Bar gauge by grading coding

A hierarchical coding and barcode technology, which is applied in the field of measuring instruments, can solve the problems of high barcode density, difficulty in barcode recognition, and many symbol combination states, and achieve the effect of low barcode density, low difficulty in barcode recognition, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but this embodiment is not intended to limit the present invention, and any structure similar to the present invention or equivalent replacement should be included in the protection scope of the present invention.

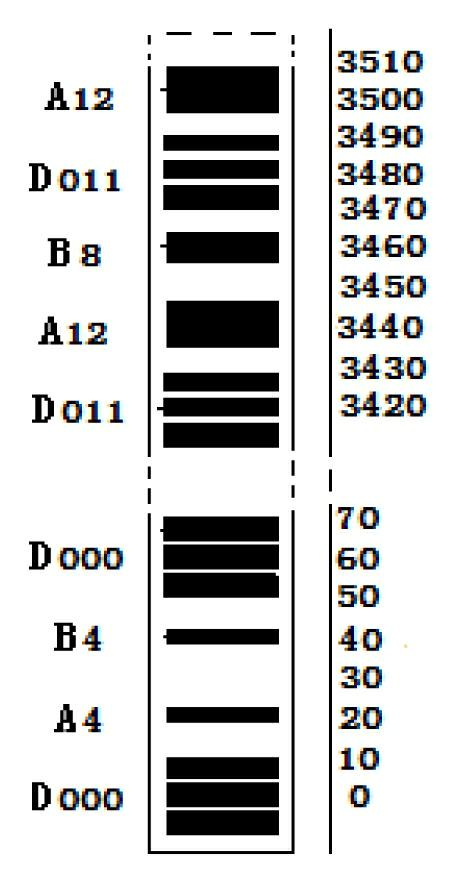

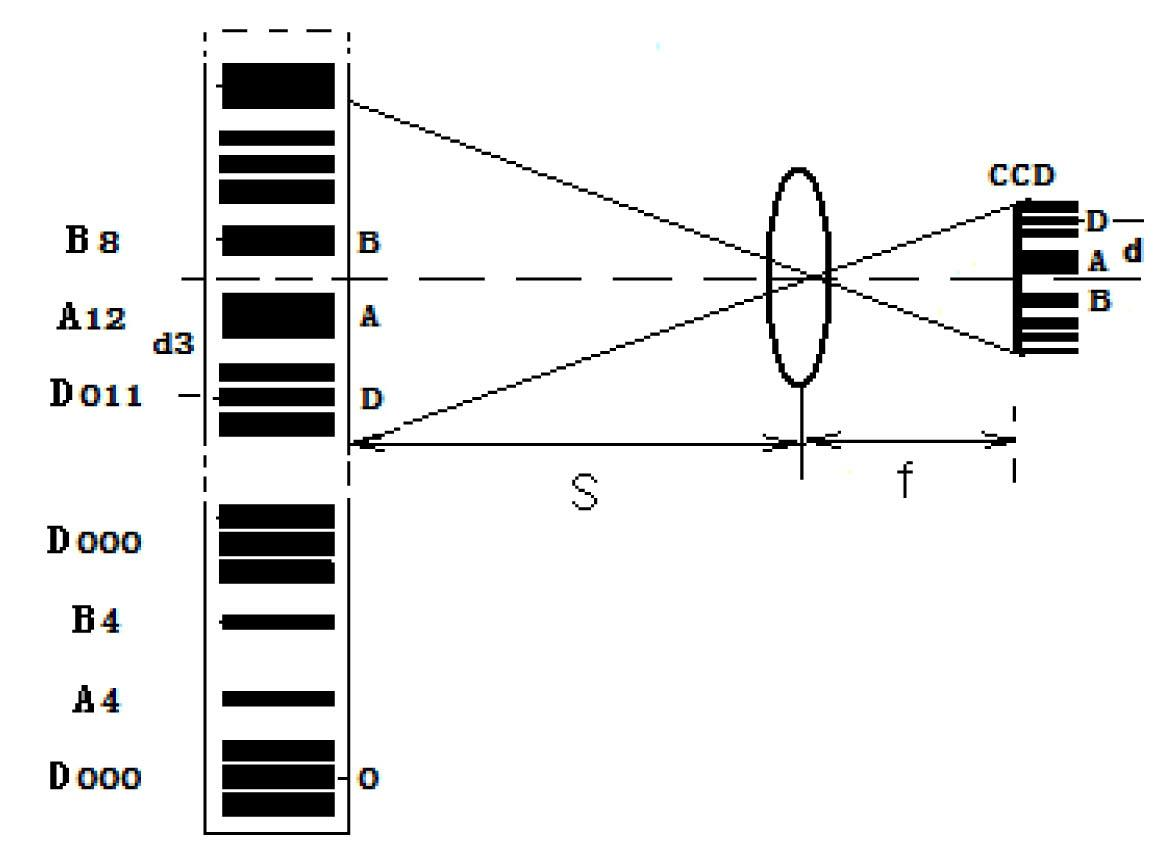

[0022] Such as figure 1 As shown, a kind of graded coding bar code scale provided by the embodiment of the present invention, the bar code scale is marked with bar code type scale, it is characterized in that:

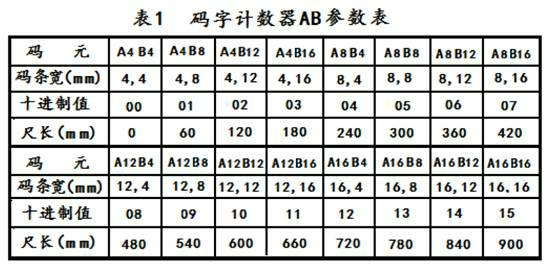

[0023] The barcode-type scale has a total length of 7680 mm, and is equally divided into 8 code segments arranged in sequence from the beginning to the end, and each code segment is equally divided into 16 code words arranged in sequence from the start to the end, and each code word is equally divided into 3 code elements arranged in sequence from the beginning to the end, the center distance between every two adjacent code elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com