Sectional homogenizing regulating and controlling method based on original tobacco formula module splitting

A homogenization and formulation technology, applied in tobacco, tobacco preparation, application, etc., can solve problems such as inability to obtain chemical values, unfavorable regulation of homogenization, and confusion in the storage of cigarette boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

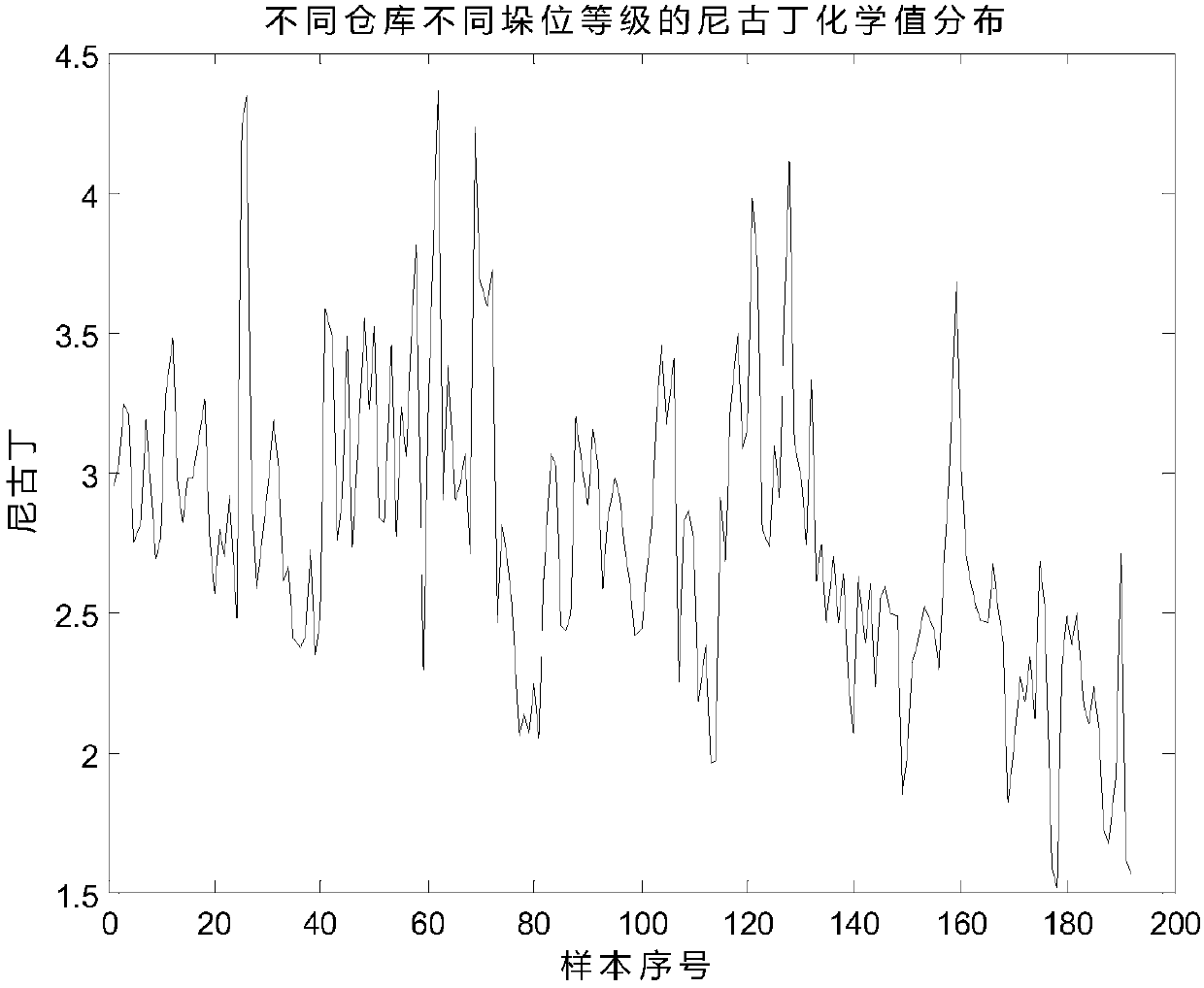

[0041] According to step 1 and step 2, the middle tobacco leaf formula module is selected as the experimental grade, the total amount is 23167.88 tons, and the grade of raw tobacco is 20 grades. The chemical value in the raw tobacco warehouse is sampled, and several samples are taken for each grade. More grades are taken, and less grades are taken. The number of samples for each grade is distributed between 2-10. After sampling, the laboratory detects near-infrared, and a total of 192 chemical values of tobacco leaf samples are obtained. The chemical value distribution of nicotine in different warehouses and different stack grades is as follows: figure 1 shown.

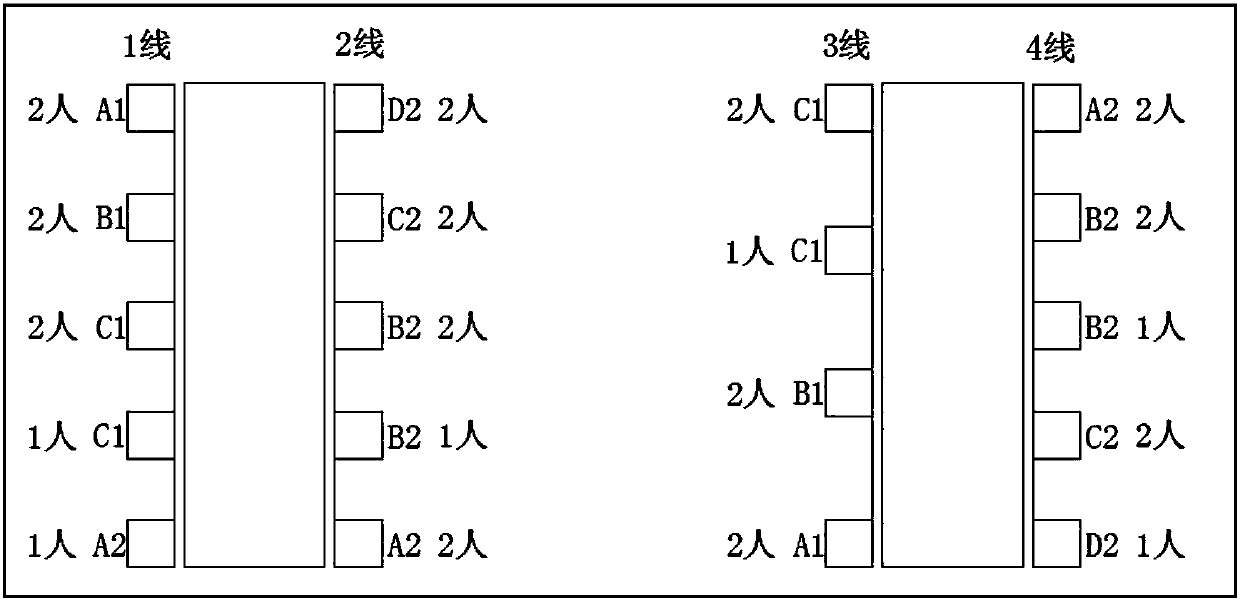

[0042] According to step 3, the chemical value original tobacco formula module distribution table is formed, as shown in Table 1, and nicotine (nicotine value) is selected as the control index.

[0043] Table 1: Chemical value information table of raw tobacco formula module

[0044]

[0045]

[0046] The n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com