Method for representing filling values of cut tobaccos by aid of operating parameters of cigarette making machines

A technology of operating parameters and filling value, which is applied in the field of tobacco technology, and can solve problems such as differences in filling values of detection values and easy drop of shredded tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

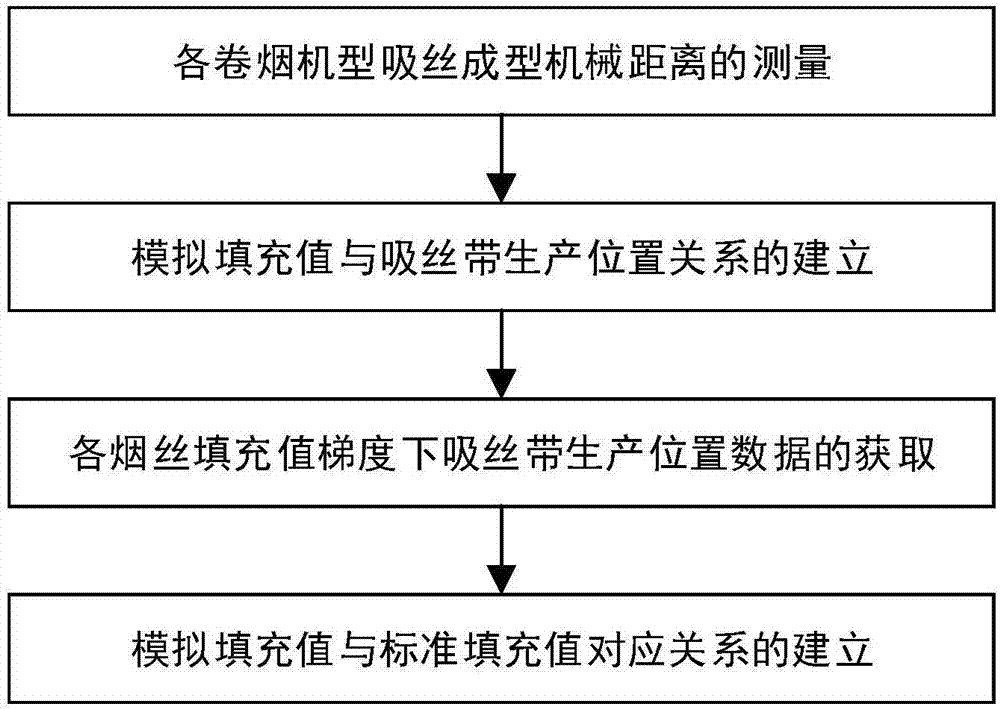

Method used

Image

Examples

Embodiment

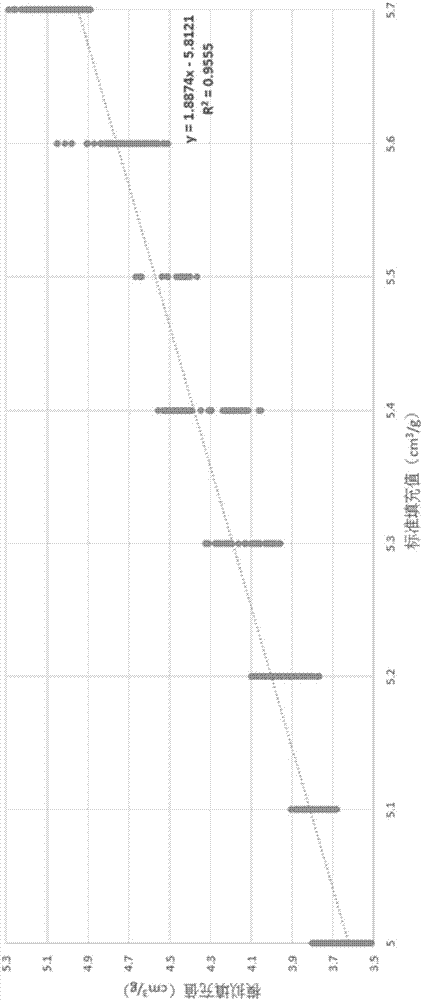

[0031] Example: Analysis and evaluation of the real-time shredded tobacco filling value of a certain brand of Liqun produced by the ZJ112 cigarette making machine.

[0032] Specific steps are as follows:

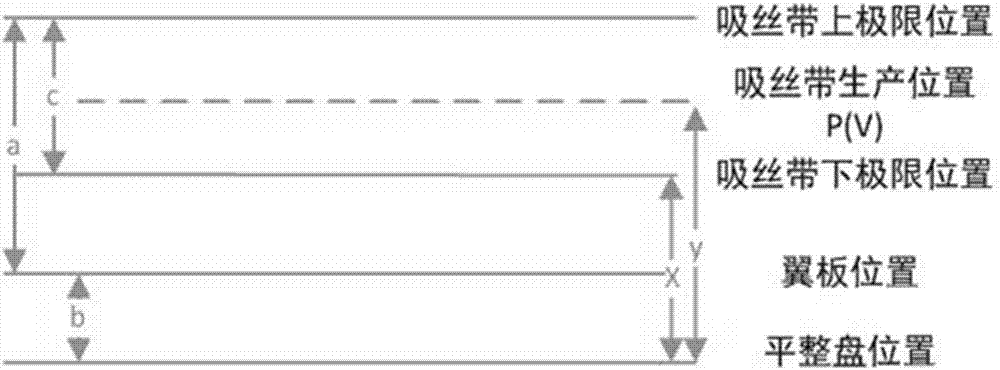

[0033] Step 1, the establishment of the position of the suction ribbon and the distance between the suction ribbon and the leveler, such as figure 2 As shown, when the suction ribbon is raised to the upper limit, measure the distance a from the upper limit of the suction ribbon to the wing plate, drop the air chamber cavity, measure the distance b from the position of the wing plate to the flat disc, and move the suction ribbon to the lower limit , Measure the distance c between the upper and lower limits of the suction ribbon. After measurement, a=7.70mm, b=0.40mm, and c=3.78mm of the test ZJ112 cigarette making machine.

[0034] Step 2. The establishment of the relationship between the simulated filling value and the production position of the suction ribbon:

[0035] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com