Device and method of measuring surface topographies of mirror and mirror-like objects

A technology for object surface and shape measurement, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unguaranteed convergence, multiple phase shifts of phase shift algorithms, and expensive laser trackers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

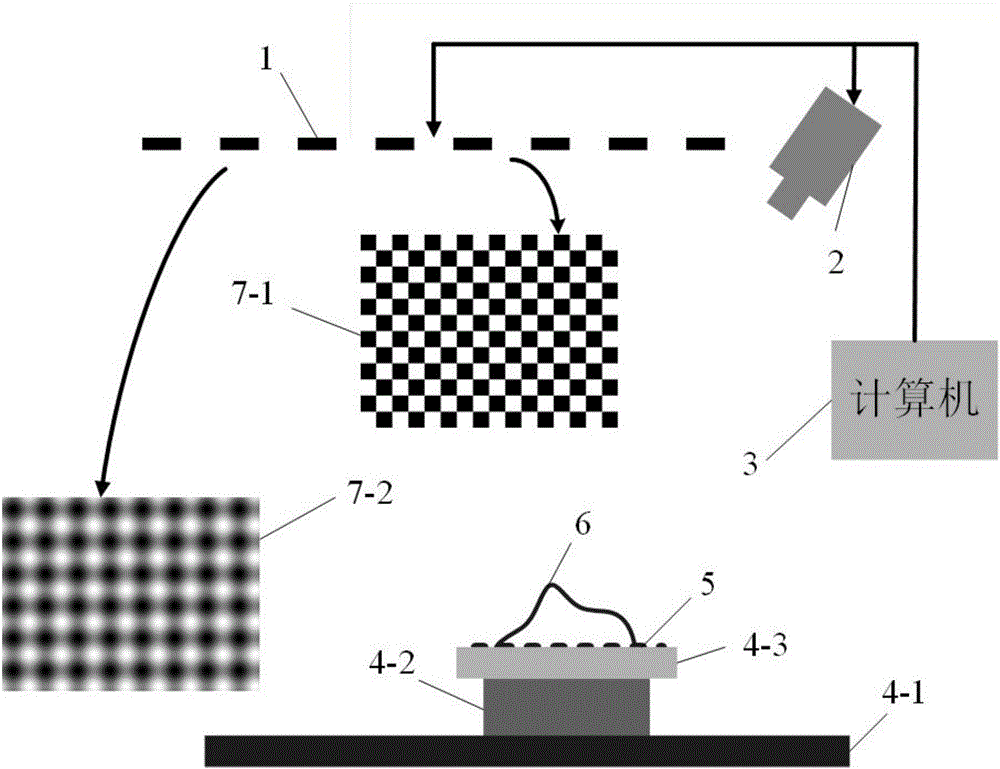

[0032]The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0033] The invention realizes the system calibration of the phase deflection technique on the basis of only using the free-moving plane mirror four times, and completes the matching of the same-named points by combining the absolute phase obtained by the Fourier transform method, and obtains the three-dimensional shape of the mirror object by using the gradient integral calculation. It greatly simplifies the system calibration process and realizes real-time and fast three-dimensional detection; at the same time, it ensures the authenticity of the measurement results and the ability to resist noise.

[0034] Such as figure 1 As shown, a device for measuring the surface topography of mirror surfaces and mirror-like objects includes: a liquid crystal display 1 for projecting checkerboard images 7-1 and two-dimensional sinusoidal stripes 7-2, and a C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com