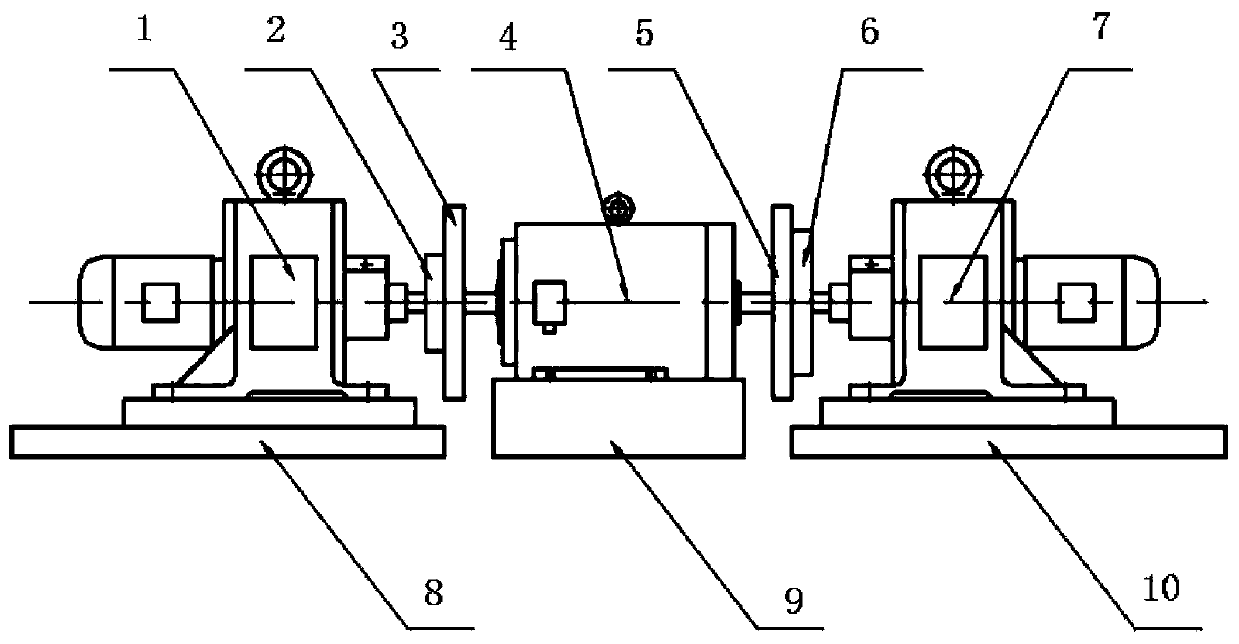

Method for cyclic online grinding and dressing ceramic binding agent cubic boron nitride (CBN) grinding wheel

A ceramic bonding agent and bonding agent technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. Good consistency, high trimming efficiency and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The online dressing method of the CBN emery wheel of the present embodiment adopts the following steps:

[0025] (1) First, the high-speed steel workpiece is ground with a vitrified bond CBN grinding wheel. The specifications of the CBN grinding wheel are shown in Table 1, and the specifications of the high-speed steel workpiece are shown in Table 2.

[0026] Table 1 Vitrified bond CBN grinding wheel

[0027] CBN granularity CBN concentration (vol%) Grinding contact area Grinding wheel abrasive layer thickness Number of grinding wheels 100 / 120 75 35.6mm 2

3mm 5

[0028] Table 2 Specification parameters of high-speed steel

[0029] steel number Hardness (HRC) Bending strength (GPa) Impact toughness (MJm 2 )

Grinding effective area W18Cr4V 65 3.8 0.3 20

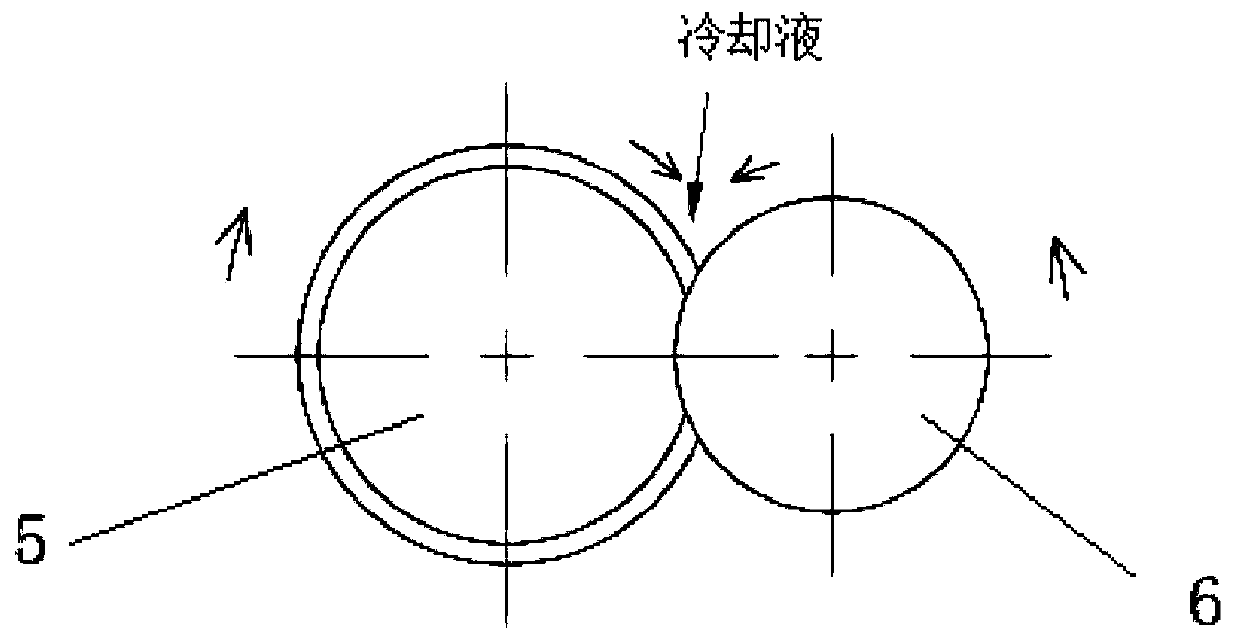

[0030] (2) When the CBN grinding wheel grinds the workpiece, the linear speed of the grinding wheel, the linear speed of the workpiece, and the fee...

Embodiment 2

[0046] The present embodiment is the same as the method of embodiment 1, only the following parameters are adjusted:

[0047] The dressing abrasive is corundum;

[0048] The grinding contact area of the CBN grinding wheel is 100mm2, and the thickness of the abrasive layer of the grinding wheel is 6mm.

[0049] The abrasive particle size of the CBN grinding wheel is 80#, and the particle size of the dressing abrasive is 150#.

[0050] The linear speed of the CBN grinding wheel is 40m / s, the linear speed of the dresser is 5m / s, and the feed speed of the workpiece is 0.2mm / min.

Embodiment 3

[0052]The present embodiment is the same as the method of embodiment 1, only the following parameters are adjusted:

[0053] The dressing abrasive is 50% (volume ratio) of corundum and silicon carbide;

[0054] The grinding contact area of the CBN grinding wheel is 10mm2, and the thickness of the abrasive layer of the grinding wheel is 1mm.

[0055] The abrasive particle size of the CBN grinding wheel is 220#, and the particle size of the dressing abrasive is 600#.

[0056] The linear speed of the CBN grinding wheel is 30m / s, the linear speed of the dresser is 1m / s, and the feed speed of the workpiece is 0.6mm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com