Method for setting feed amount of multi-level code disc used for NC-plain compatible machine tool with multiple operation modes

A technology of feed rate and classification, applied in the direction of digital control, electrical program control, etc., can solve the problems of high requirements for CNC lathes and restrictions on the large-scale promotion of CNC lathes, and achieve the effect of high man-machine function and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

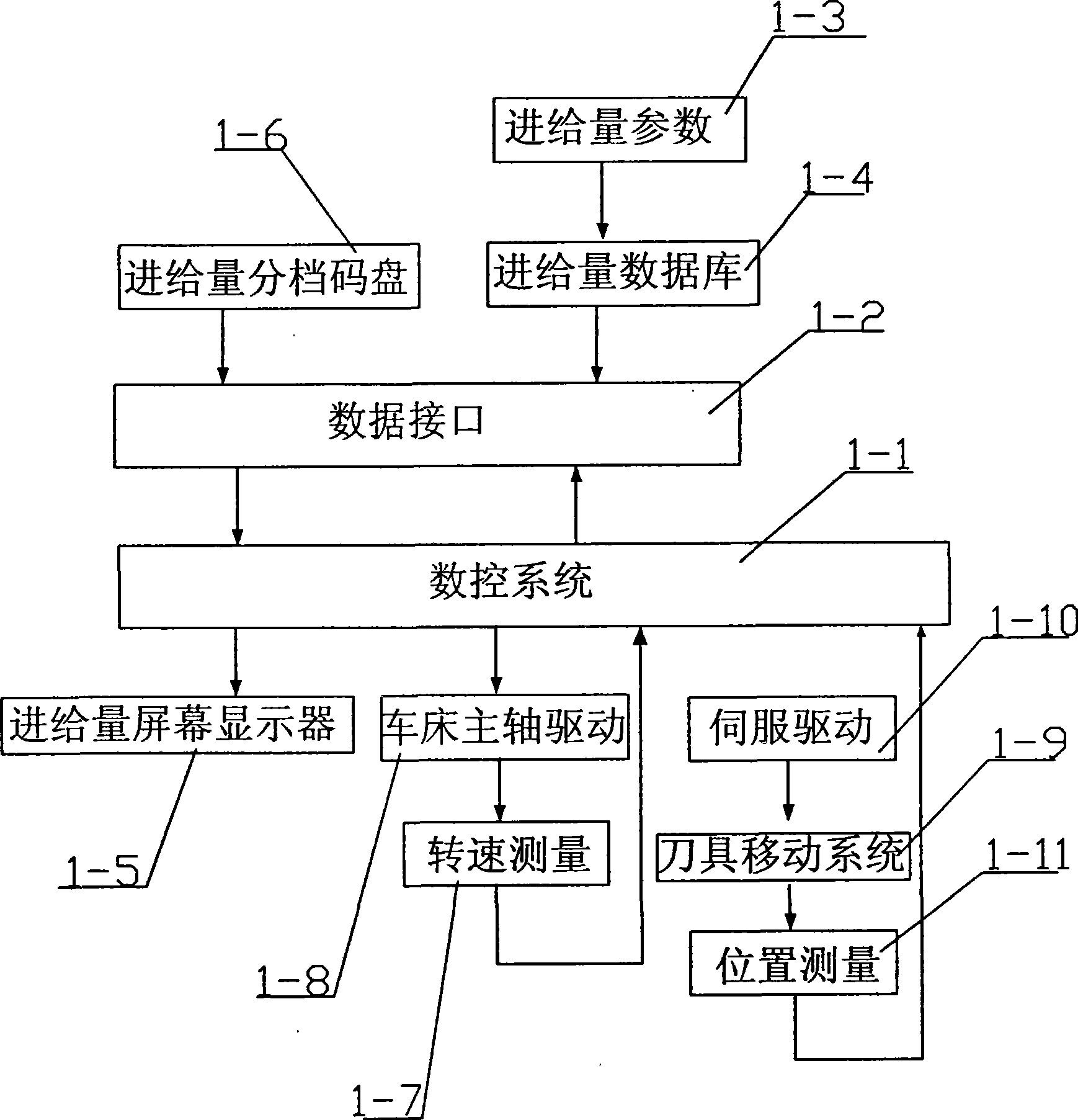

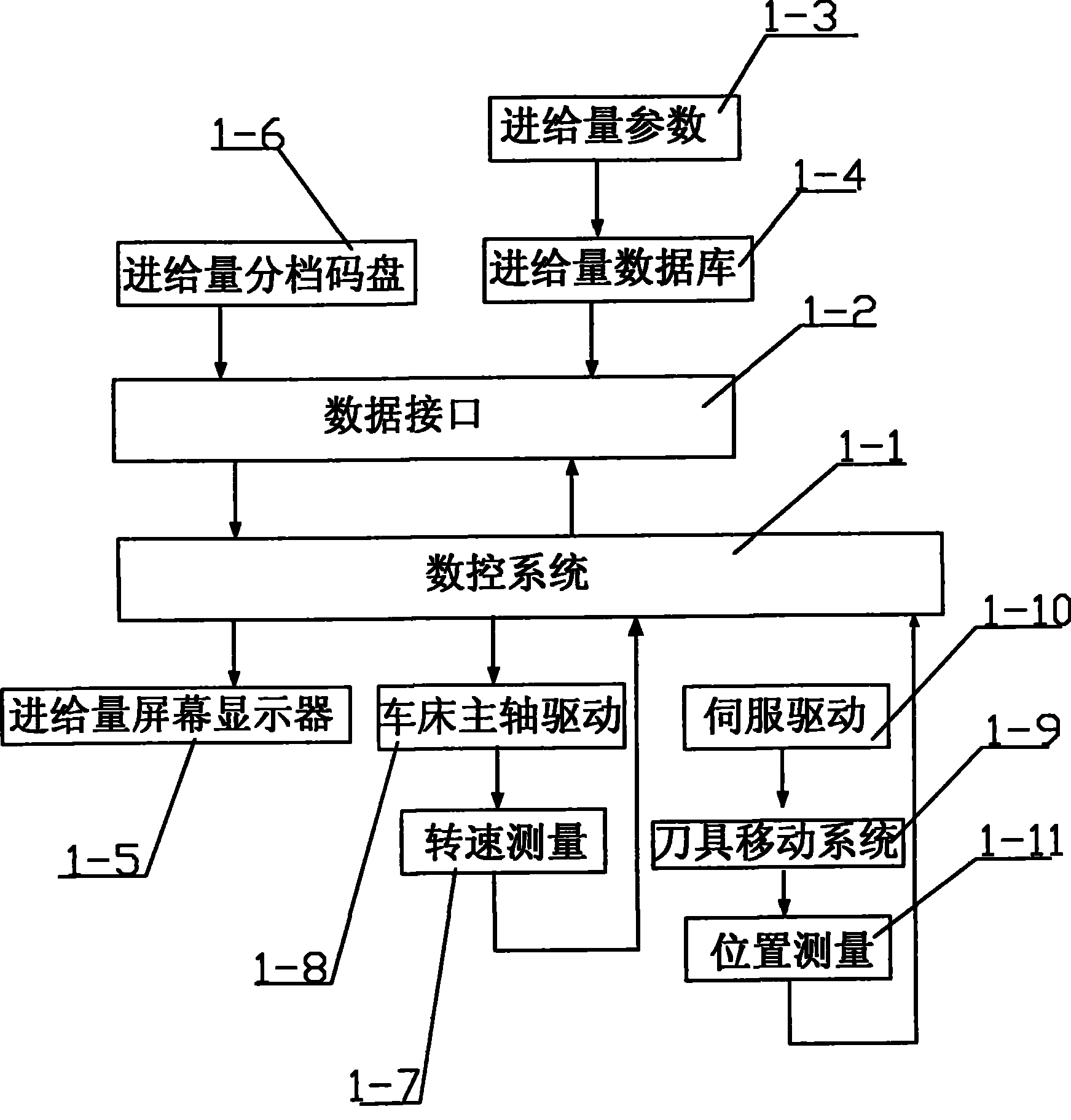

[0030] Embodiment 1: The numerical control lathe of the present invention uses the method for setting the feed rate with a step-by-step code disc,

[0031] (1) Input the feed amount parameter 1-3 of the machine tool into the feed amount database 1-4, and input the feed amount database 1-4 into the numerical control system 1-1 of the CNC lathe through the data interface 1-2;

[0032] Input the six feed modes of ordinary lathes, longitudinal feed rate, lateral feed rate, metric thread, inch thread, modulus thread, diameter pitch thread, and detailed feed parameters into the database 1-4, and the database 1-4 input the numerical control system 1-1 of the numerical control lathe through the data interface 1-2.

[0033] (2) Distribute the parameters of each mode in an 8×8 matrix table.

[0034] (3) Set a sub-level code disc 1-6 for the selection of feed parameters on the operation panel on the machine tool, and there are scales on the sub-level code disc 1-6, and each scale corres...

Embodiment 2

[0041] Embodiment 2: Use the method of setting the feed amount in steps with two step-by-step code discs in the numerical control lathe of the present invention.

[0042] Its main steps are the same as above, the difference is that there are two sub-level code discs.

[0043] Each division of the first 8-digit subdivision code wheel 1-6 corresponds to one of the six feed parameters in the database. When an 8-digit subdivision code disc is selected, the real-time display on the display is arranged in a matrix. An 8×8 matrix arrangement table of such feed parameters.

[0044] Each division of the second 64-bit division code disc corresponds to a feed parameter arranged in a matrix.

[0045]The specific operation steps are as follows:

[0046] First of all, toggle the stepped / stepless switch to the stepped state, and activate the feed parameter to control the step dial switch. Call out the thread database; dial the first 8-digit sub-code disc, and select an 8×8 thread pitch pa...

Embodiment 3

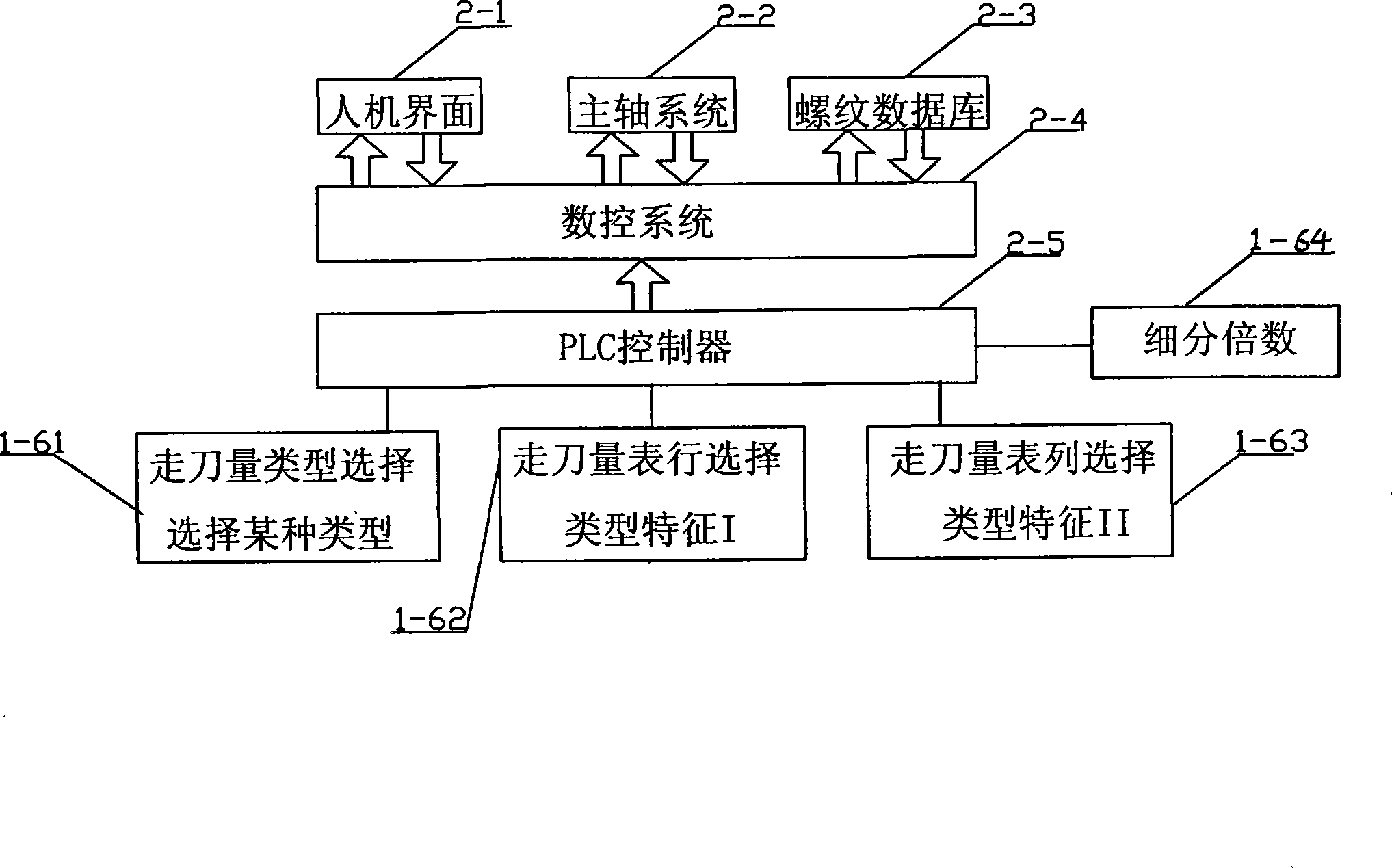

[0051] Embodiment 3: The method for setting the feed rate with three sub-grade turntables for the CNC lathe of the present invention,

[0052] See Fig. 3, its main steps are the same as example 1, the difference is that three 8-bit sub-level code discs are provided.

[0053] The program block flow chart of the present invention. Man-machine interface 2-1, spindle system 2-2, thread database 2-3 connected to data system 2-4; 3 sub-level code discs, the first sub-division code disc 1-61, for the selection of the type of cutting amount, Each bin corresponds to a type of feed parameter in the database, and the man-machine interface 2-1 displays a feed parameter arranged in a matrix in real time; the second bin code disc 1-62 , for the line selection of the feed amount table, and each sub-level corresponds to a row in a feed amount parameter arranged in a matrix; the third sub-level code disc 1-63 is for the selection of the feed amount table column, Each sub-level corresponds to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com