Device for detecting surface shape of optical aspheric surface by sub-aperture stitching interferometer

A technology of interference detection and aperture splicing, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve problems such as the inability to meet the requirements of medium and high frequency band analysis, and achieve widening horizontal and vertical dynamic ranges, low test costs, and improved measurement. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

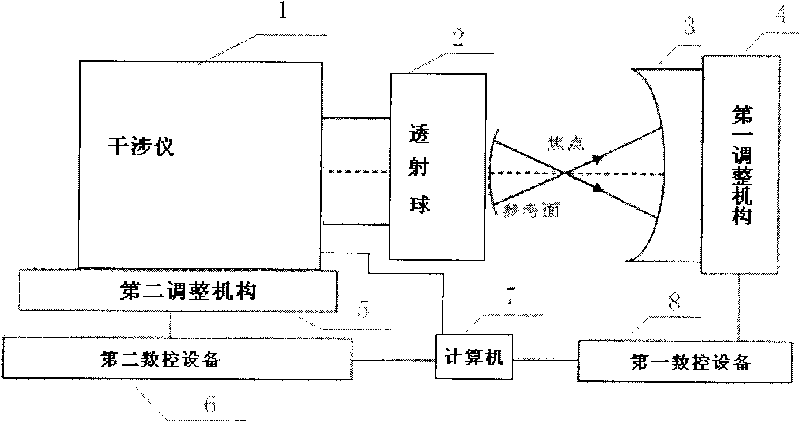

[0024] Such as figure 1 As shown, the device of the sub-aperture splicing interference detection optical aspheric surface shape of the present invention comprises an interferometer 1, a transmission sphere 2 and a computer 7; the transmission sphere 2 is fixed at the light hole of the interferometer 1; The aspheric surface 3 is fixed on the first adjustment mechanism 4, and the computer 7 controls the action of the first adjustment mechanism 4 through the first numerical control device 8 to adjust the translation and rotation of the optical aspheric surface 3 to be measured; the interferometer 1 is fixed on the On the second adjustment mechanism 5 , the computer 7 controls the action of the second adjustment mechanism 5 through the second numerical control device 6 to adjust the translation of the interferometer 1 and the transmission ball 2 .

[0025] The first adjustment mechanism 4 adopts a currently known six-dimensional numerical control precision adjustment mechanism, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com