Grinding parameter optimization and manufacturing method of superhard consolidated abrasive based on adams simulation

A technology of grinding parameters and fixed abrasives, applied in the field of grinding processing, can solve the problem of uniform wear and tear of ultra-hard consolidated grinding discs rarely seen, so as to improve processing efficiency and utilization rate, improve stability, and maintain surface shape accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

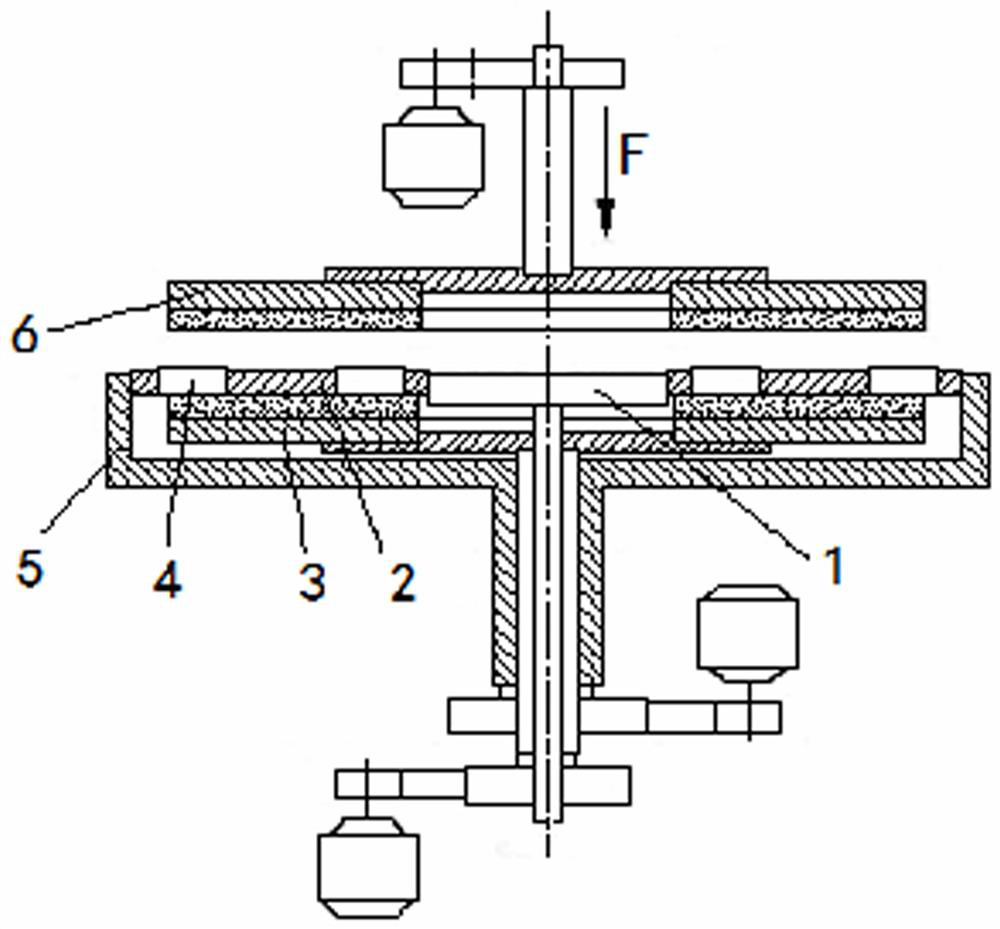

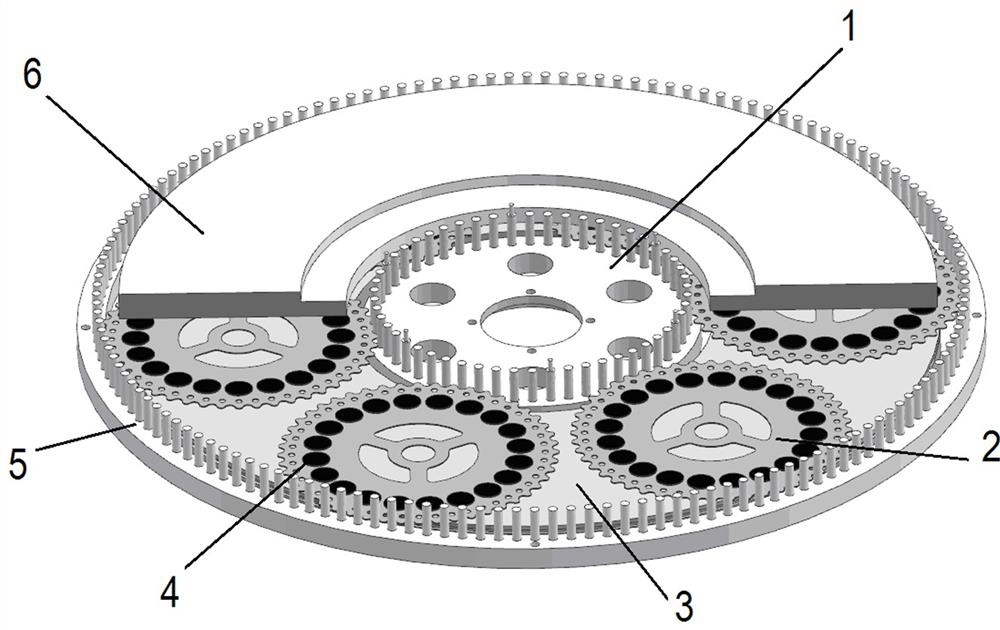

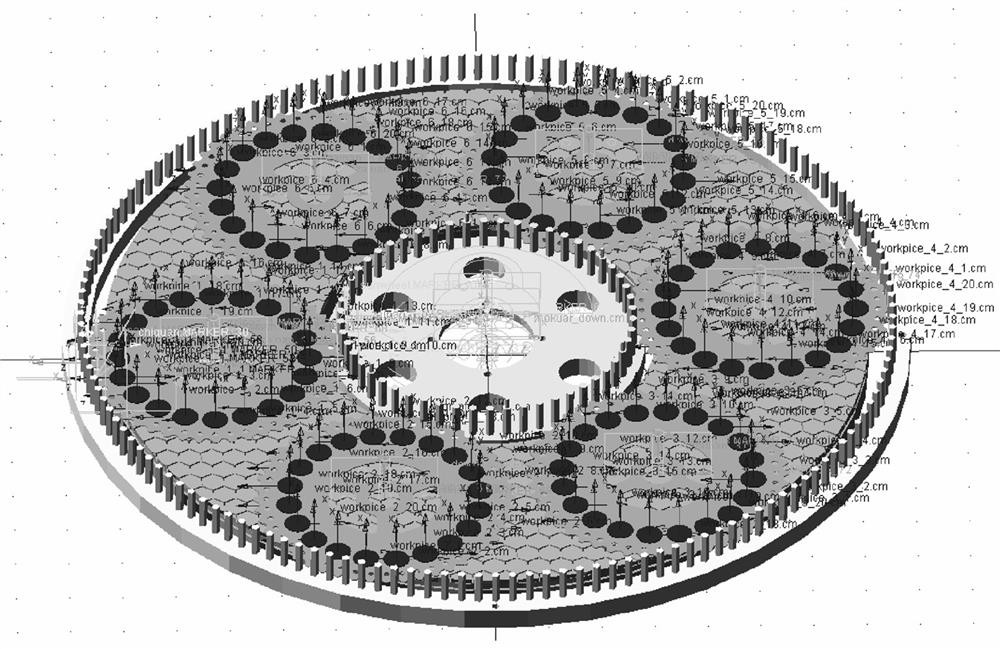

[0040] Such as figure 1 As shown, the center gear 1 (sun gear) is driven by a motor through a reducer, and drives 6 planetary gears 2 to revolve around its center. The internal meshing pin gear 5 is fixed on the grinding machine bed body (it can also be rotated). The planetary wheel 2 is placed on the grinding surface of the grinding disc 3, meshes with the center wheel 1 and the inner meshing pin gear 5 at the same time, and is driven by the center wheel 1 while revolving around its center and doing autorotation; each planetary wheel has 20 A through hole, the diameter of the through hole is slightly larger than the diameter of the workpiece, and the thickness of the planetary wheel is slightly smaller than the final machining size of the workpiece 4. The workpiece 4 is placed in the through hole of the planetary wheel 2, its lower surface is placed on the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com