A kind of nanometer multi-layer structure film and preparation method thereof for blade rolling die

A nano-multilayer and nano-coating technology, which is applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of insufficient oxidation resistance and heat resistance, cracking and peeling of TiN coating, etc. Achieve excellent mechanical properties, good bonding force, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

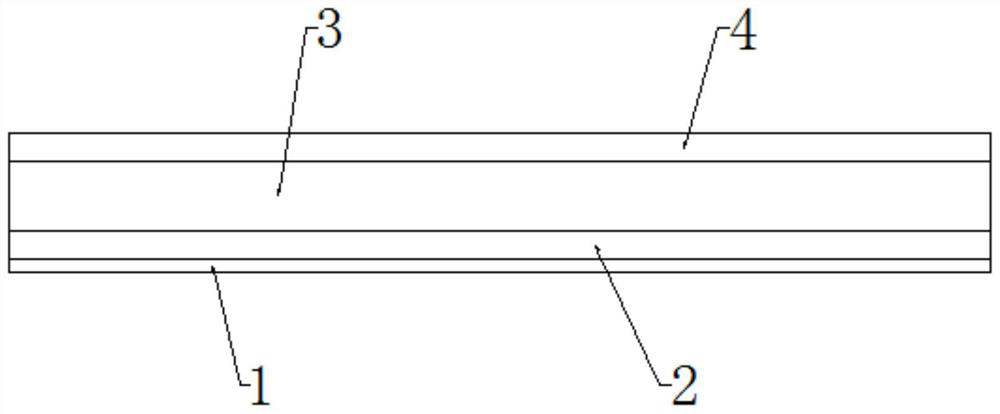

[0039] A kind of nano multi-layer structure film used for blade rolling die, its structure schematic diagram is shown in figure 1 .

[0040] The nano-multilayer structure film used for blade rolling dies includes four layers of metal TiAl bottom layer 1, TiAlN transition layer 2, TiAlN / CrTiAlN nano-multilayer coating 3, and CrTiAlN surface coating layer 4, with a total thickness of 5.4 μm ;

[0041] Among them, the thickness of the metal TiAl bottom layer 1 is 0.5 μm, the thickness of the TiAlN transition layer 2 is 0.7 μm, the total thickness of the TiAlN / CrTiAlN nano-multilayer coating 3 is 3.24 μm, and the thickness of the CrTiAlN surface coating layer is 0.96 μm.

[0042] The nano-multilayer structure film used for the blade rolling die is a metal TiAl bottom layer 1 in a vacuum degree of -3 Pa, the deposition temperature is 300°C, and the deposition time is 5 minutes to obtain the metal TiAl bottom layer 1;

[0043] TiAlN transition layer 2 is in a vacuum of -3 Pa, a Ti...

Embodiment 2

[0056] A nano-multilayer structure film for blade rolling die, including four layers of metal TiAl bottom layer 1, TiAlN transition layer 2, TiAlN / CrTiAlN nano-multilayer coating 3, and CrTiAlN surface coating layer 4, with a total thickness of 6 μm ;

[0057] Among them, the thickness of the metal TiAl bottom layer 1 is 0.6 μm, the thickness of the TiAlN transition layer 2 is 0.8 μm, the total thickness of the TiAlN / CrTiAlN nano-multilayer coating 3 is 3.6 μm, and the thickness of the CrTiAlN surface coating layer is 1 μm.

[0058] The nano-multilayer structure film used for the blade rolling die is a metal TiAl bottom layer 1 in a vacuum degree of -3 Pa, the deposition temperature is 250°C, and the deposition time is 6 minutes to obtain the metal TiAl bottom layer 1;

[0059] TiAlN transition layer 2 is in a vacuum of -3 Pa, the deposition temperature is 250°C, and the deposition time is 12 minutes to obtain the TiAlN transition layer 2;

[0060] TiAlN / CrTiAlN nano multi-la...

Embodiment 3

[0071] A nano-multilayer structure film for blade rolling die, including four layers of metal TiAl bottom layer 1, TiAlN transition layer 2, TiAlN / CrTiAlN nano-multilayer coating 3, and CrTiAlN surface coating layer 4, with a total thickness of 6 μm ;

[0072] Among them, the thickness of the metal TiAl bottom layer 1 is 0.3 μm, the thickness of the TiAlN transition layer 2 is 0.6 μm, the total thickness of the TiAlN / CrTiAlN nano-multilayer coating 3 is 3 μm, and the thickness of the CrTiAlN surface coating layer is 1.1 μm.

[0073] The nano-multilayer structure film used for the blade rolling die is a metal TiAl bottom layer 1 in a vacuum degree of -3 Pa, the deposition temperature is 350°C, and the deposition time is 4 minutes to obtain the metal TiAl bottom layer 1;

[0074] TiAlN transition layer 2 is in a vacuum of -3 Pa, the deposition temperature is 350°C, and the deposition time is 8 minutes to obtain the TiAlN transition layer 2;

[0075] TiAlN / CrTiAlN nano multi-lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com