Conditioner for Chemical Mechanical Planarization Pad

a technology of mechanical planarization and conditioner, which is applied in the direction of grinding drive, grinding drive, manufacturing tools, etc., can solve the problems of inability to play the role of the pad surface, uneven surface of the pad, and inability to meet the needs of the industry, so as to achieve uniform dressing, superior dressing efficiency and performance reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

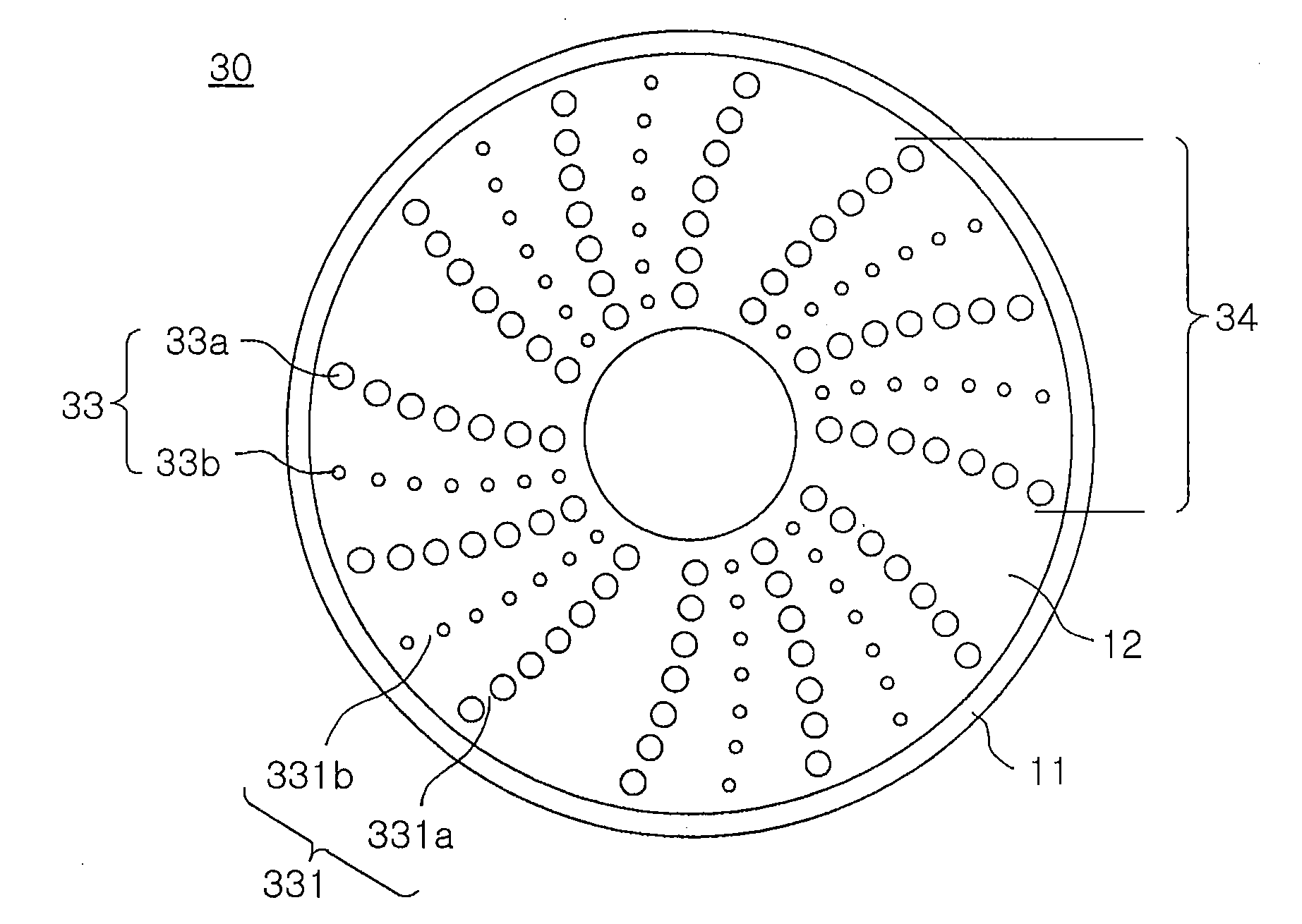

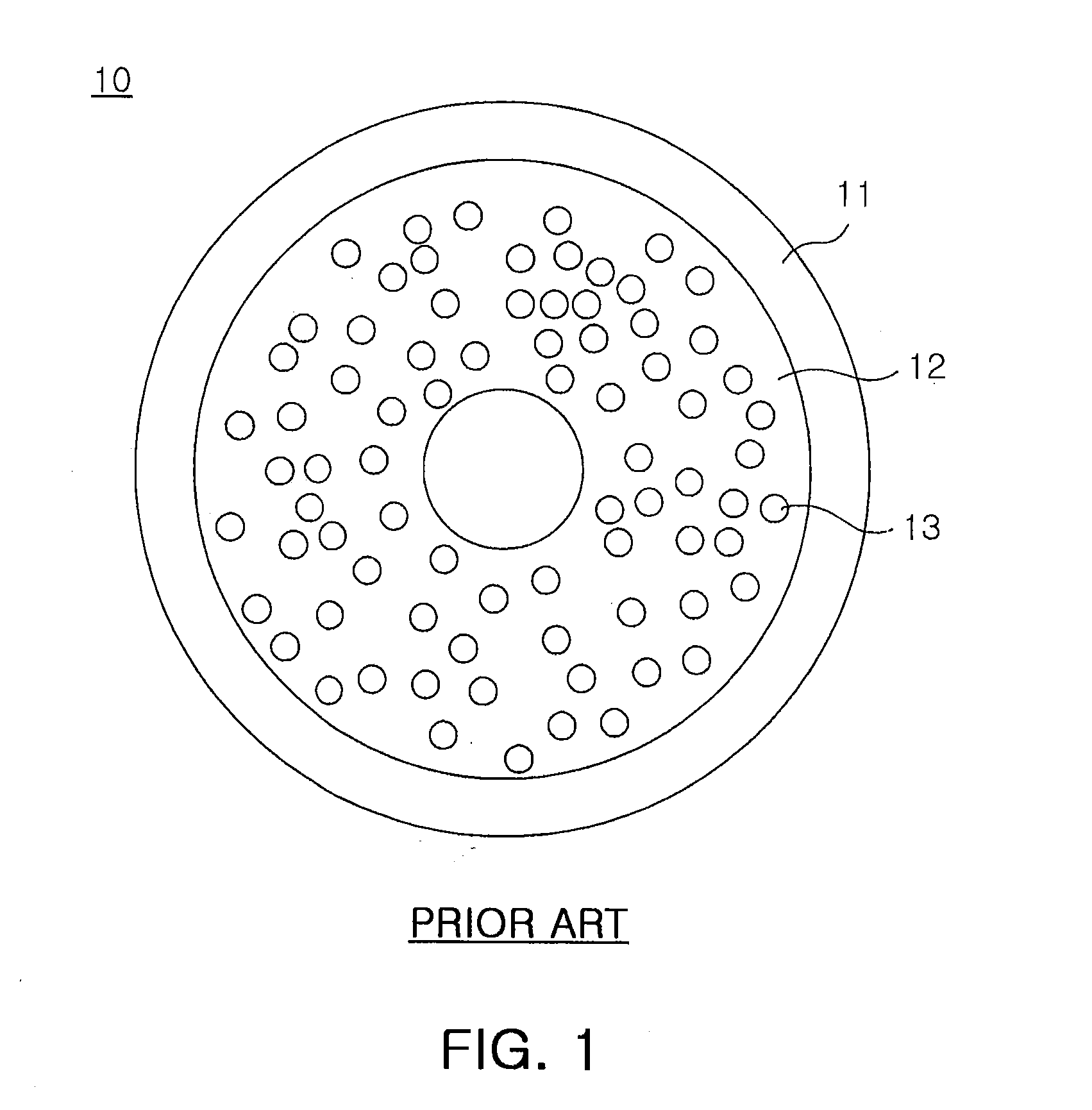

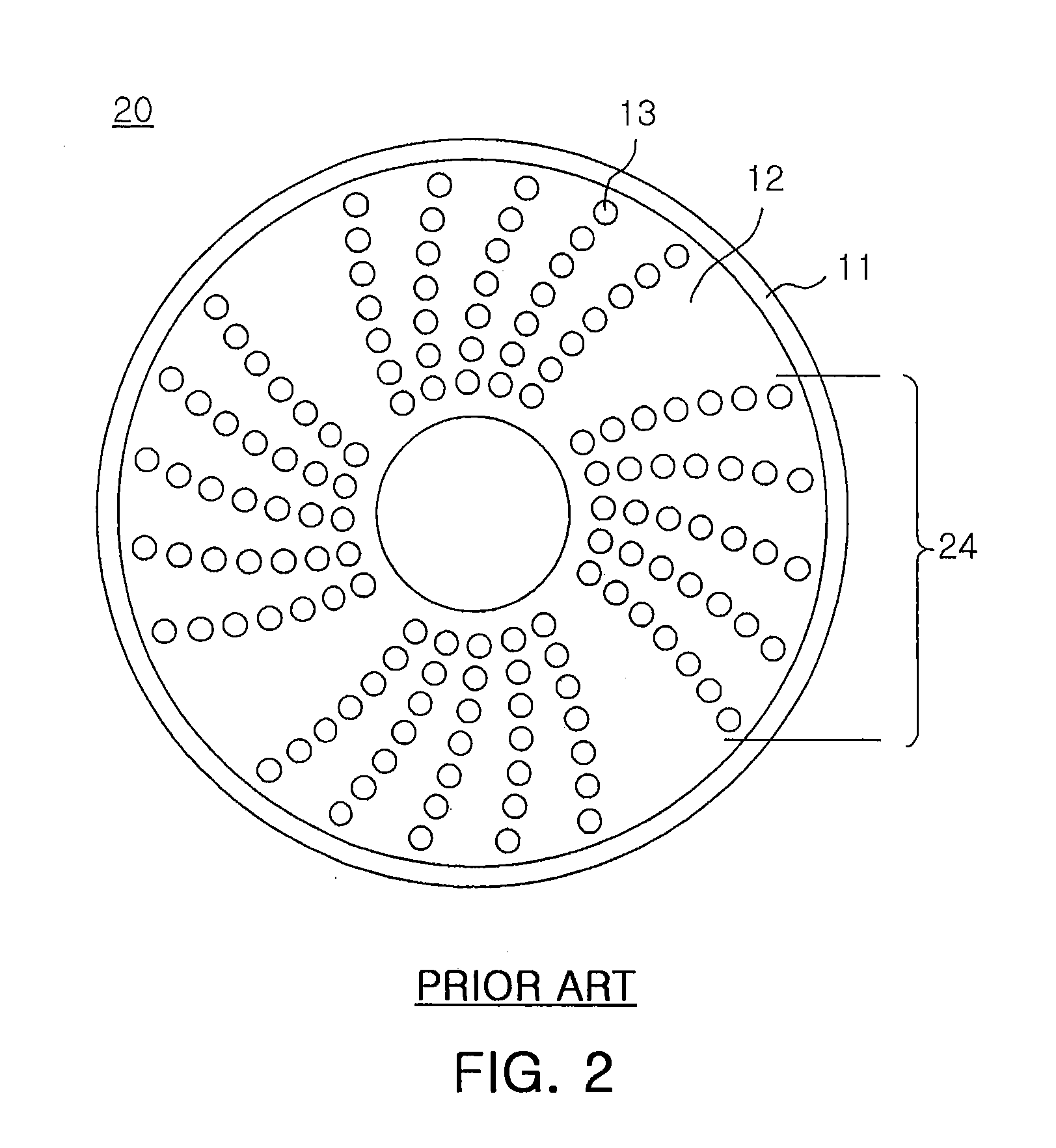

[0084]The products prepared include a conditioner of random arrangement having abrasive particles without size difference randomly arranged (conventional product 1), a conditioner of conventional patterning having abrasive particles without size difference regularly arranged (conventional product 2), a conditioner of the invention having at least 2 abrasive particles with size difference alternately attached in a row to a segment (inventive product 1), a conditioner of the invention having at least 2 abrasive particles with size difference alternately attached to each segment (inventive product 2), and a conditioner of the invention having abrasive particles attached in a row forming a circle (inventive product 3).

[0085]With respect to the conventional conditioner and the conditioner of the invention, an evaluation was conducted on cut rate of pad and fracture of abrasive particles. The results are shown in table 1.

TABLE 1Evaluation resultsFracture orPad cut rate (μm / hr)pulling out ...

example 2

[0089]The products prepared include a conditioner (comparative product 1) representing less than 10% size difference between bigger and smaller abrasive particles, a conditioner (inventive product 4) having abrasive particles with 10 to 40% of size difference and a conditioner (comparative product 2) having abrasive particles with 45 to 70% of size difference. The products have bigger and smaller abrasive particles in a row at a predetermined rate.

[0090]For the conditioners manufactured as just described, wafer removal rate was measured on a time basis and the results are shown in table 2 below.

TABLE 2Wafer removal rate (Å / min)20401 hourhourshoursAveragevariationComparative3642328727693233873product 1Inventive product 43685351433973532288Comparative39913102255432151437product 2

[0091]As shown in Table 2, for comparative product 1 having abrasive particles with less than 10% size difference, wafer removal rate after 40-hour use drops significantly from the initial removal rate.

[0092]T...

example 3

[0097]Manufactured were conditioners having bigger abrasive particles, mid-sized abrasive particles and smaller abrasive particles with 10-40% of overall size difference arranged in a row. With respect to the conditioners, an evaluation was conducted on cut rate of pad and the results are shown in Table 3 below.

[0098]In Table 3 below, inventive product 5 is a conditioner having bigger abrasive particles A, mid-sized abrasive particles B and smaller abrasive particles C arranged successively in a row. Inventive product 6 is a conditioner having bigger abrasive particles A, smaller abrasive particles C and mid-sized abrasive particles B arranged successively in a row. Conventional product 1 is a conditioner having abrasive particles without size difference arranged randomly.

TABLE 3Pad cut rate (μm / hr)1st2nd3rdAveragevariationInventive product 545744946145612Inventive product 645545744045117Conventional product 132235729832559

[0099]As shown in table 3, if abrasive particles have 10 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| abrasive | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com