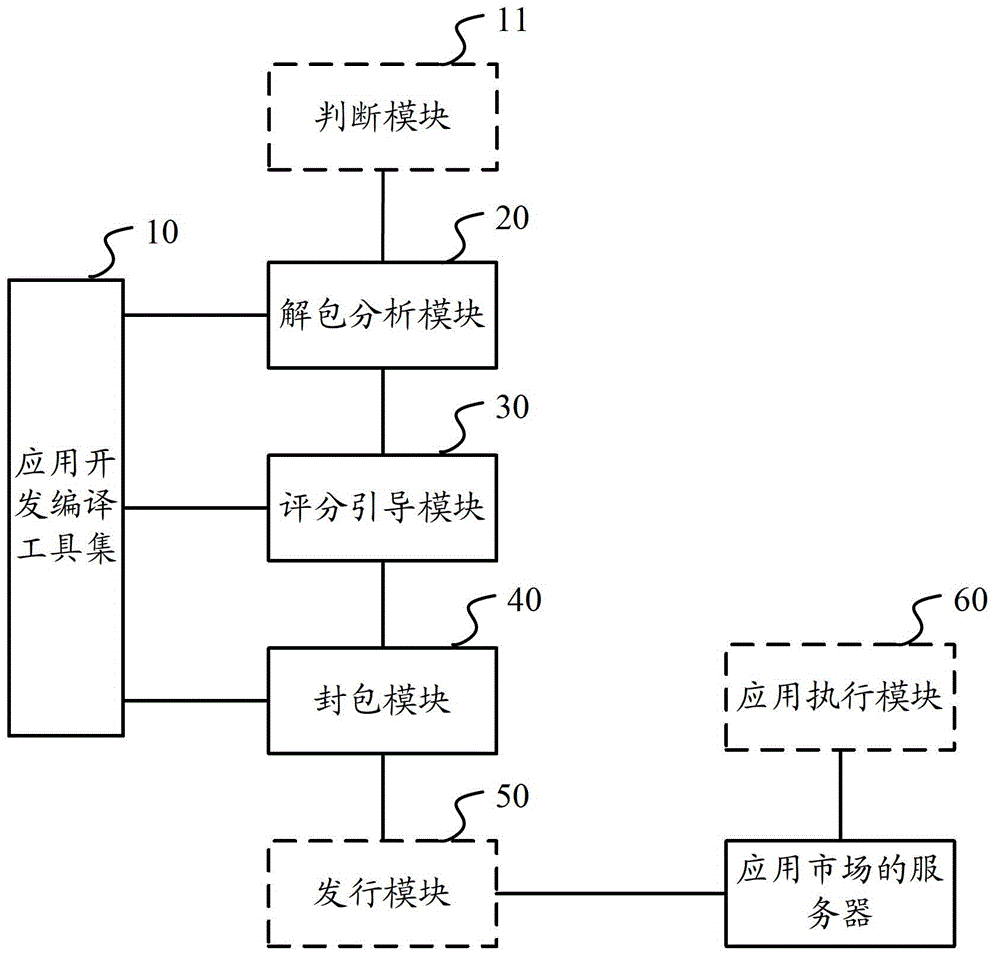

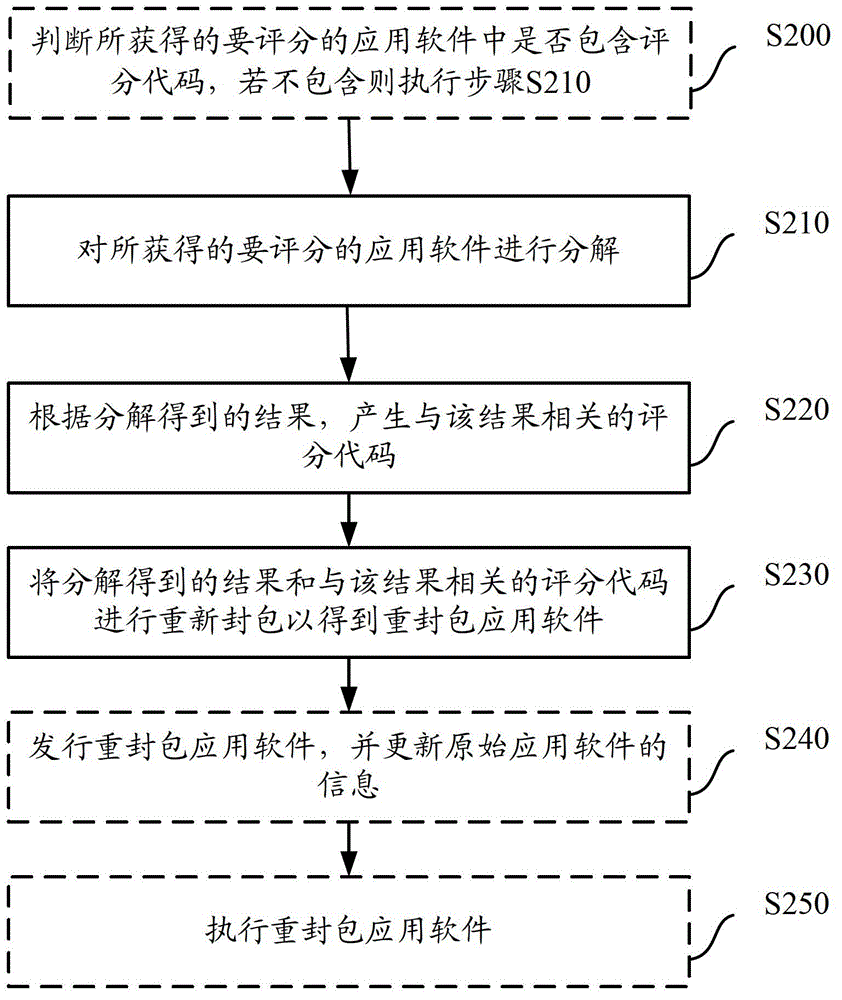

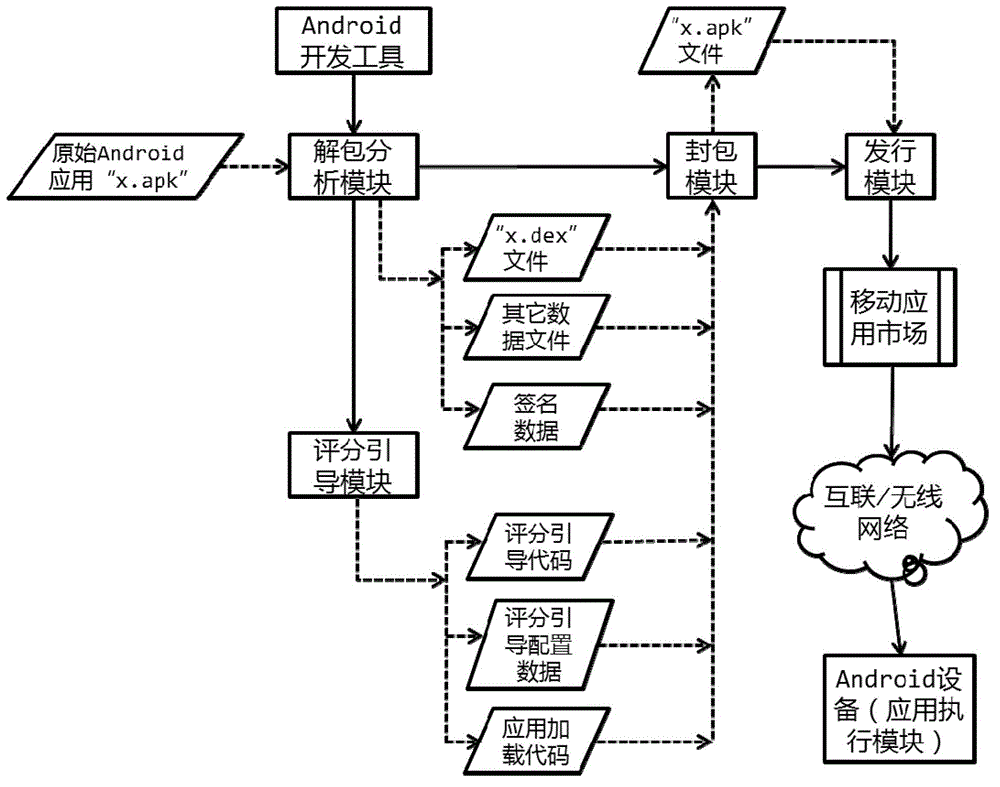

Grading method and system for application software

The invention discloses a grading method for an application software, which comprises the following steps: obtaining: obtaining a to-be-graded application software; unpacking and analyzing: decomposing the application software to obtain a decomposing result containing an executable file part and a data file part; grading guiding: generating a grading code related to the result according to the decomposing result; and packaging: re-packaging the decomposing result and the grading code to obtain an application software with a grading function and marking the application software as the re-packaged application software, wherein when the re-packaged application software is used by a user, the grading code is executed, so as to guide the user to grade the to-be-graded application software. According to the grading method and the system for the application software, an added grading guiding program is combined with the application software, so that the grading guiding program runs at a specific moment when the application is executed by the user on an intelligent terminal, so as to guide the user to a mobile application market for grading the application.

Owner:BEIJING FEILIU JIUTIAN TECH CO LTD

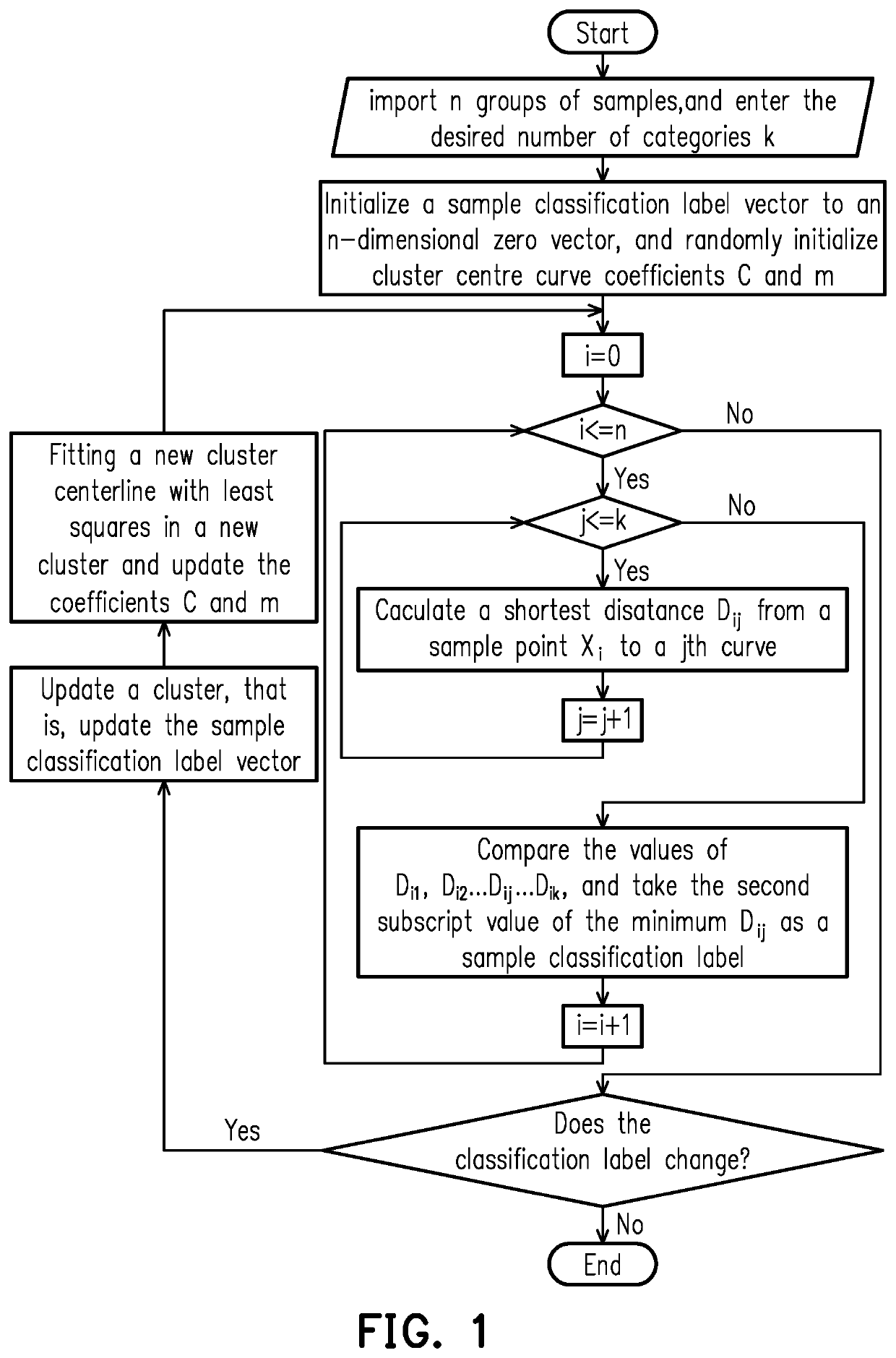

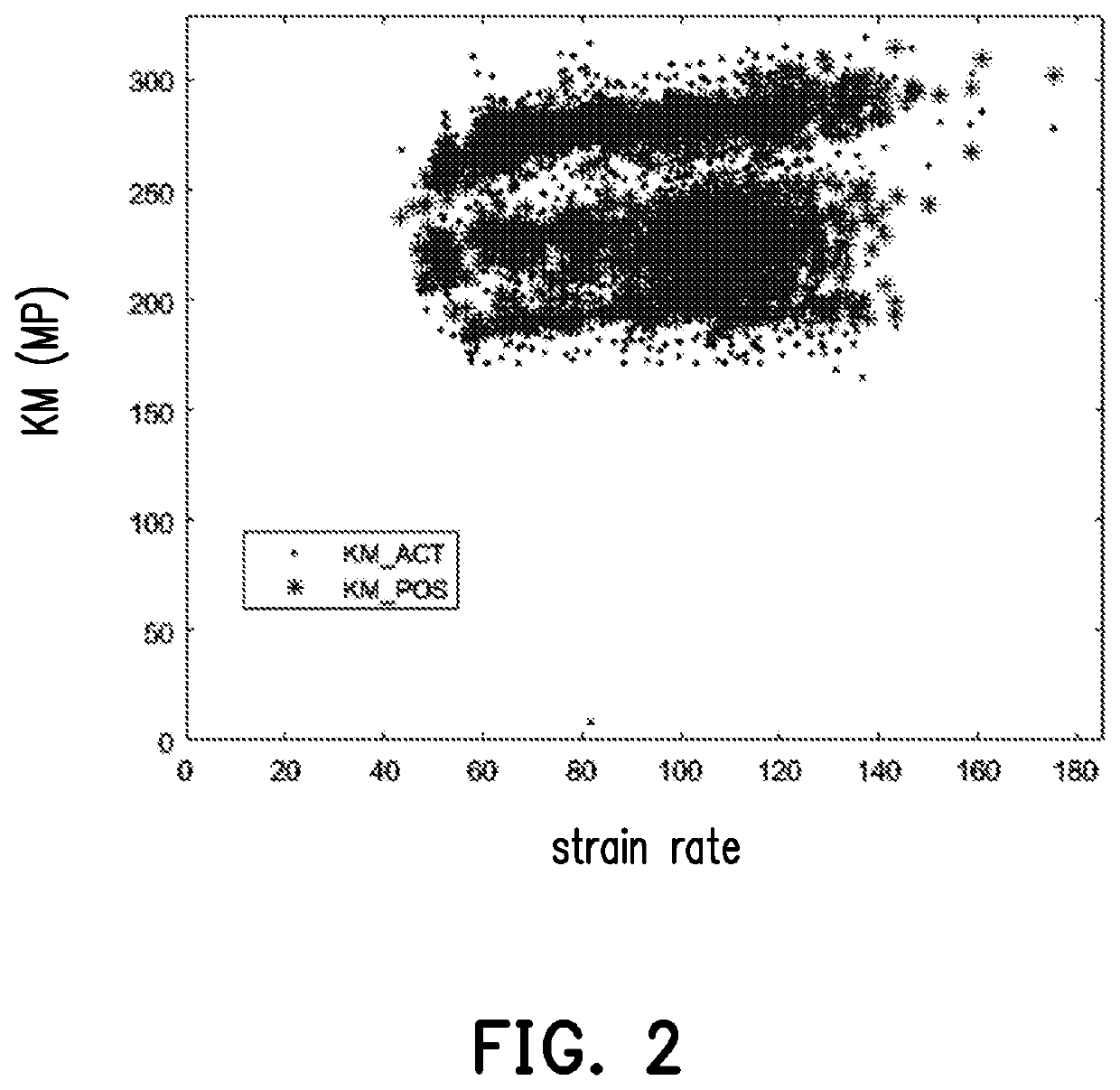

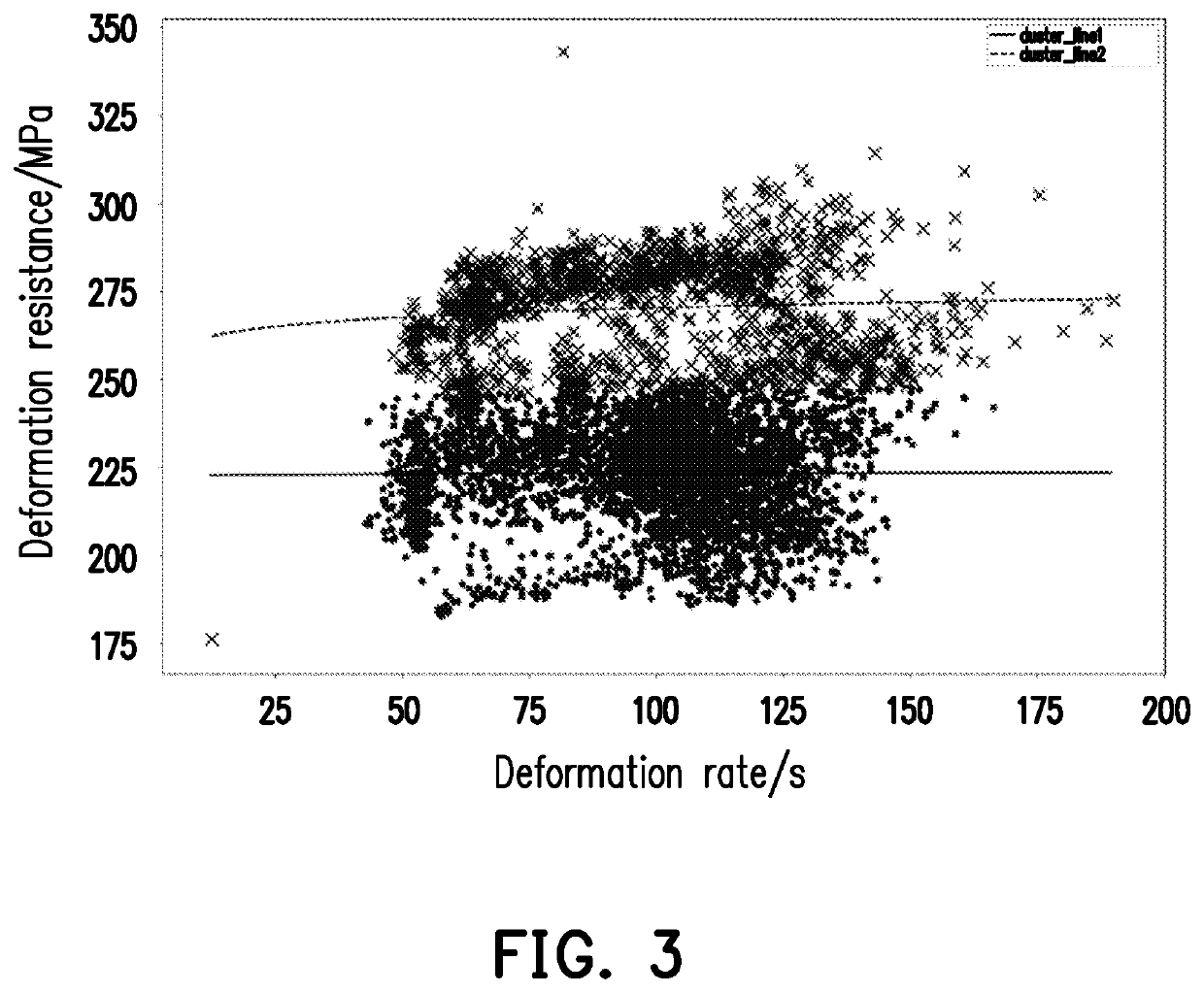

Classification optimization method for steel grade family of steel rolling model

ActiveUS20190377841A1High precisionImproving model setting precisionMeasuring devicesDesign optimisation/simulationShortest distanceNelder mead algorithm

Provided is a classification optimization method for steel grade family of a steel rolling model, including: step 1: calculating the deformation rate and deformation resistance of a rolled piece according to rolling process data; step 2: reversing the “equivalently measured” deformation resistance according to the measured roll force; step 3: drawing a scatter plot of data on a graph, and judging whether layer division is reasonable according to distribution characteristics; and step 4: for the unreasonable division of steel grade family, optimizing the existing classification of steel grade family using a new algorithm called line clustering, determining steel grade codes that need to be divided into new family, searching for the shortest distance from a sample point to the curve of each cluster centre based on a Nelder-Mead algorithm, dividing all data points into k subsets according to the principle of proximity, fitting a power curve to each data subset using a least square method, repeating the above steps, and stopping iterating when cluster centrelines obtained by two successive iterations are consistent. The present invention improves the precision of the division of steel grade family of a hot rolled model.

Owner:WUHAN UNIV OF SCI & TECH

Method for increasing thickness detection precision of stainless steel cold-rolling mill

ActiveCN103658196AAvoid errorsMeet production needsMeasuring devicesMetal rolling arrangementsControl systemAlloy

Disclosed is a method for increasing thickness detection precision of a stainless steel cold-rolling mill. The method is characterized by including the steps that steel grade codes and raw material manufacturers are combined to give serial numbers to steel grades, as for different raw material manufacturers which each steel grade corresponds to, corresponding thickness standard plates are respectively manufactured, and the standard plates are used for calibrating a thickness gauge so as to determine alloy compensation coefficients of the steel grades. Thereby, the different raw material manufacturers can be effectively distinguished, and errors of the detection precision of the thickness gauge due to original same steel grade mark but different raw material manufacturers can be avoided. By means of the method for increasing the thickness detection precision of the stainless steel cold-rolling mill, a control system of an existing stainless steel cold-rolling mill is fully utilized, special transformation and added devices are not required, producing requirements can be met, the thickness detection precision can be greatly improved, and the method is simple, practical and reliable.

Owner:NINGBO BAOXIN STAINLESS STEEL

Phase grade self-coding-based optical three-dimensional measurement method

InactiveCN102322823BGet the absolute phase distributionRealize measurementUsing optical meansThree dimensional measurementFace shape

The invention discloses a phase grade self-coding-based optical three-dimensional measurement method. In the traditional phase measurement technology, generally additional coding patterns need to be projected to realize three-dimensional profile measurement of an isolated object. The method comprises the following steps of: providing sinusoidal stripes, the digital projection of which has phase grade coding information; constructing a code sequence, the total length of which is equal to the projected stripe period sum, by using the differential value or the slope value of phase distribution as a coding channel and using each stripe period as a coding unit; constructing a code sub sequence by using a plurality of adjacent periods; searching the position of the code sub sequence in the total code sequence to determine the phase grade of the period so as to obtain absolute phase distribution of the object to be measured; and finally, reconstructing a three-dimensional profile of the object to be measured according to the phase height relationship. The method can complete three-dimensional information acquisition of the object without projecting the additional coding patterns, and is particularly suitable for quick three-dimensional profile measurement of the isolated object.

Owner:SICHUAN UNIV

A deep code obfuscation method for Android system applications

ActiveCN103544414BImprove securityGuaranteed confidentialityProgram/content distribution protectionBase codeObfuscation

Owner:JIANGSU PAYEGIS INFORMATION SECURITY TECH CO LTD

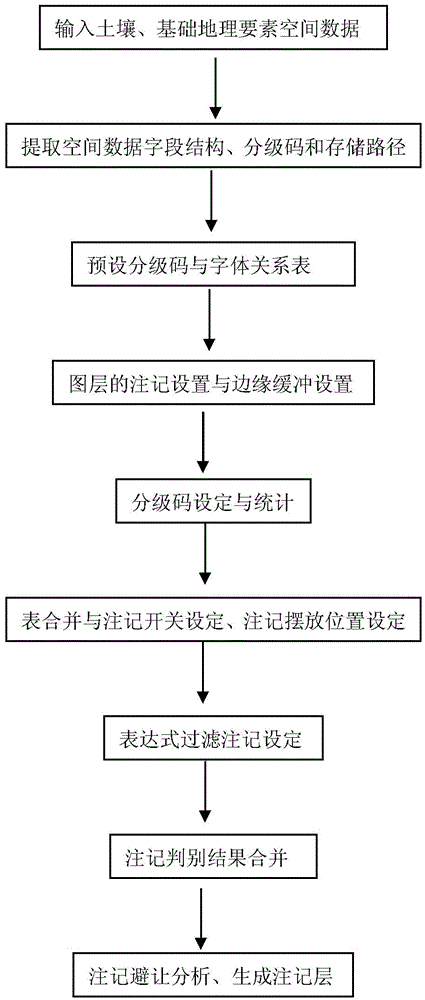

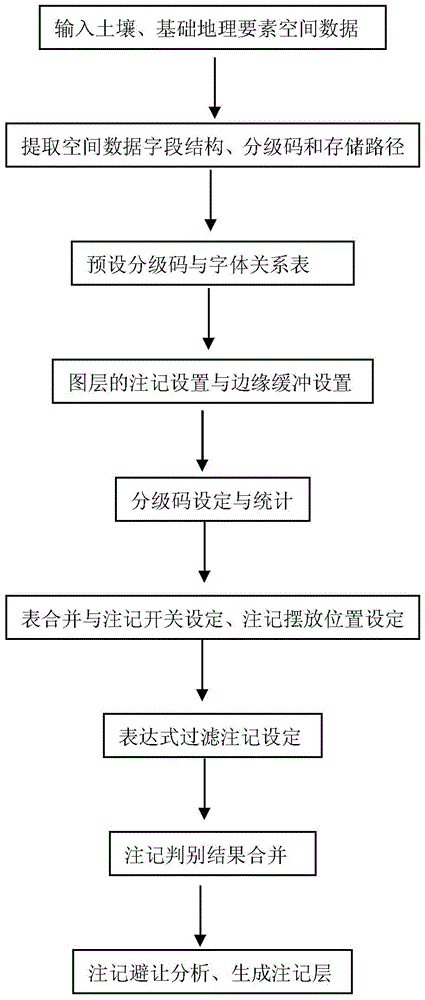

Method for generating notes of soil spatial data graph

InactiveCN104021211AAutomate processingSolve the problem of step judgmentGeographical information databasesSpecial data processing applicationsData graphTheoretical computer science

The invention discloses a method for generating notes of a soil spatial data graph. The method includes the first step of generating a structural table, a grading code table and a storage path table according to a database; the second step of establishing a grading code and typeface relational table V_GrTxt; the third step of carrying out note setting and edge buffering setting on a map layer according to the structural table, generating a table Vlay and selecting grading code fields needing counting to count grading codes; the fourth step of merging the grading code table with the table Vlay and the table V_GrTxt and generating a grading code table V2_Gr, wherein the grading code table V2_Gr is provided with a GrOff field determining whether notes are generated or not and a Curve field setting the arrangement direction in which the notes are generated; the fifth step of screening the grading codes in the table V2_Gr according to a statistic result and determining whether the grading codes generate the notes or not; the sixth step of merging distinguish results, generating a grading code table V4_Leg of the notes and generating a note layer according to the Curve field and the table V_GrTxt. The method achieves automatic receding and generation of the notes.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

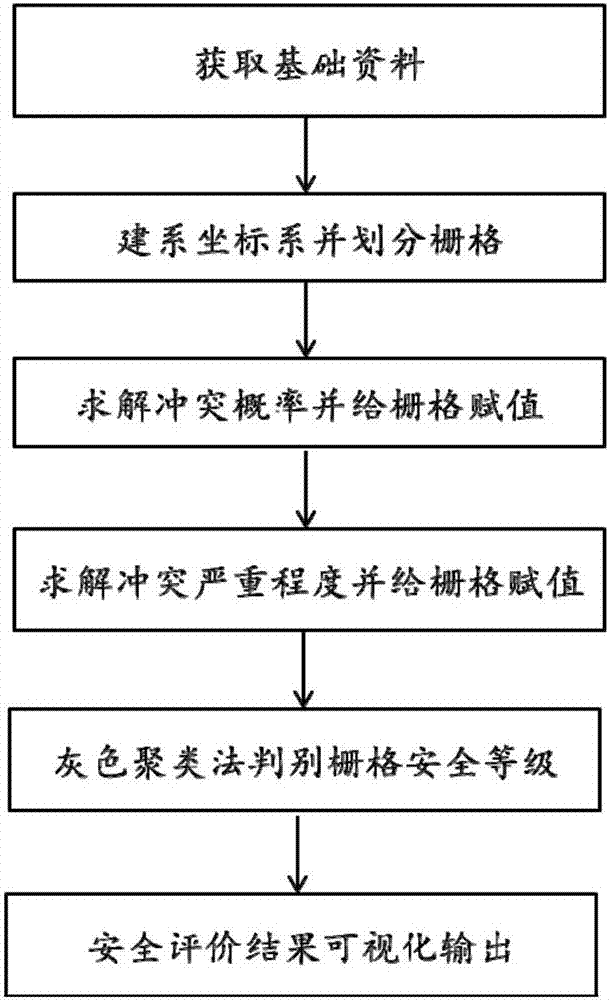

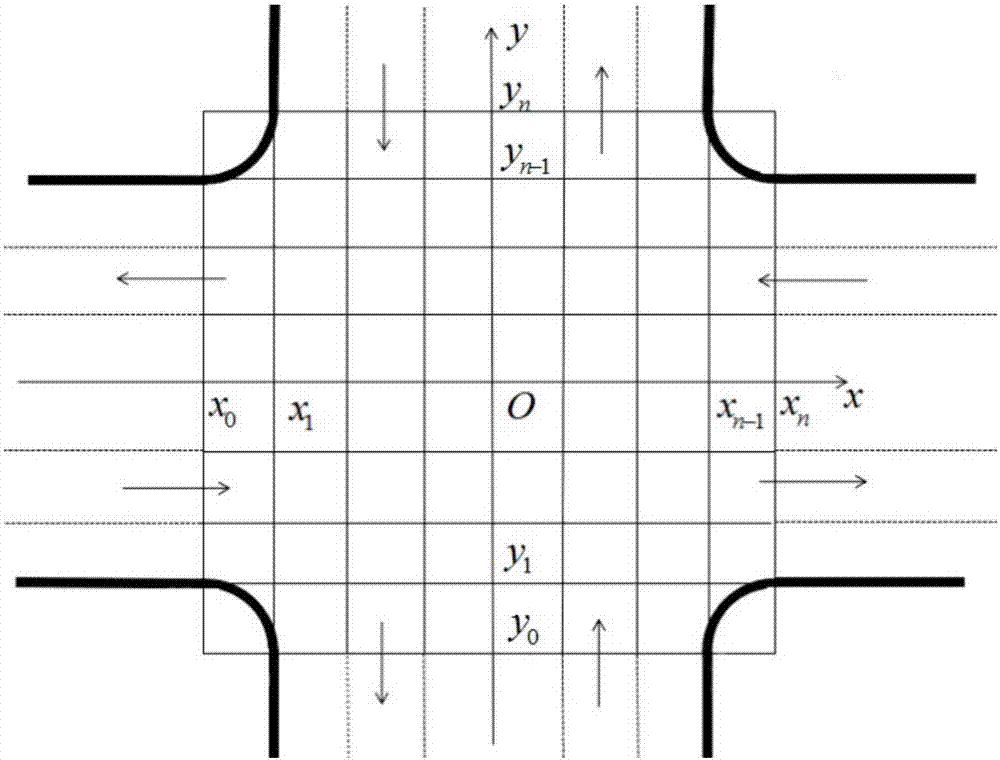

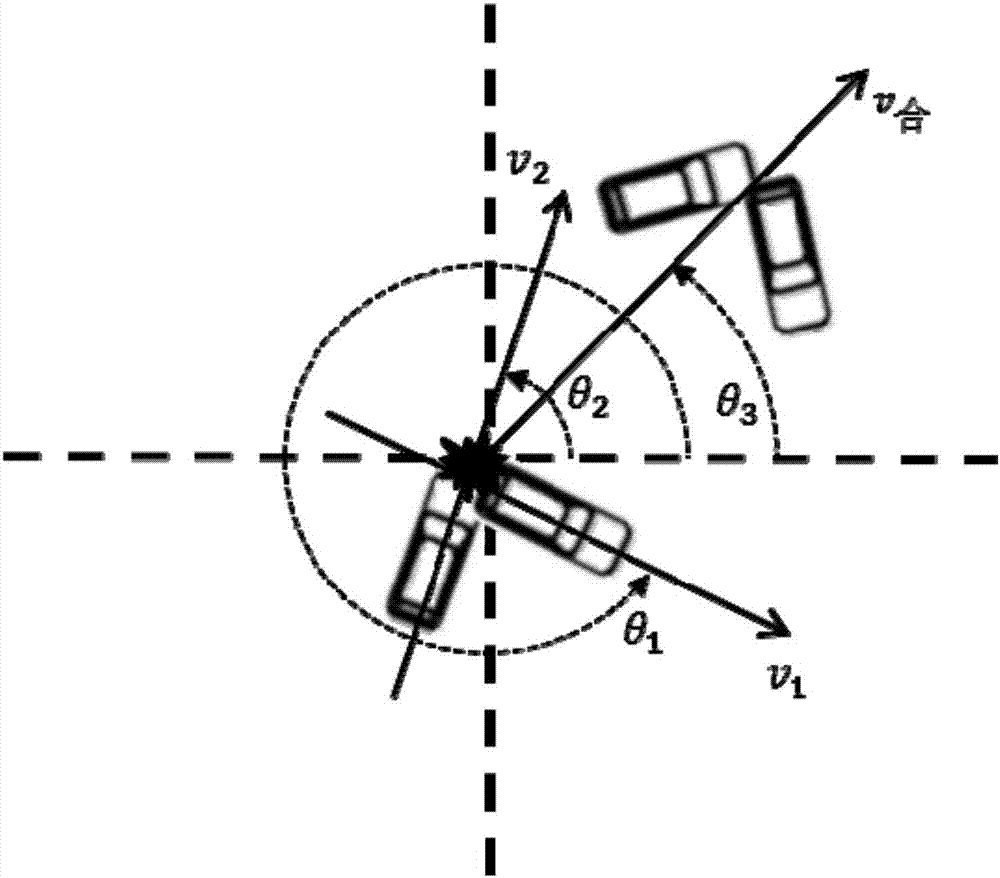

A traffic safety evaluation method for unsignalized intersections

ActiveCN105741551BImprove comprehensivenessImprove reliabilityDetection of traffic movementEvaluation resultTraffic signal

The invention discloses a method for evaluating the traffic safety of an unsignalized intersection. The method includes the steps of selecting an intersection to researched, obtaining basic data, processing basic data of the intersection, establishing a coordinate system and carrying out grid division, obtaining the conflict probability of each grid, assigning inner grids of the entire intersection to form a conflict probability matrix, obtaining the severe degree of conflict probability of each grid according to a conflict severe degree kinetic energy loss model, assigning the grids in the entire intersection, determining the safety evaluation index of each grid in the entire intersection by using a grey cluster method and taking conflict probability and conflict severe degree into consideration, assigning equivalent codes to each grid and constructing a grade code matrix, and realizing visualized output of the safety evaluation result through a programming language. Comprehensive safety evaluation index determination and visualized output of safety evaluation of the entire intersection are realized.

Owner:SOUTH CHINA UNIV OF TECH

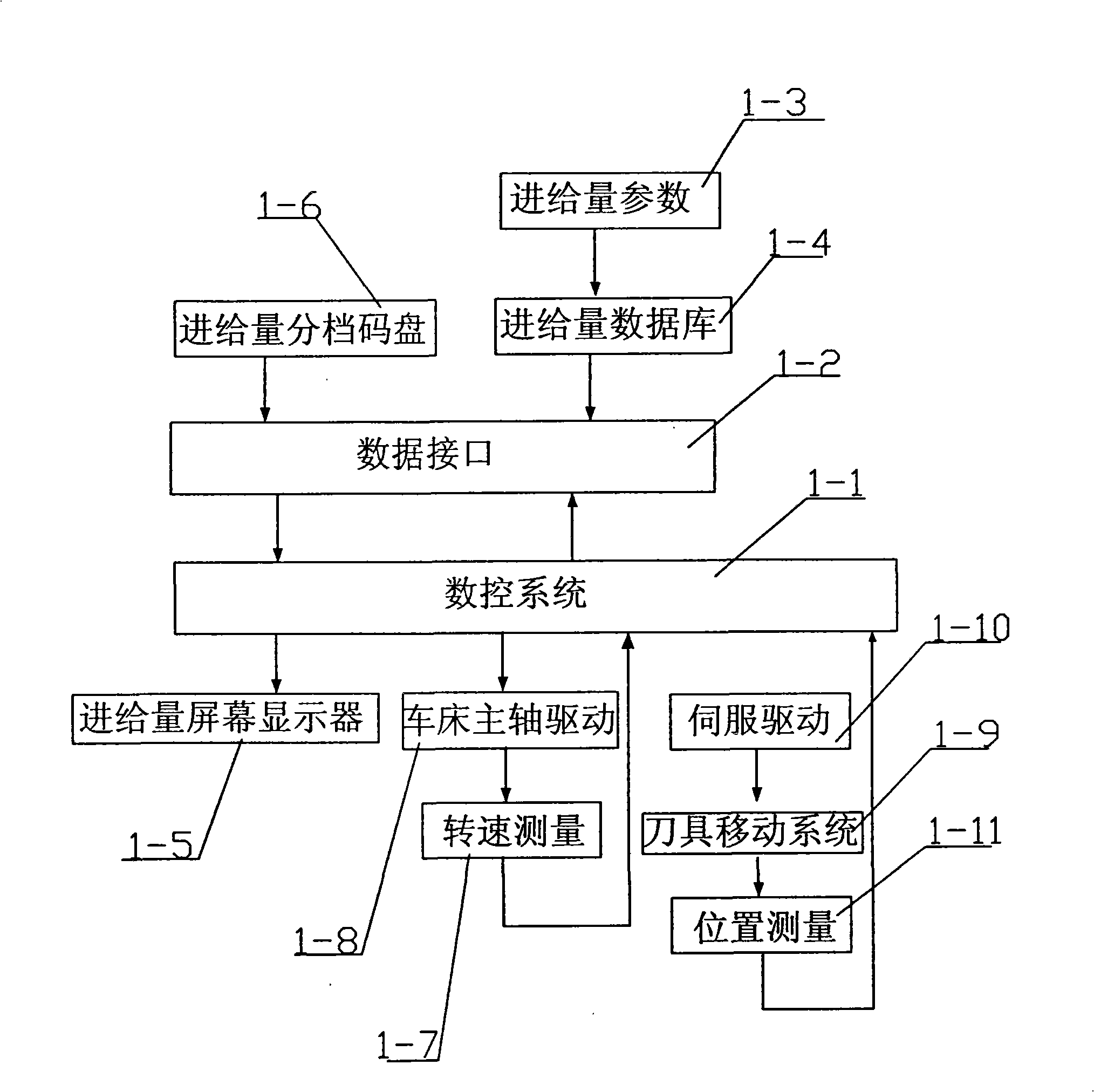

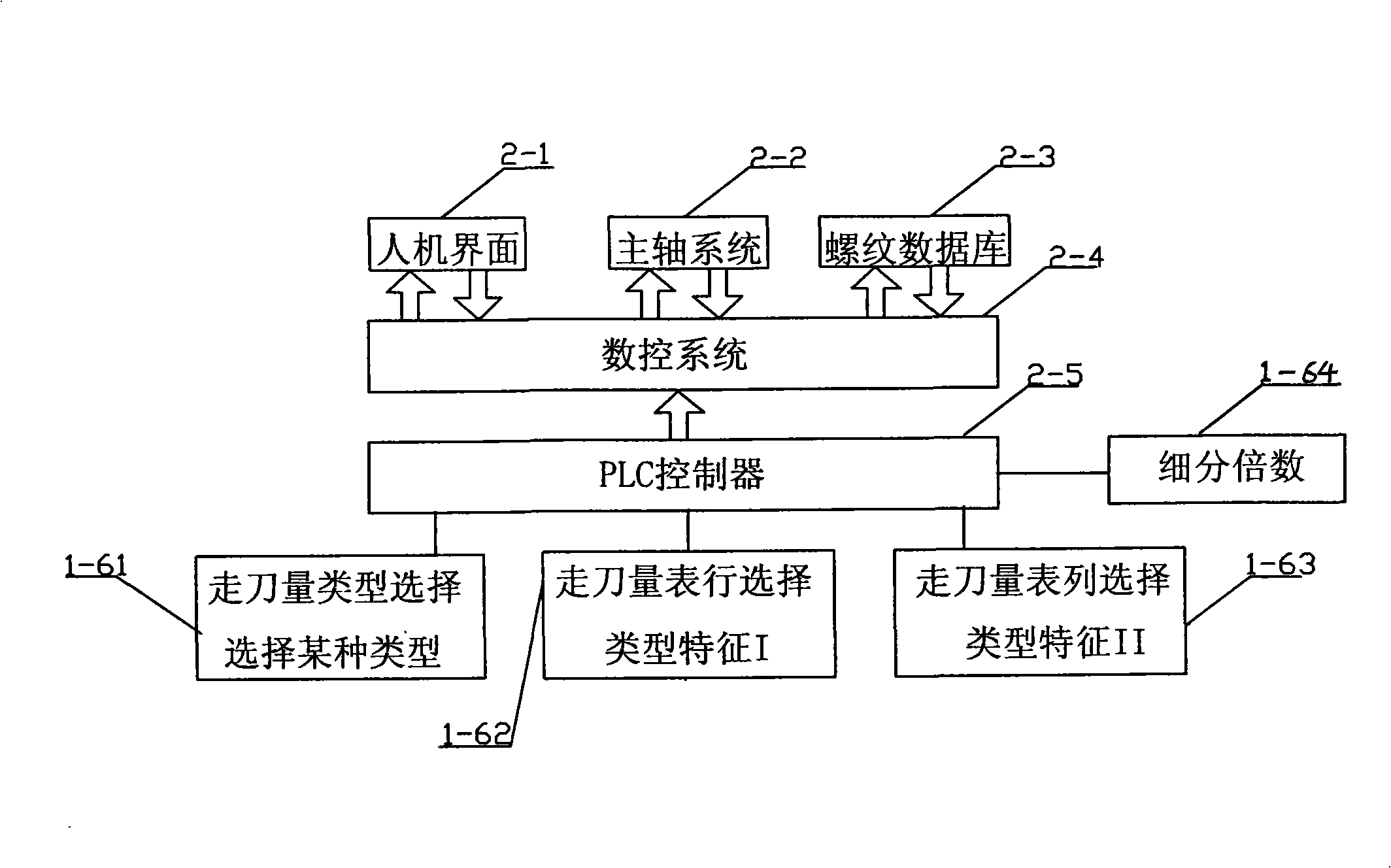

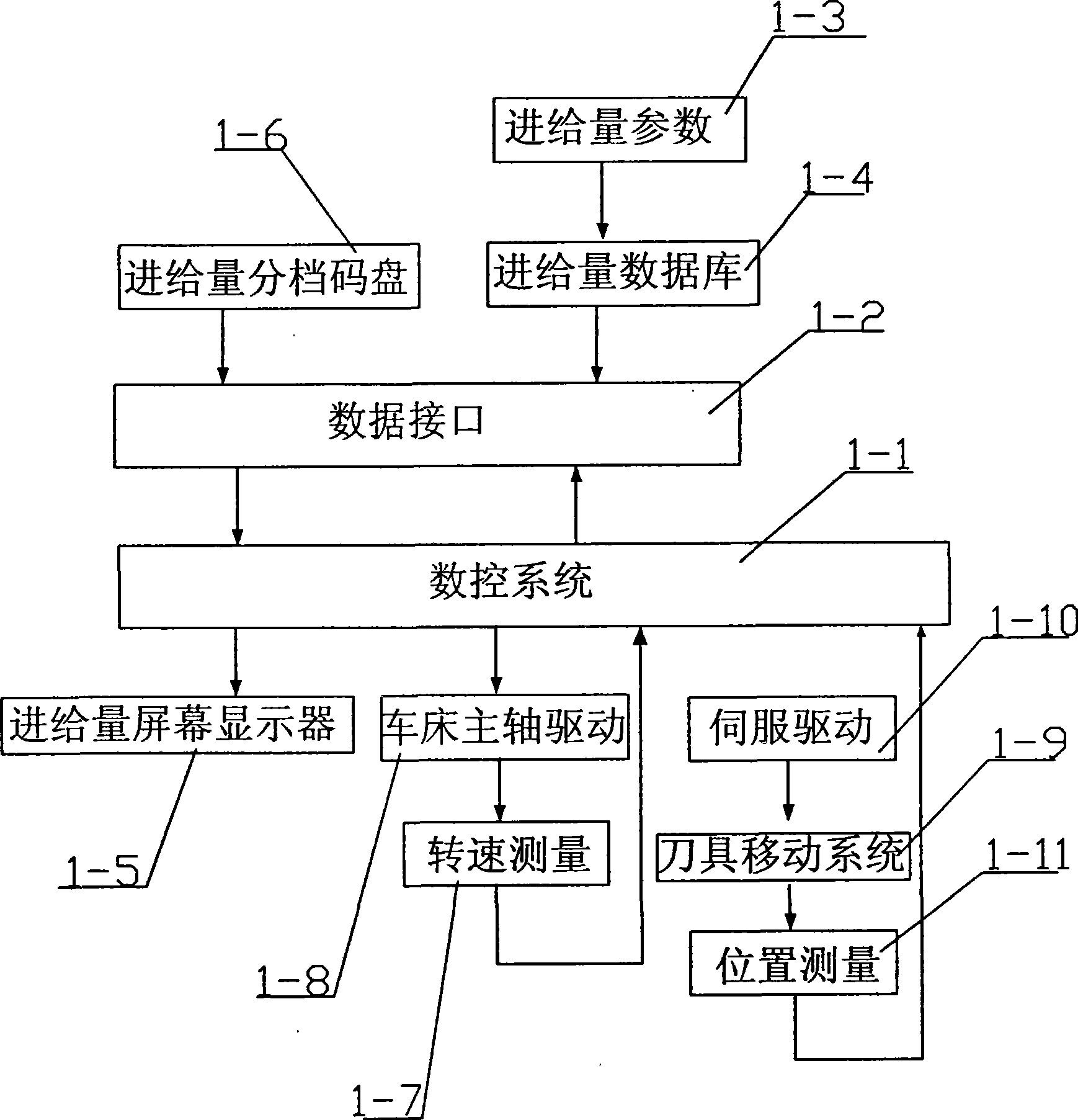

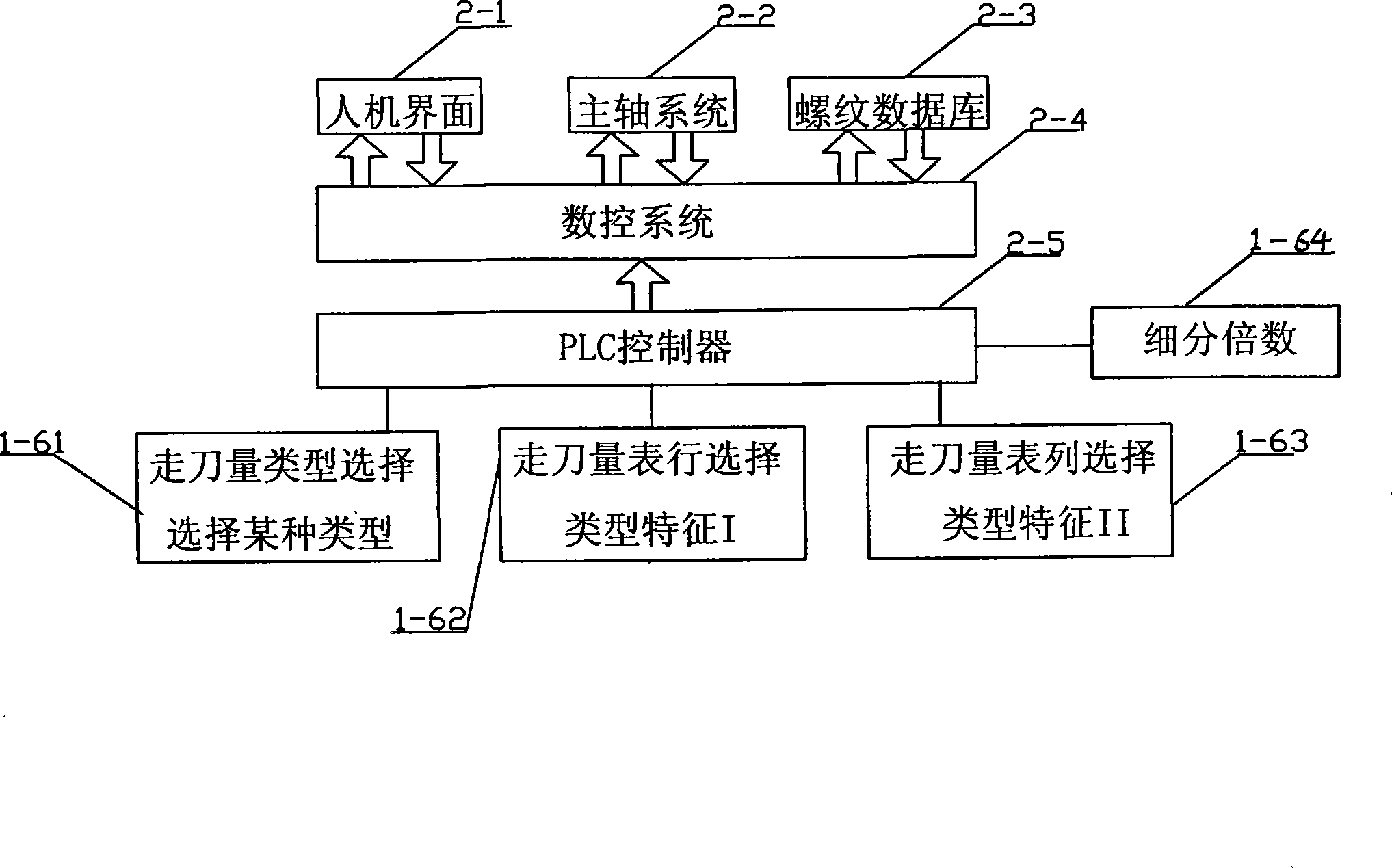

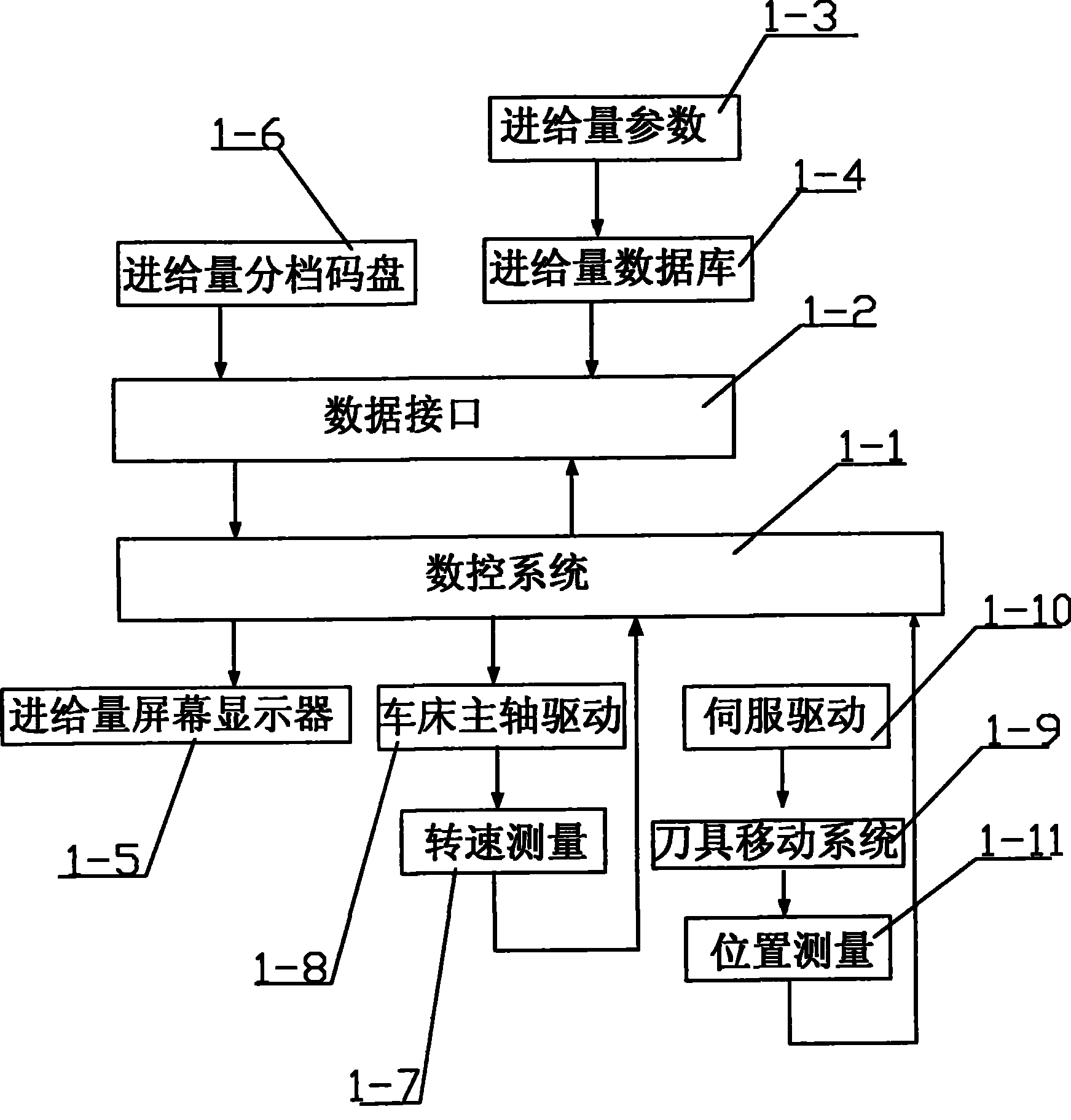

Method for setting feed amount of multi-level code disc used for NC-plain compatible machine tool with multiple operation modes

InactiveCN101344774AEasy to useHigh man-machine functionNumerical controlDisplay deviceOperation mode

The invention mainly relates to a numerical-control machine tool feed-setting method. A feed setting method using graded code discs, which is applied to NC-plain compatible machine tools of multiple operation modes, and characterized by comprising the following steps of: inputting feed parameters (1-3) of a machine tool into a feed database (1-4) and inputting the feed database (1-4) into a special NC system (1-1) of the machine tool through a data interface (1-2); displaying the feed parameter table in matrix arrangement on the monitor in real time or indicating the feed parameter list at a notable position of the machine tool; distributing each type of feed parameters into a matrix table. The machine tool is provided with an operation panel with a plurality of graded code discs (1-6) for feed parameter selection, and all graded code discs are provided with scales each of which corresponds to a feed state or a feed value. A feed is selected after rotating a selected graded code disc (1-6), the feed state or feed value is input into the special NC system (1-1) of the machine tool through the data interface (1-2); after the special NC system of the machine tool selects the corresponding feed state or feed parameter from the feed database (1-4), and the machine tool carries out processing according to the selected feed mode and parameter.

Owner:TIANSHUI SPARK MACHINE TOOL

Application software scoring method and system

The invention discloses a grading method for an application software, which comprises the following steps: obtaining: obtaining a to-be-graded application software; unpacking and analyzing: decomposing the application software to obtain a decomposing result containing an executable file part and a data file part; grading guiding: generating a grading code related to the result according to the decomposing result; and packaging: re-packaging the decomposing result and the grading code to obtain an application software with a grading function and marking the application software as the re-packaged application software, wherein when the re-packaged application software is used by a user, the grading code is executed, so as to guide the user to grade the to-be-graded application software. According to the grading method and the system for the application software, an added grading guiding program is combined with the application software, so that the grading guiding program runs at a specific moment when the application is executed by the user on an intelligent terminal, so as to guide the user to a mobile application market for grading the application.

Owner:BEIJING FEILIU JIUTIAN TECH CO LTD

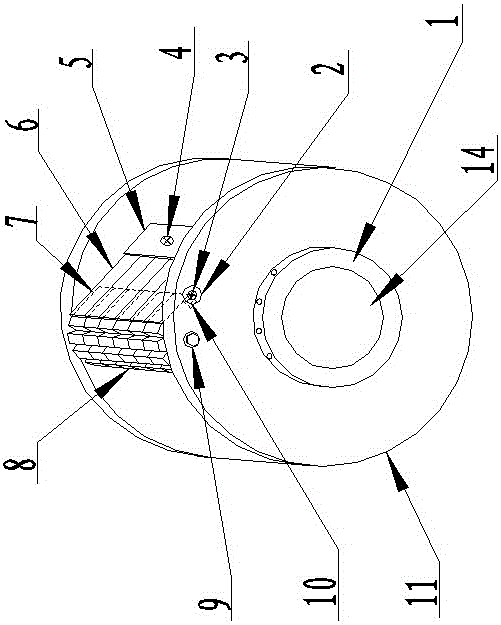

Double eccentric wheel type steel seal dialing device

Owner:CHINA TOBACCO HENAN IND

Chinese phonetic computer input method

InactiveCN1560721AIn line with language thinking habitsImprove regularityInput/output processes for data processingSyllableStandard Chinese

The invention relates to Chinese character computer input method, especially relates to input method with Chinese character text syllable. The invention is based on the current standard Chinese character syllable, each syllable of Chinese character is divided into two parts of level tone and narrow tone, the level tone includes negative level tone and positive level tone, the narrow tone includes up tone, and falling tone; the initial consonant is the same to the Chinese character syllable; the simple or compound vowel is divided into level tone and narrow tone, which is inputted into computer with different letter type. The input method in the invention has characters of strong code rule principle, simple, easy to be learned, convenient, especially it is the first grade code rule of Chinese character text code, it can be mastered in a short time.

Owner:芦爱军

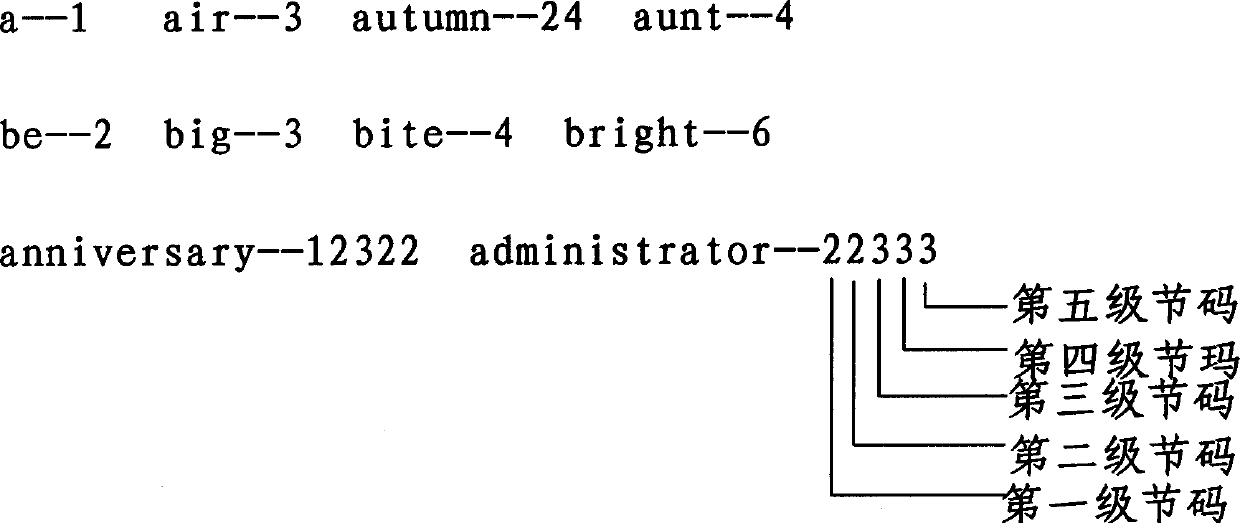

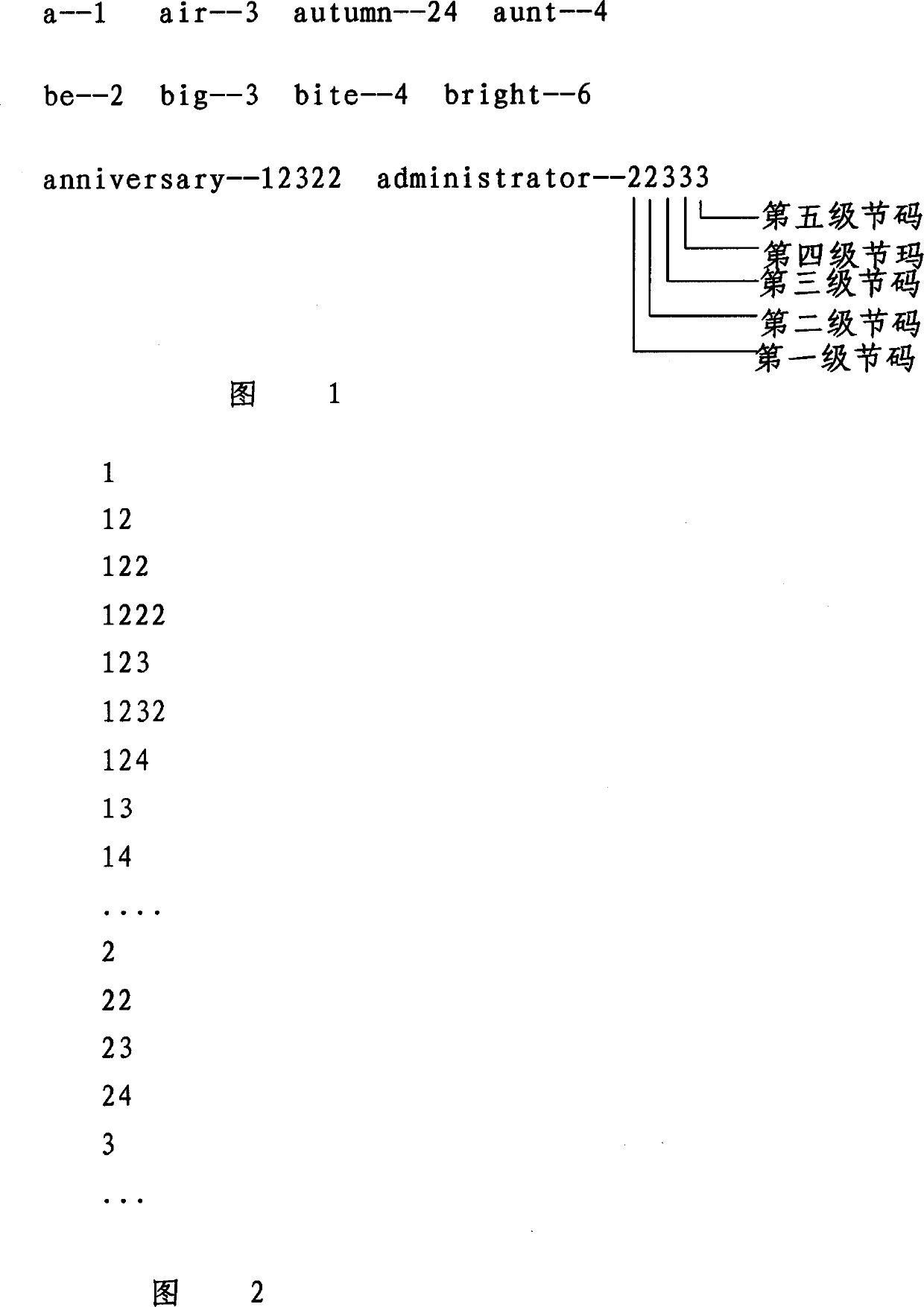

English section code searching method

InactiveCN1803468AStrengthen the sense of syllableEasy to rememberToysFiling appliancesSyllableElectronic dictionary

The invention discloses an English code index method in the dictionary, which comprises the following steps: a. constituting code according to letter quantity of each syllable in the word; b. classifying the English word into cluster according to the beginning letter; c. arranging the word according to precedence code sequence; d. adapting number in each grade code from small to big; e. arranging the word according to the vowel letter sequence when the codes are same. The invention is rapid to check to improve the index speed, which can be used in the new typed English-Chinese dictionary, electronic dictionary software and present English dictionary.

Owner:王光春

An Annotation Generation Method for Soil Spatial Data Mapping

InactiveCN104021211BAutomate processingSolve the problem of step judgmentGeographical information databasesSpecial data processing applicationsSpatial mappingTheoretical computer science

The invention discloses a method for generating notes of a soil spatial data graph. The method includes the first step of generating a structural table, a grading code table and a storage path table according to a database; the second step of establishing a grading code and typeface relational table V_GrTxt; the third step of carrying out note setting and edge buffering setting on a map layer according to the structural table, generating a table Vlay and selecting grading code fields needing counting to count grading codes; the fourth step of merging the grading code table with the table Vlay and the table V_GrTxt and generating a grading code table V2_Gr, wherein the grading code table V2_Gr is provided with a GrOff field determining whether notes are generated or not and a Curve field setting the arrangement direction in which the notes are generated; the fifth step of screening the grading codes in the table V2_Gr according to a statistic result and determining whether the grading codes generate the notes or not; the sixth step of merging distinguish results, generating a grading code table V4_Leg of the notes and generating a note layer according to the Curve field and the table V_GrTxt. The method achieves automatic receding and generation of the notes.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

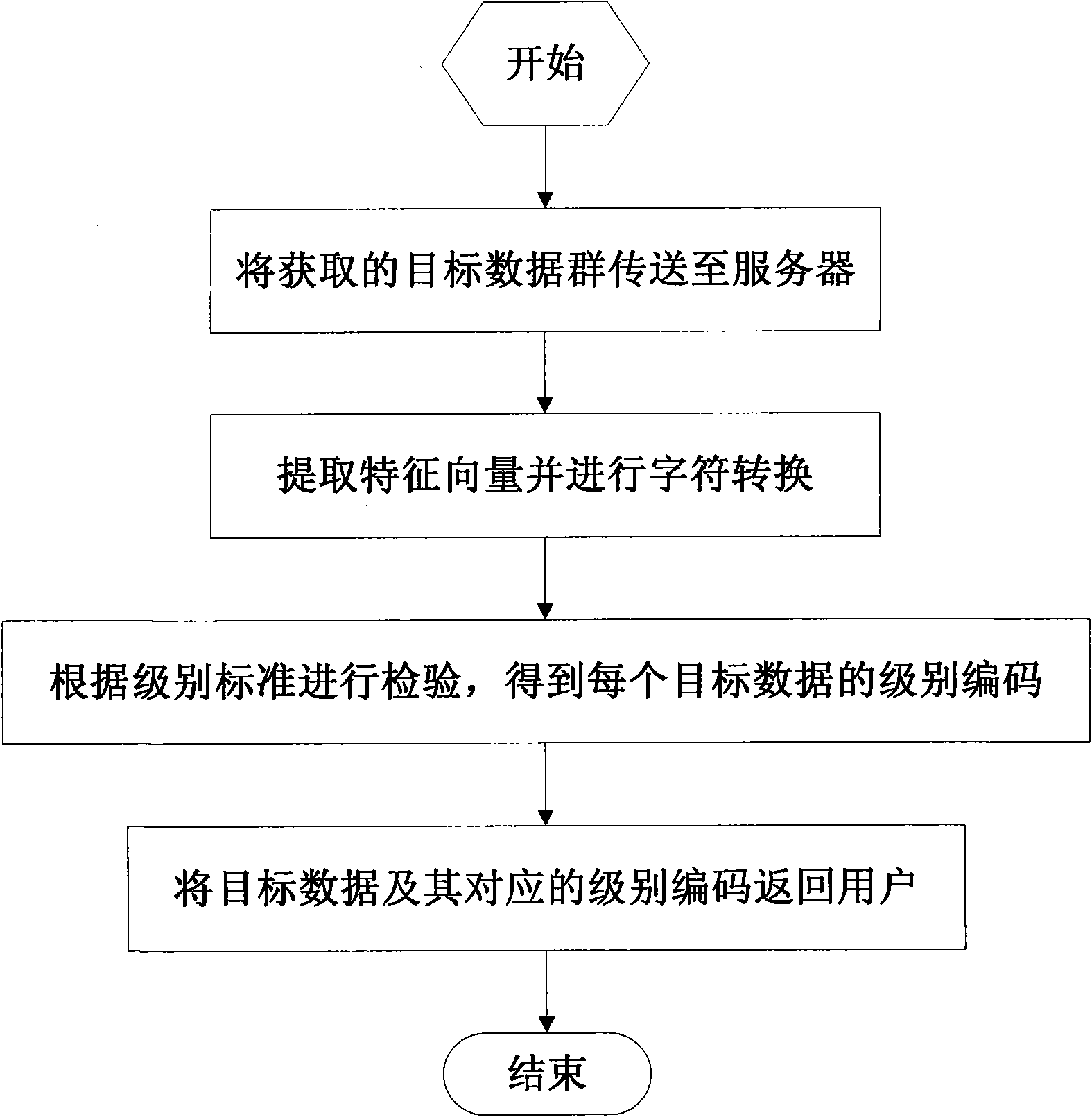

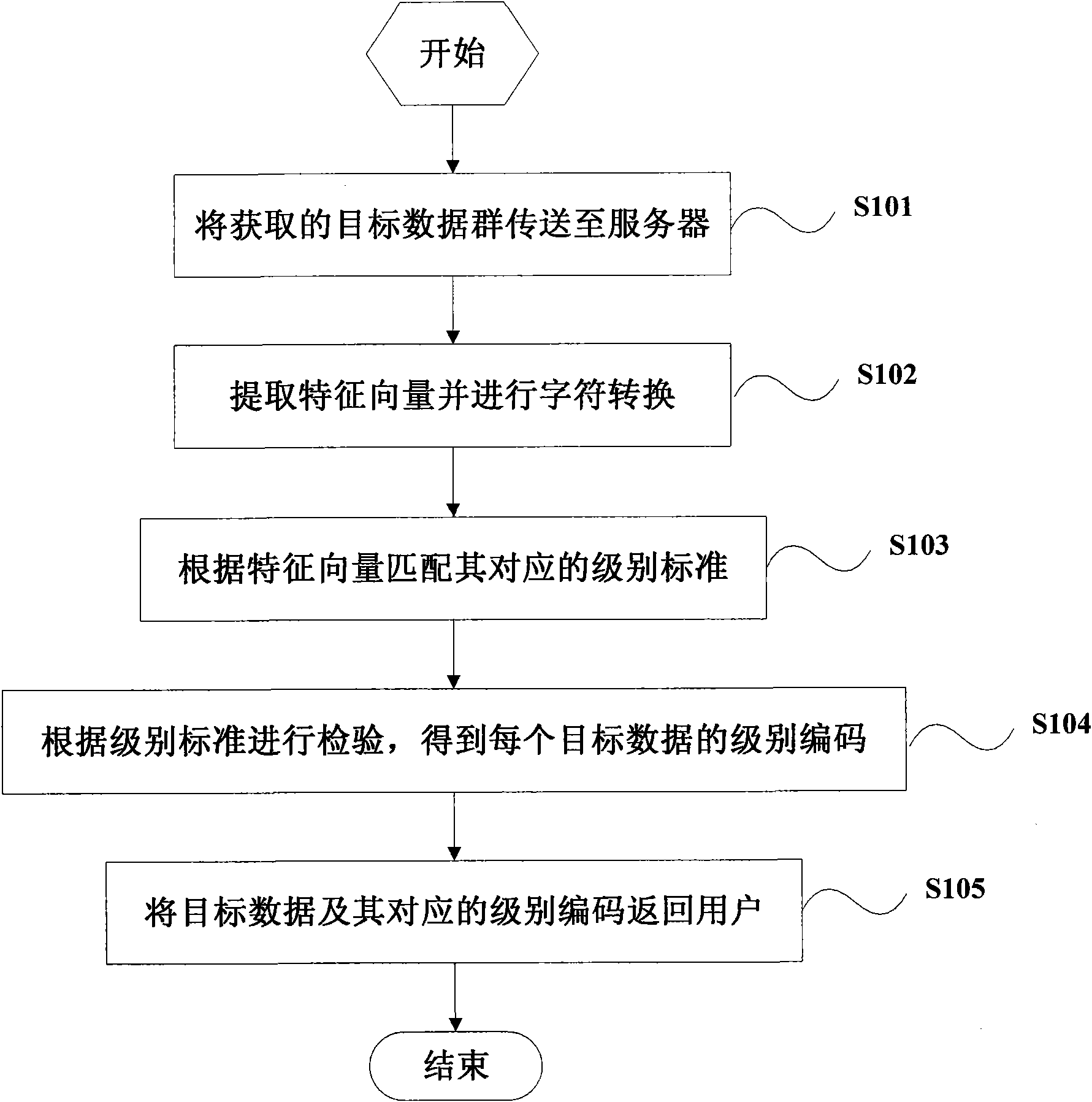

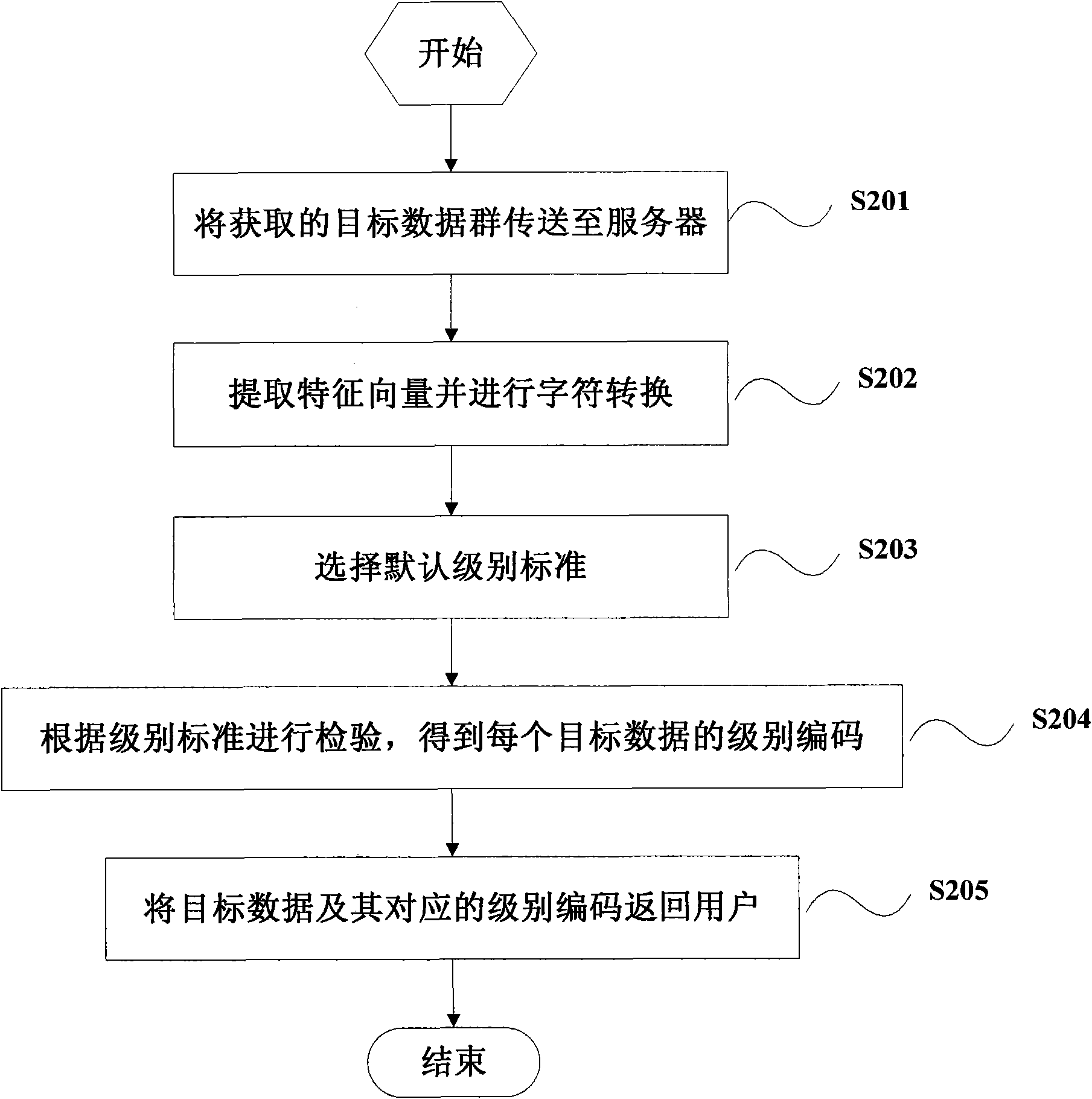

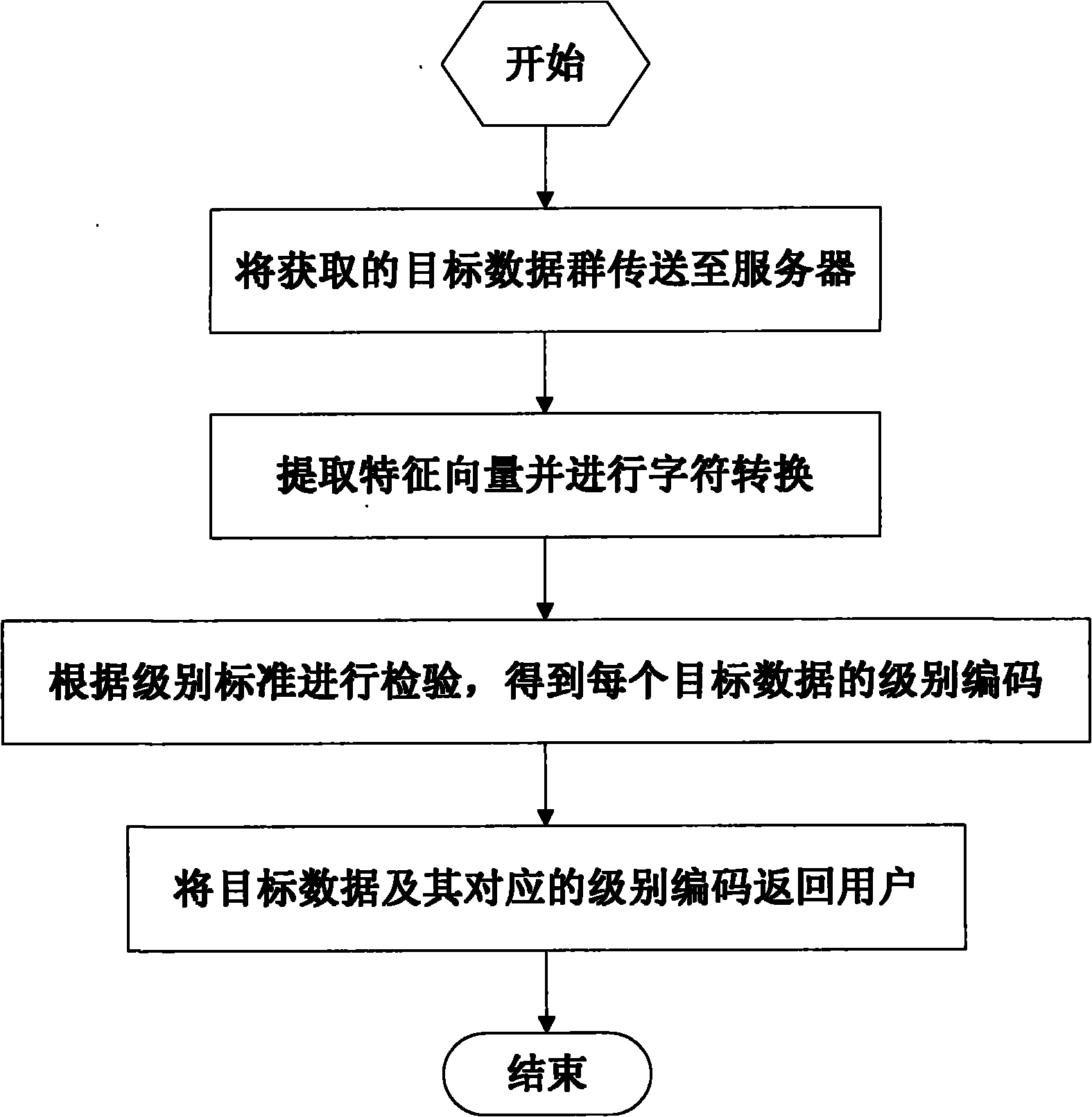

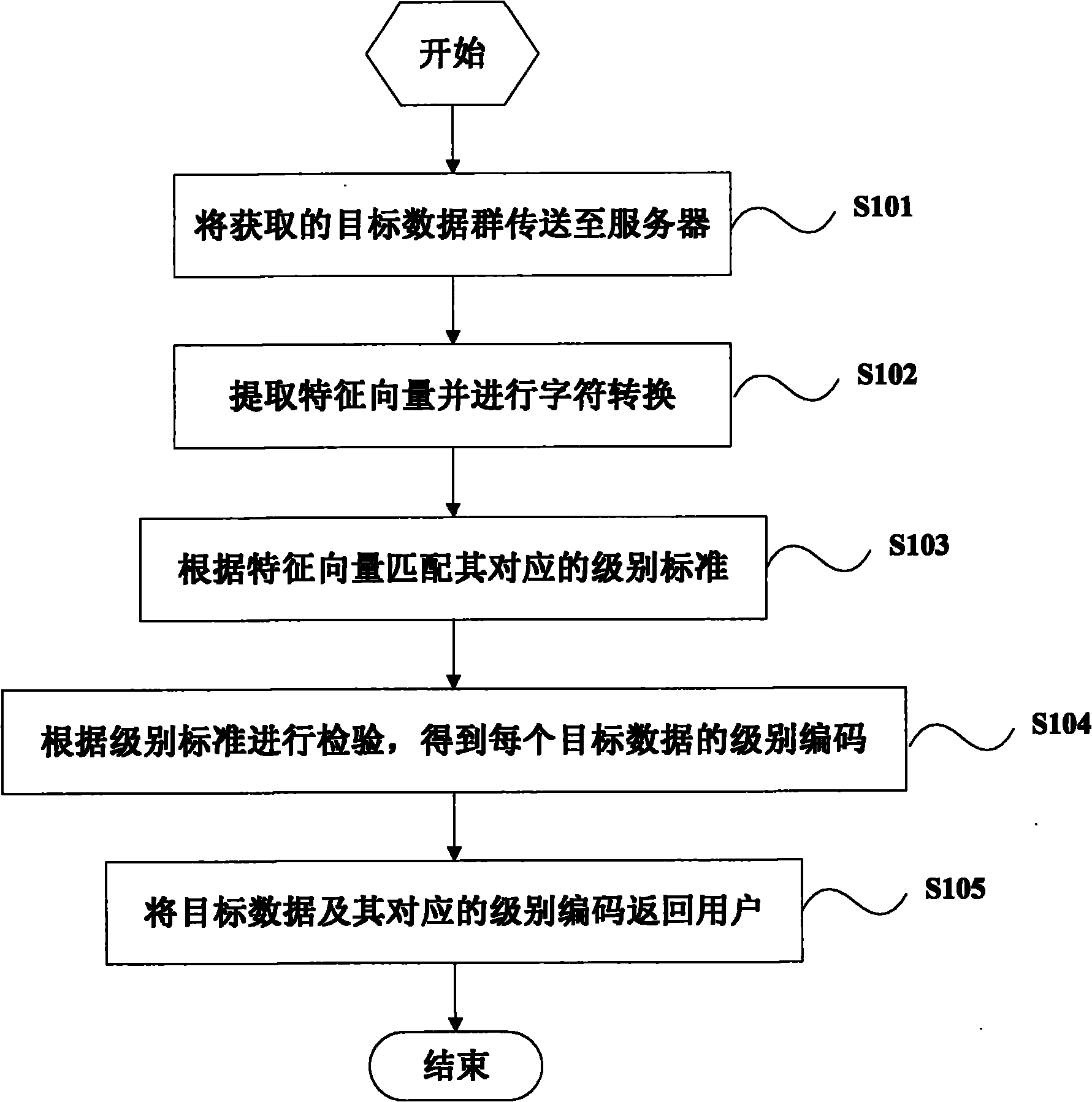

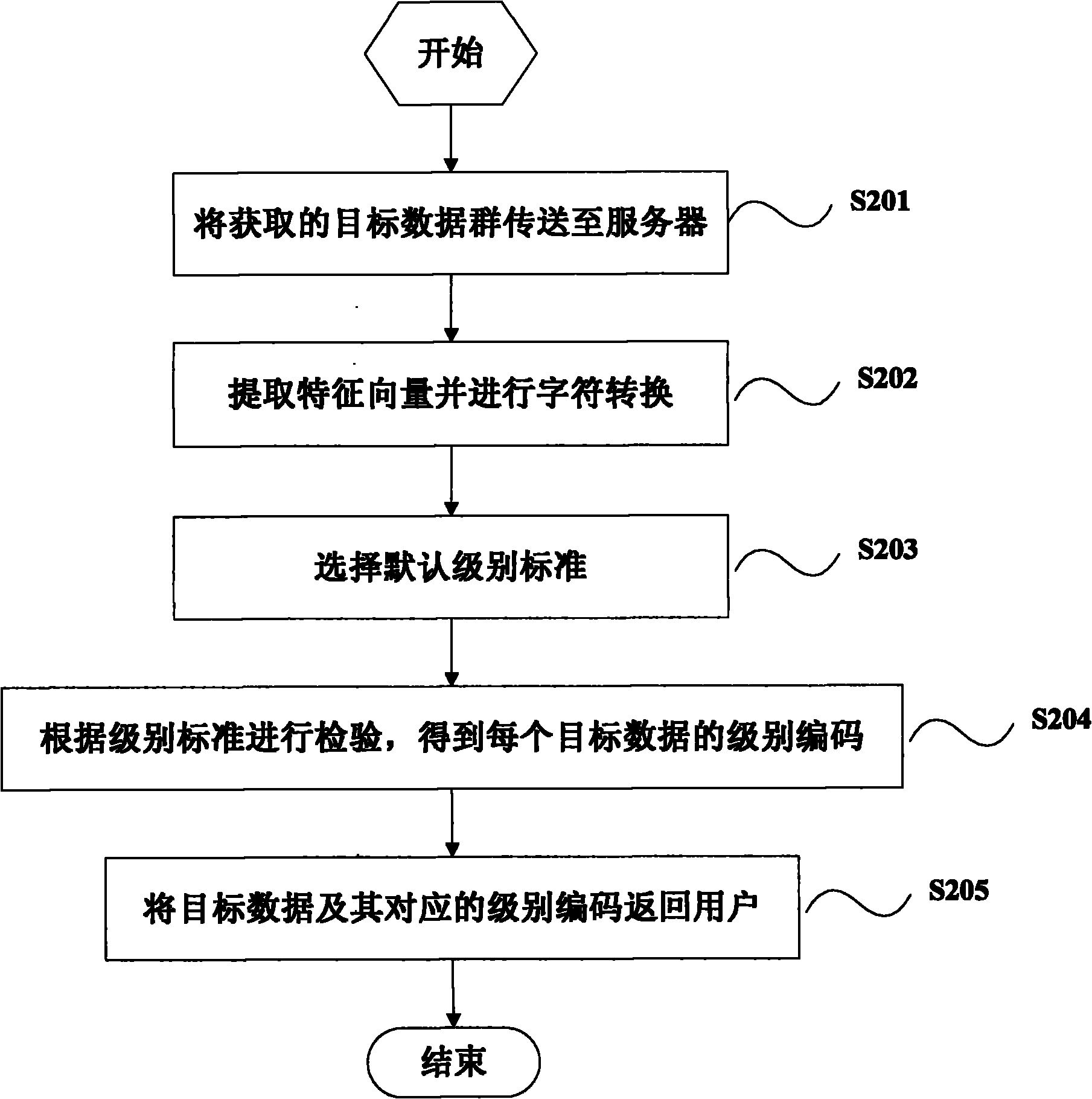

Data quality grade judging method

ActiveCN102609418BFast inspectionImprove accuracySpecial data processing applicationsFeature vectorData quality

The invention provides a data quality grade judging method, which comprises the following steps: transmitting an obtained objective data group to a server; extracting a characteristic vector of each objective data in the objective data group and performing the character conversion on the characteristic vector so as to obtain character set data corresponding to each characteristic vector; examining the character set data according to a grade standard stored in the server so as to obtain a quality grade code of each characteristic vector; and feeding back each objective data and the corresponding quality grade code to a user. According to the method, the quality of the objective data group can be examined by the grade standard stored in the server, so that the quality grade code corresponding to the objective data group is obtained and is fed back to the user; the method is rapid in examination speed and high in accuracy; and the user can carry out a corresponding processing according to each objective data and the corresponding quality grade code.

Owner:北京世纪读秀技术有限公司

Data quality grade judging method

ActiveCN102609418AFast inspectionImprove accuracySpecial data processing applicationsFeature vectorData quality

The invention provides a data quality grade judging method, which comprises the following steps: transmitting an obtained objective data group to a server; extracting a characteristic vector of each objective data in the objective data group and performing the character conversion on the characteristic vector so as to obtain character set data corresponding to each characteristic vector; examining the character set data according to a grade standard stored in the server so as to obtain a quality grade code of each characteristic vector; and feeding back each objective data and the corresponding quality grade code to a user. According to the method, the quality of the objective data group can be examined by the grade standard stored in the server, so that the quality grade code corresponding to the objective data group is obtained and is fed back to the user; the method is rapid in examination speed and high in accuracy; and the user can carry out a corresponding processing according to each objective data and the corresponding quality grade code.

Owner:北京世纪读秀技术有限公司

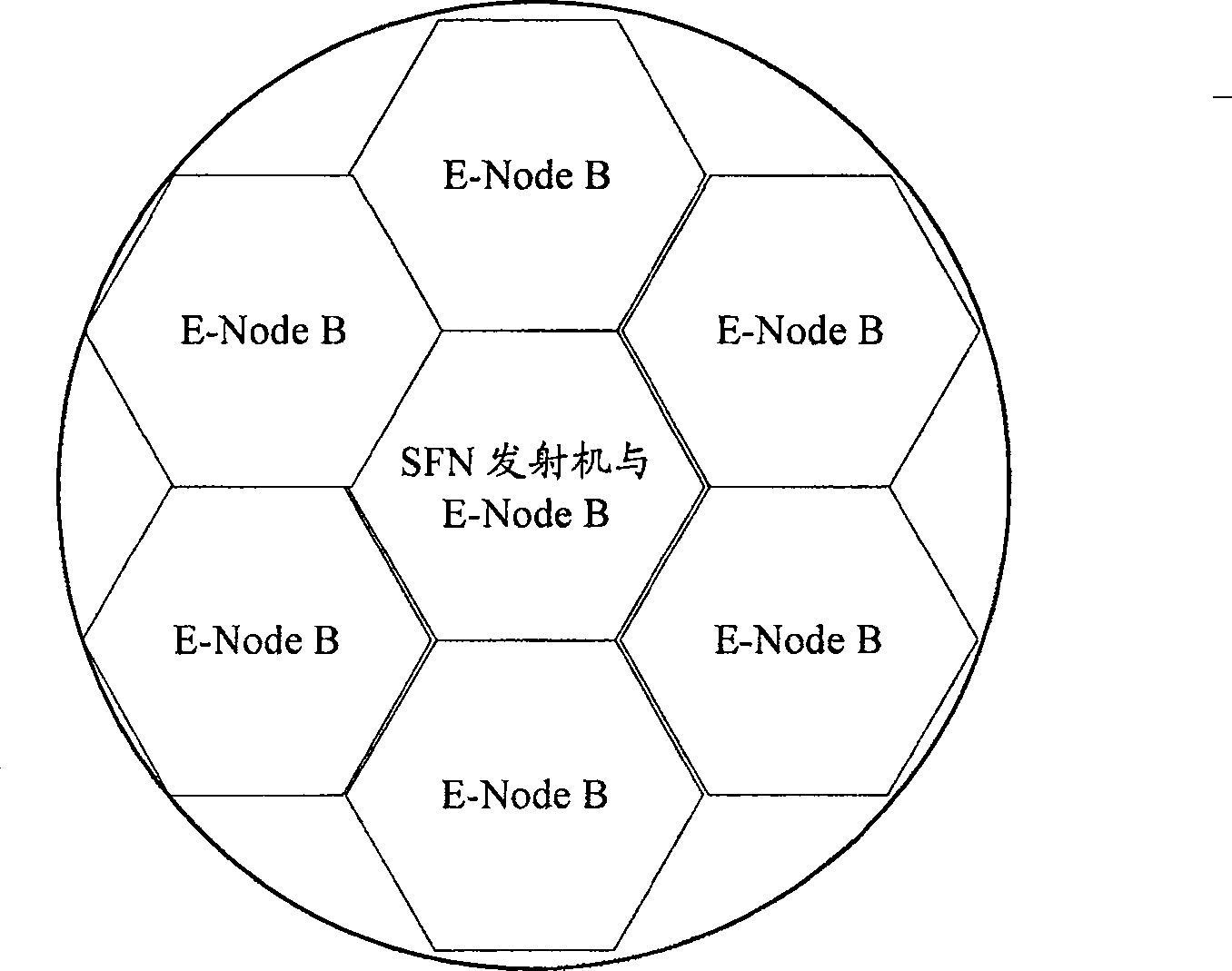

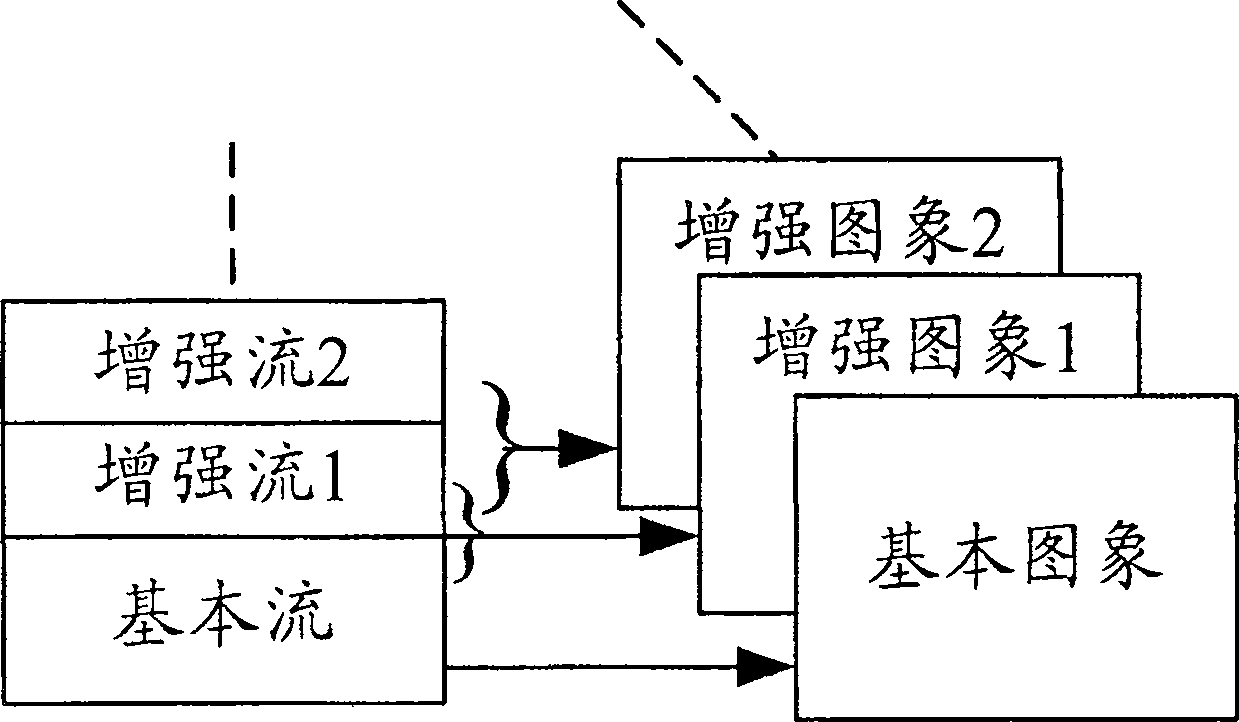

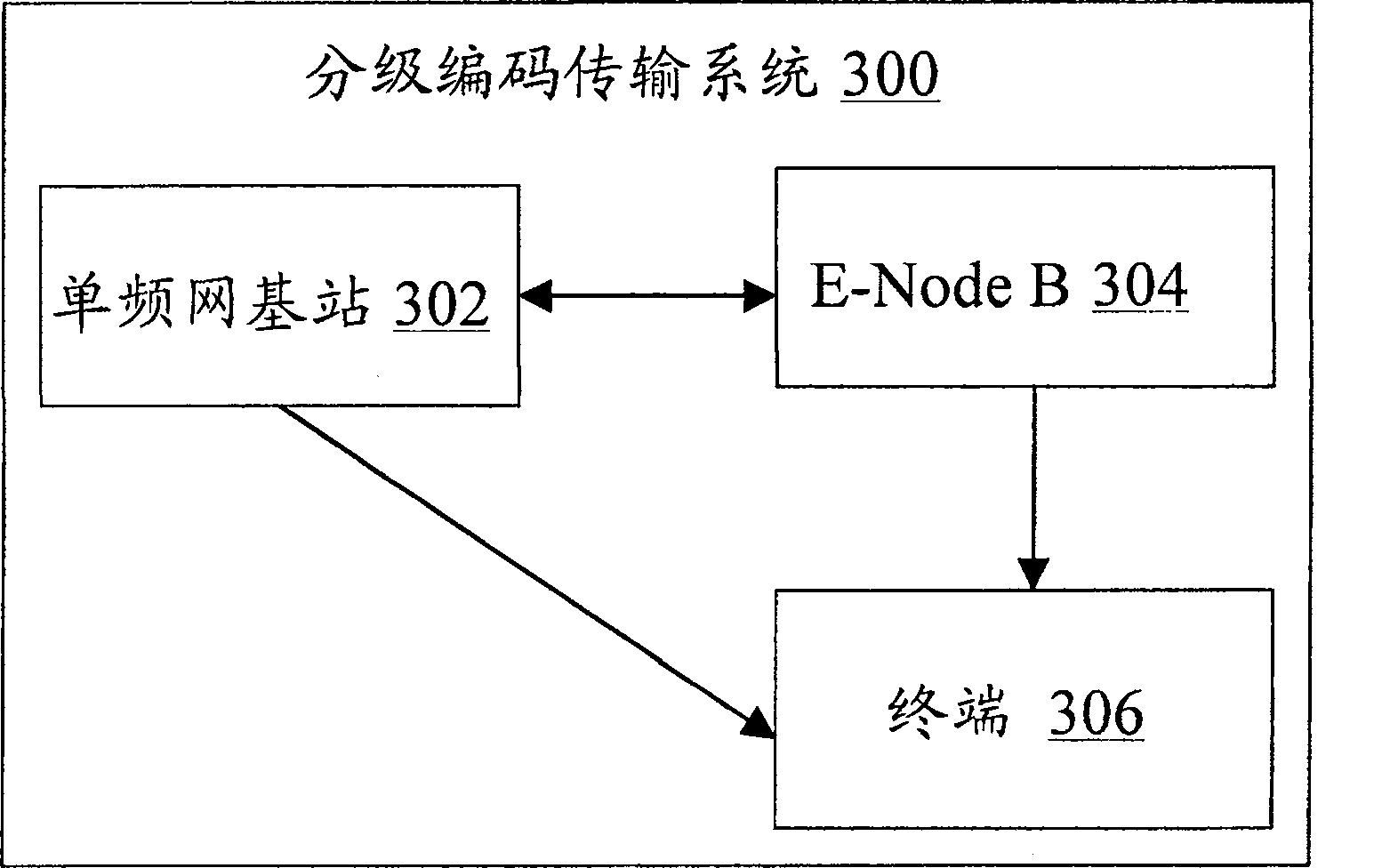

Grading code transmission system for single frequency net

InactiveCN100502533CImprove business qualityStable and balanced service qualityBroadcast service distributionRadio/inductive link selection arrangementsClosed loopComputer science

The invention comprises: single frequency network base station used for sending MBMS service data; E-Node B used for receiving MBMS service data, and replaying the MBMS service data in its transmission time slot; and terminal used for receiving MBMS service data from the single frequency network base station and / or E-Node B. The invention can remove the possibility of interference and system closed-loop oscillatory.

Owner:ZTE CORP

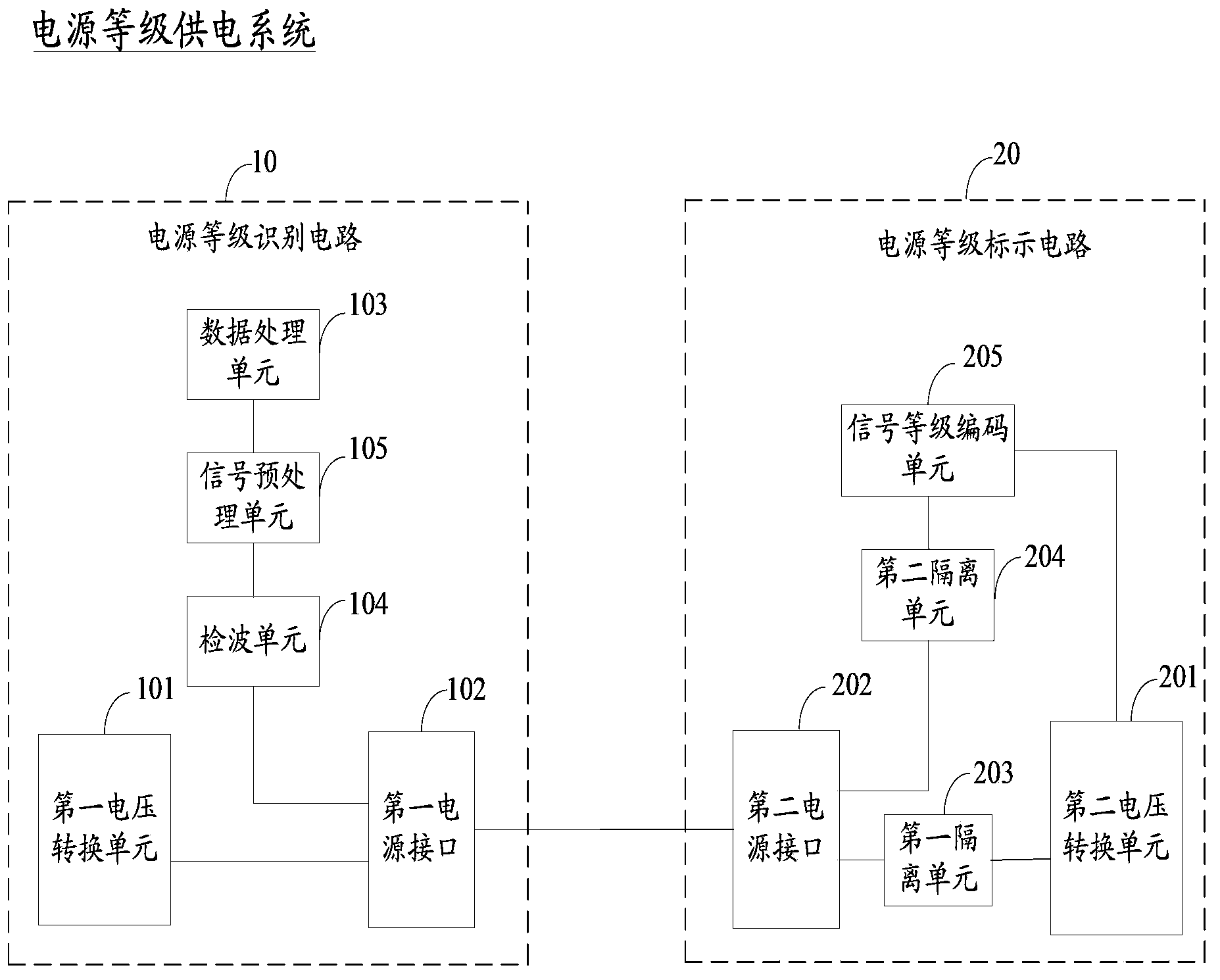

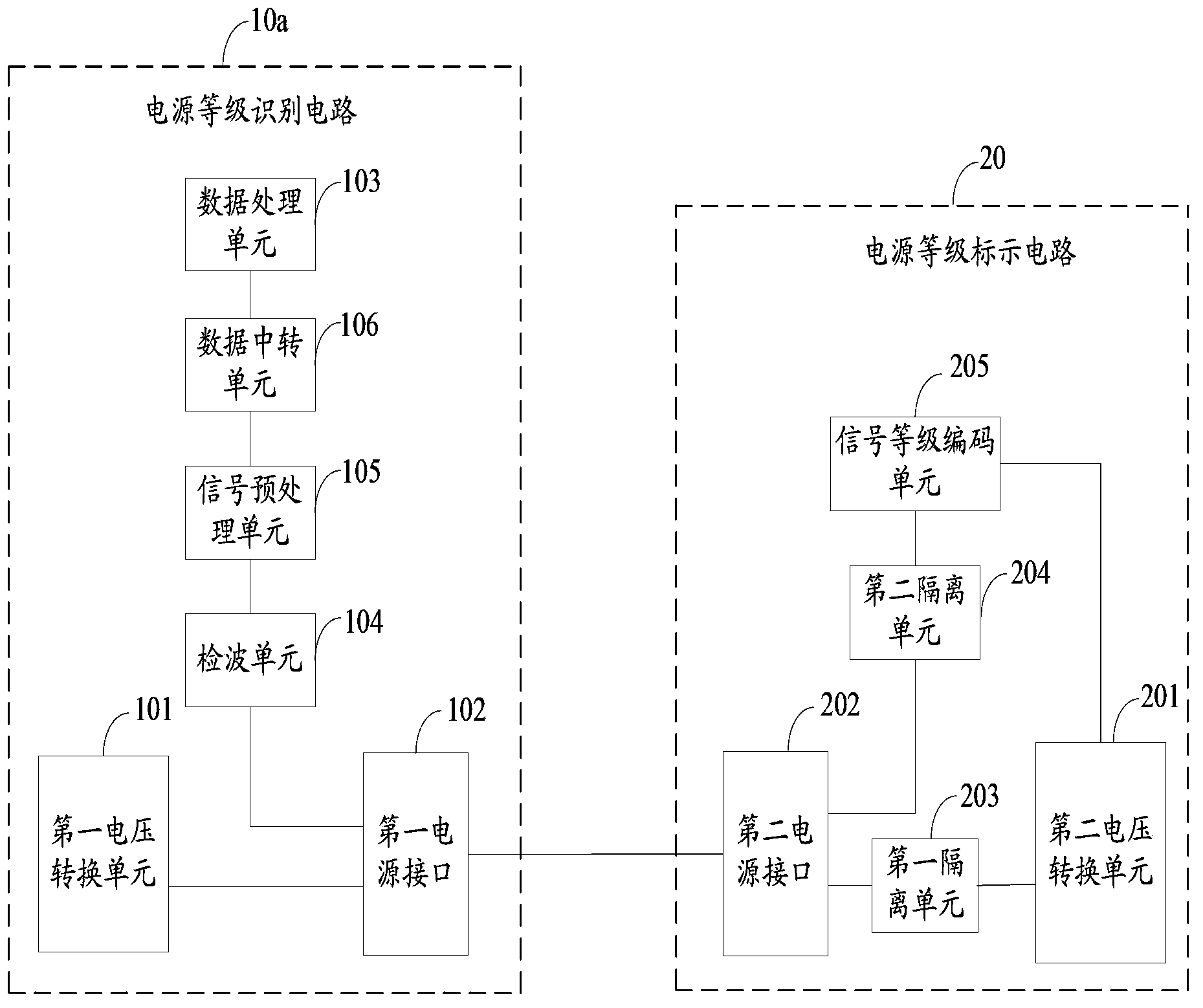

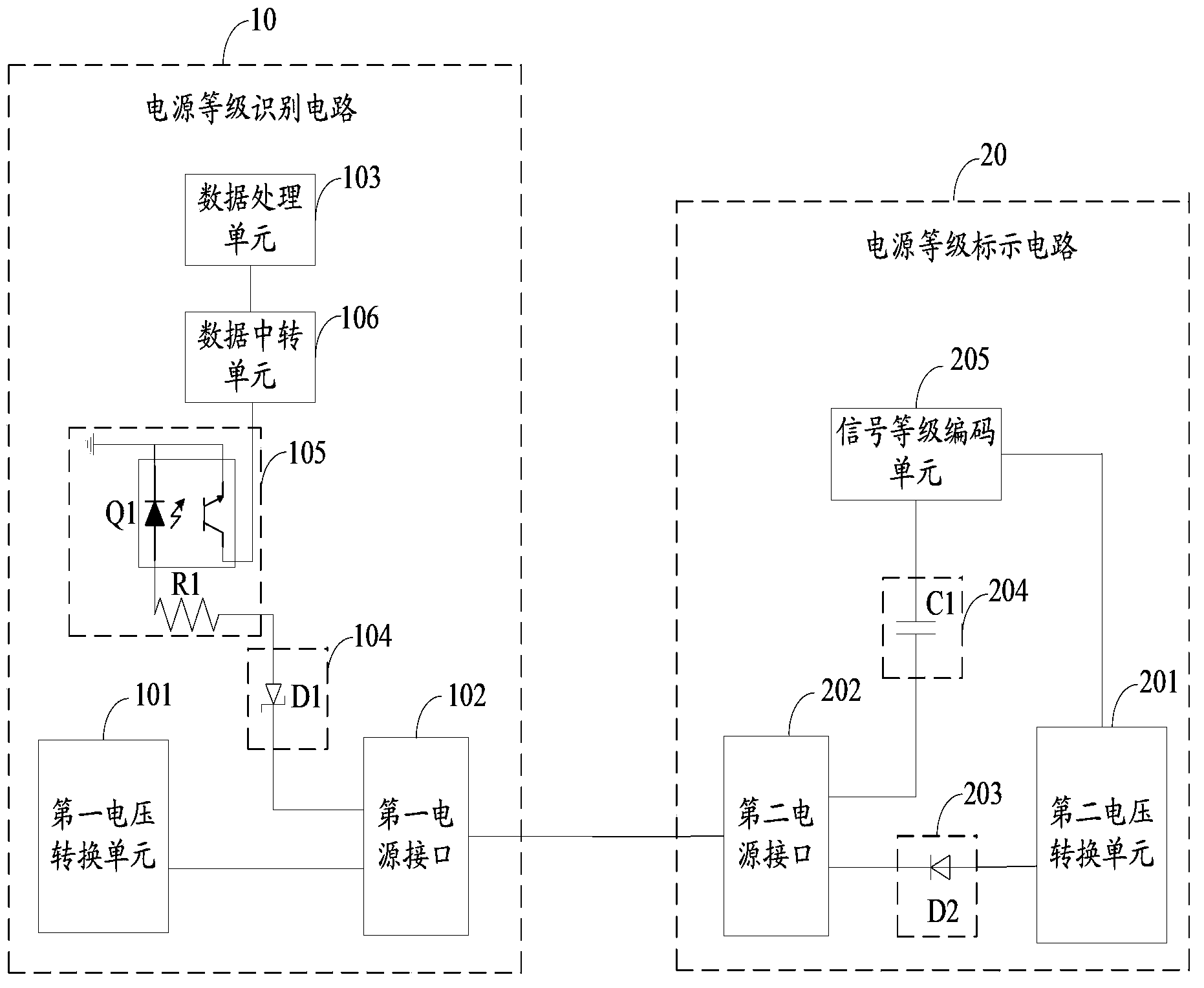

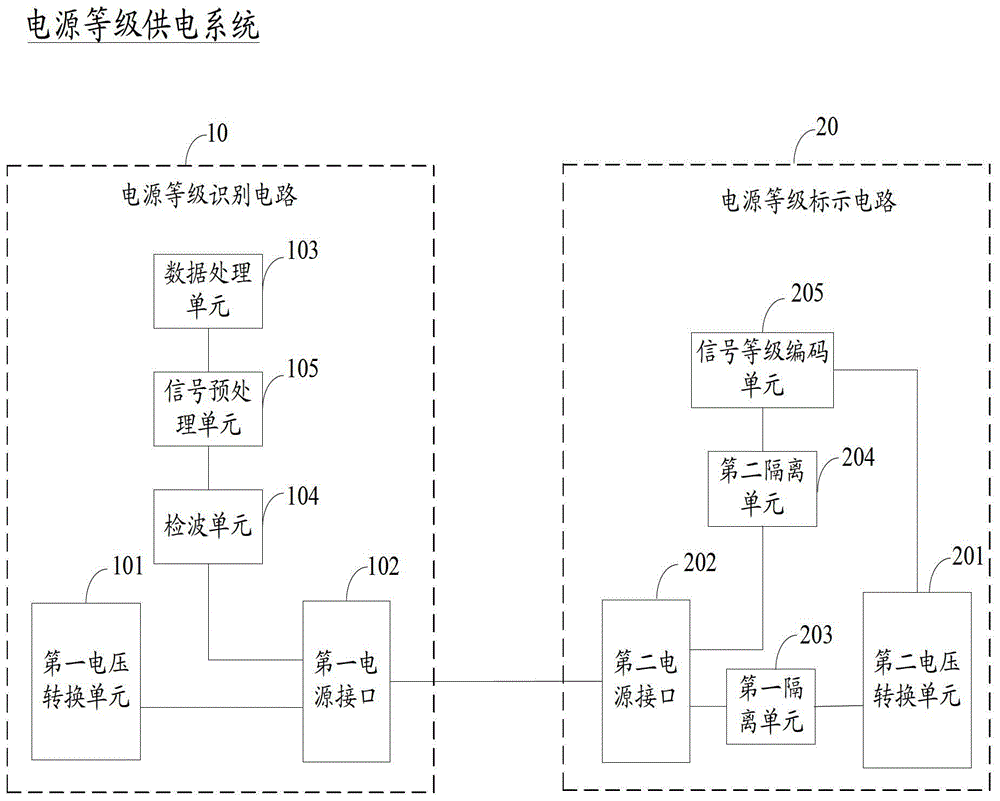

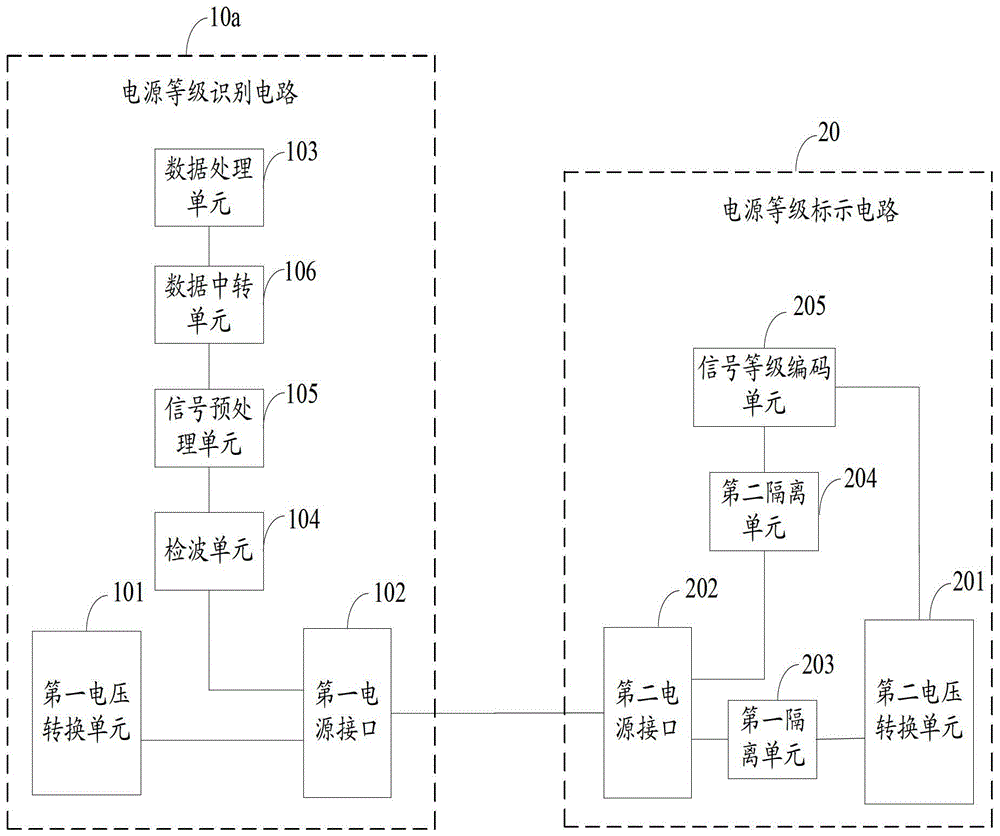

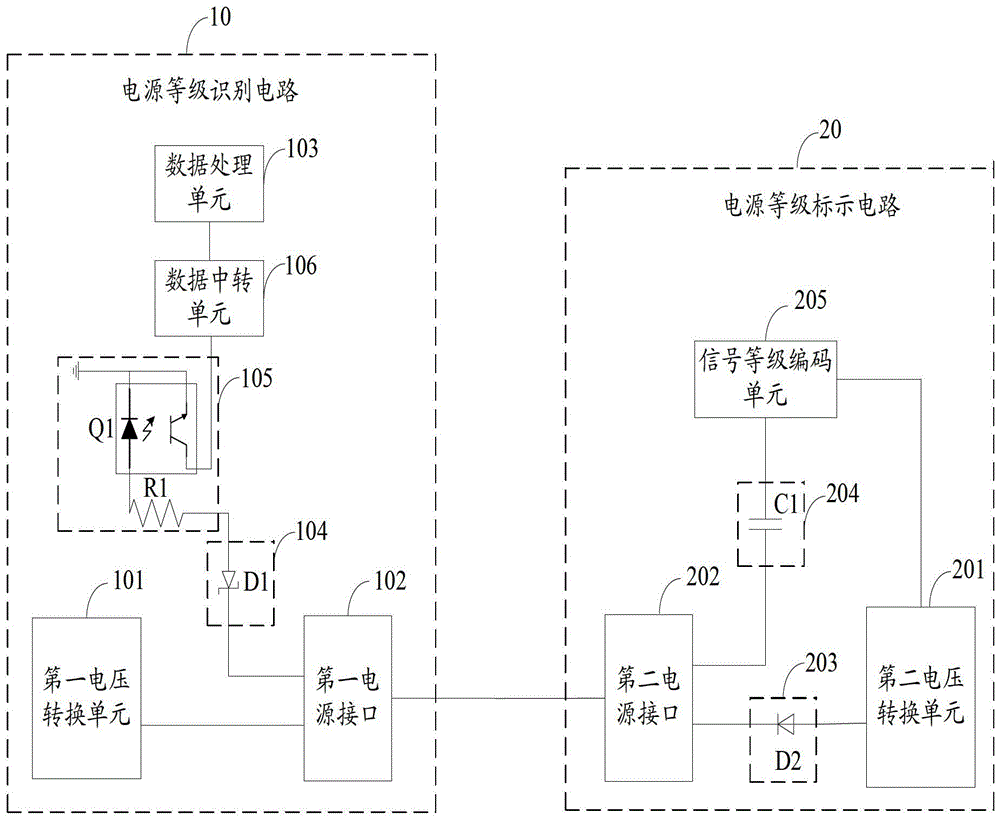

Power source grade recognition circuit, power source grade marking circuit and power source grade power supply system

A power source grade recognition circuit comprises a voltage conversion unit, a data processing unit, a first power interface, a detection unit and a signal preprocessing unit, wherein the first power interface is used for receiving power signals and power grade coded signals, the detection unit is used for filtering out the power signals in the first power interface, the signal preprocessing unit is used for shaping waves of the power grade coded signals, and the data processing unit is used for recognizing the signal grades of the shaped power grade coded signals. The invention further provides a power source grade marking circuit and a power source grade power supply system. The power source grade recognition circuit, the power source grade marking circuit and the power source grade power supply system transmit power grade information to a terminal device through the power interface, the purpose that the terminal device automatically recognizes the received power signals and carries out switching between corresponding modes is achieved, and damage to terminal device caused when users mix up the terminal devices is avoided.

Owner:NANNING FUGUI PRECISION IND CO LTD

Power level identification circuit, marking circuit and power level power supply system

Owner:NANNING FUGUI PRECISION IND CO LTD

Method for setting feed amount of multi-level code disc used for NC-plain compatible machine tool with multiple operation modes

InactiveCN101344774BEasy to useHigh man-machine functionNumerical controlDisplay deviceOperation mode

Owner:TIANSHUI SPARK MACHINE TOOL

Bar gauge by grading coding

InactiveCN102494669BReduce the difficulty of identificationLow barcode densityHeight/levelling measurementMeasuring instrumentParallel computing

A bar gauge by grading coding relates to the technical field of measuring instrument. According to the invention, the technical problem of high difficulty of present bar gauge identification is solved. Scale of the bar gauge provided by the invention is equally divided into a plurality of code segments. Each code segment is divided into a plurality of code words. Each code word is equally divided into D code element, A code element and B code element. The distances between centers of adjacent code elements are consistent. The D code element has a plurality of code bars, which are centrosymmetrically distributed to form a code segment counter. There is only one code bar at the center of the A code element and the B code element. The A code element and the B code element form a code word counter. The center line of the D code element is the start point of code words as well as the stop point of the front code word. There are a plurality of code bars in the D code element. Code segment counter values in the same code segment are consistent and convenient to identify. The bar gauge provided by the invention is characterized by few combinations of code elements and low bar code density. Wide-range levelling can be realized by using few combinations of code elements. Good conditions are created for long-distance measurement of barcode positioning, and measurement reliability is raised.

Owner:谢佑坤 +3

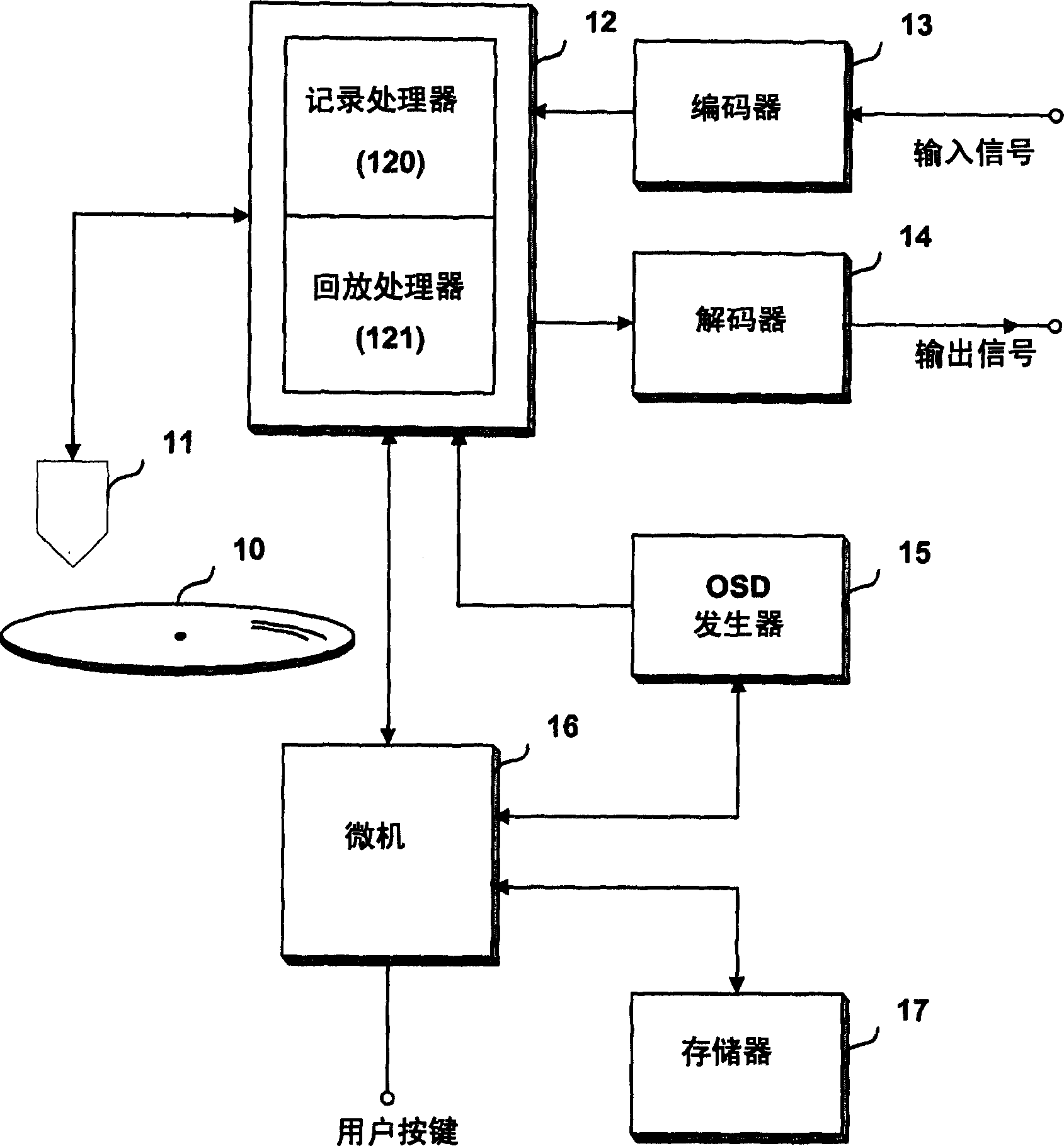

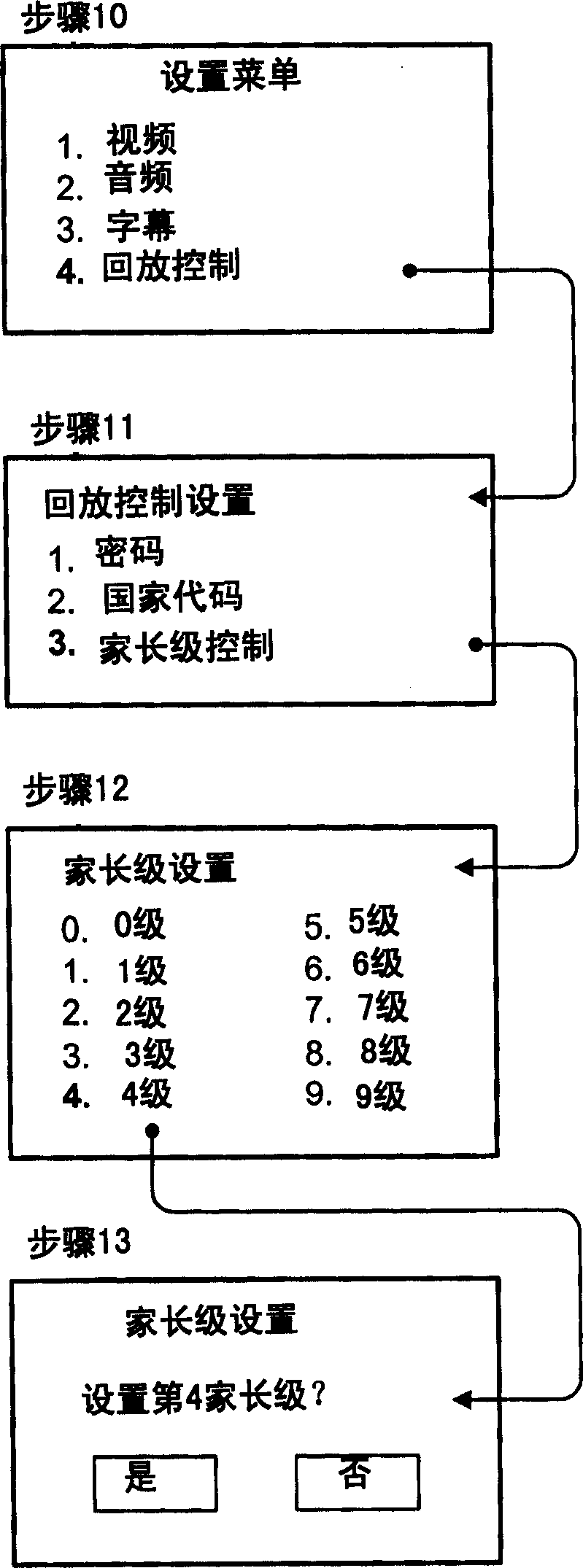

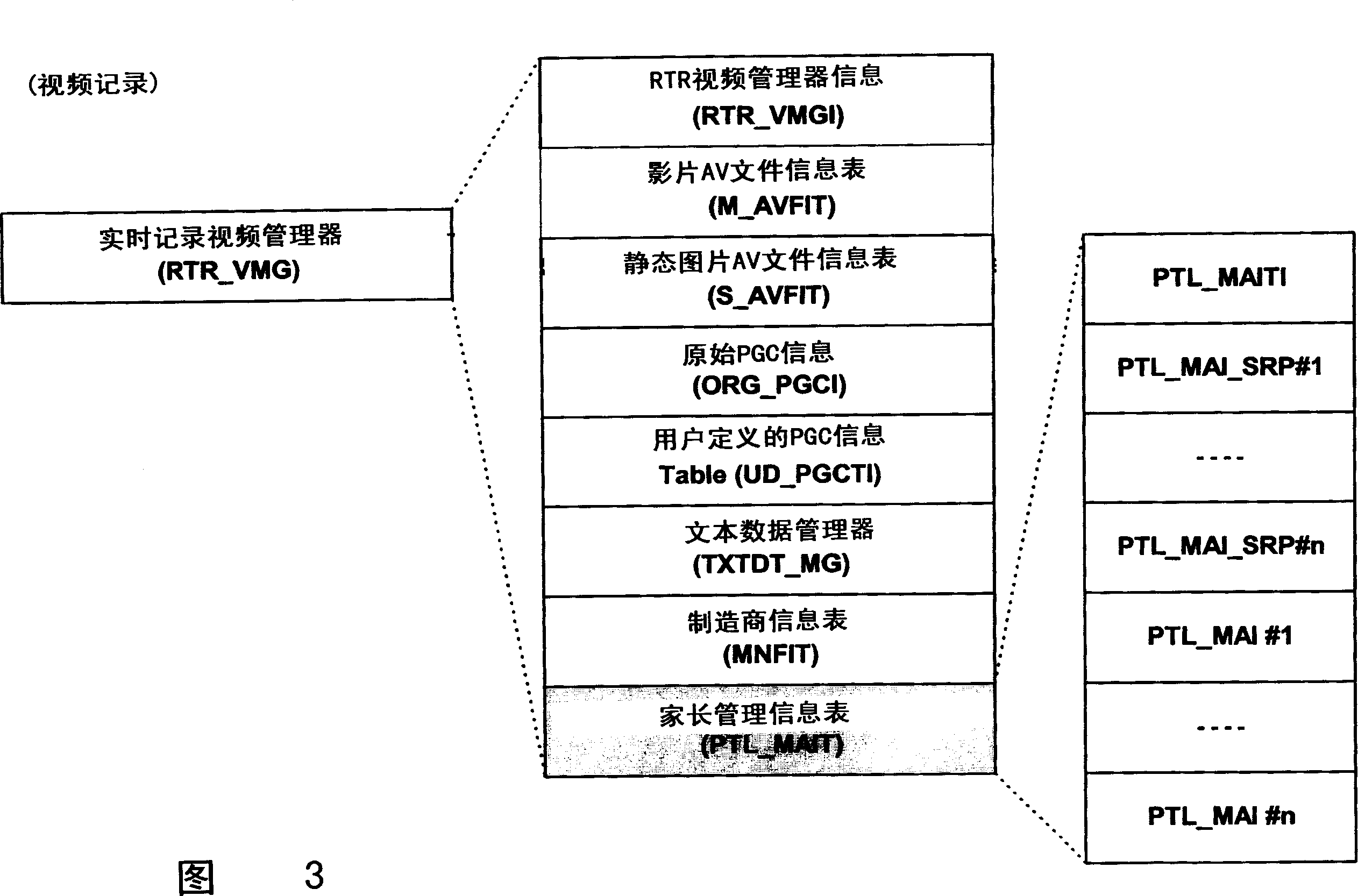

Apparats and method for manging parental level of optical disc

InactiveCN1538435ARecord information storageCarrier indexing/addressing/timing/synchronisingData streamChild and adolescent

Method and apparatus for managing a parental level of an optical disc can allow a user to set a parental level of a data stream recorded and stored on a rewritable optical disc or write-once optical disc, and can record and manage the set parental level as navigation information such as for the optical discs. The method and apparatus allow the user to conveniently set or change the parental level of the data stream, refer to the parental level recorded and managed therefore, and carry out a parental locking operation such that children or teenagers cannot arbitrarily reproduce a data stream of an adult program. Further, a parental grade code, a supplemental parental grade code or if the parental code was generated using parental management information previously supplied by the user can be determined. Accordingly, an authorized user can determine whether the previous set grade code is changed illegally.

Owner:LG ELECTRONICS INC

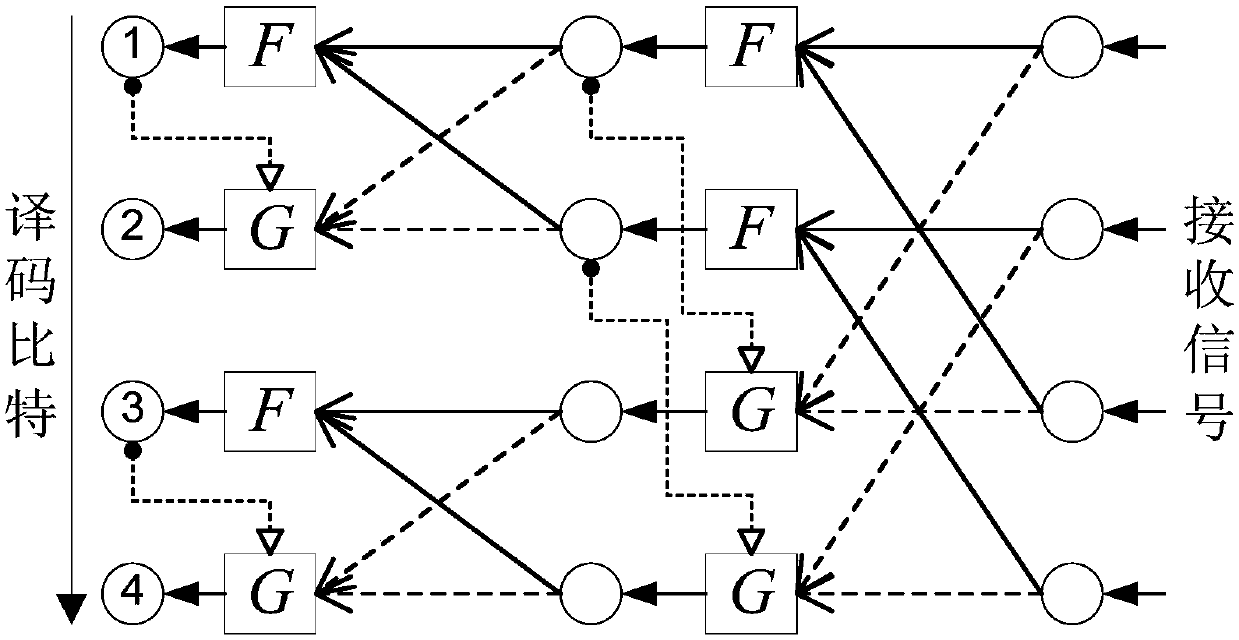

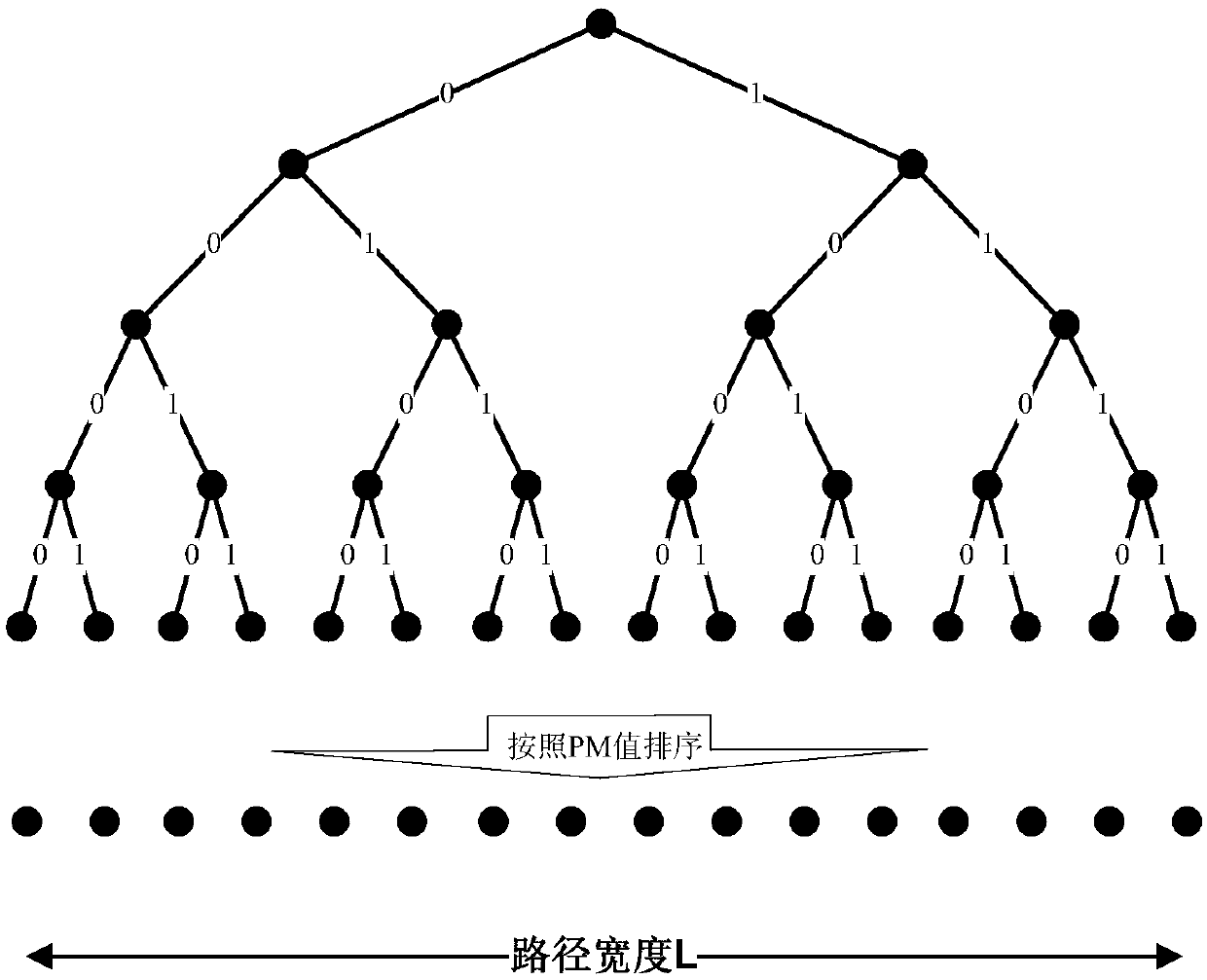

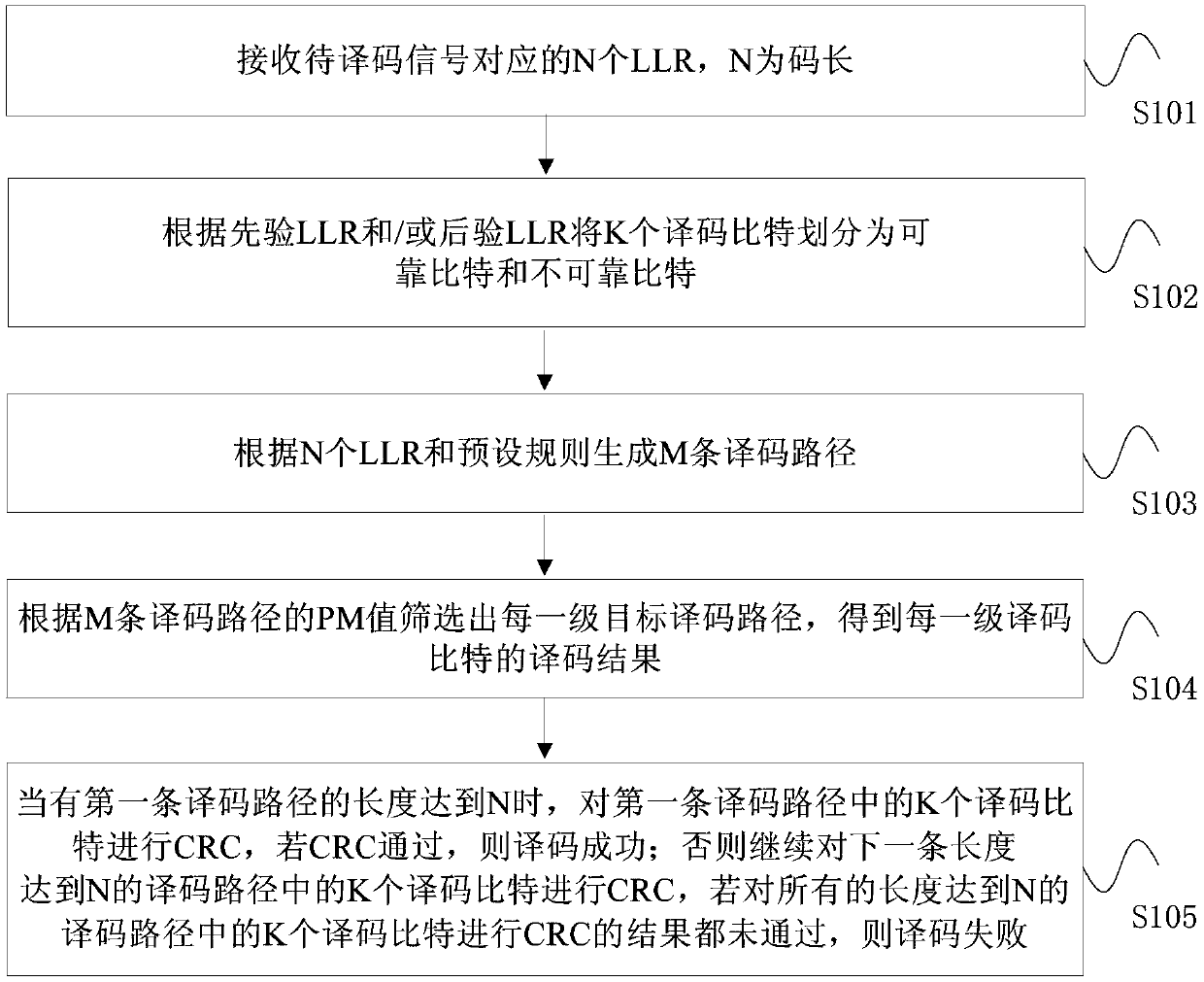

Decoding method and device, decoder

Embodiments of the present invention provide a decoding method and device, and a decoder. The method includes: receiving N LLRs corresponding to the signal to be decoded, dividing the K decoding bits into reliable bits and unreliable bits according to a priori LLR and / or a posteriori LLR, and generating M according to the N LLRs and preset rules There are 1 decoding paths, the next-level path for reliable bits is 1, and the next-level paths for unreliable bits are 2. According to the PM value of the M decoding paths, the target decoding paths of each level are screened out, and each target decoding path is obtained. When the length of the first decoding path reaches N, perform CRC on the K decoding bits in the first decoding path, if the CRC passes, the decoding is successful; otherwise Continue to perform CRC on the K decoding bits in the next decoding path whose length reaches N. If the result of performing CRC on all K decoding bits in the decoding path whose length reaches N is not passed, then decoding fail.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com