A kind of polyurethane elastomer polishing material and preparation method thereof

A polyurethane elastomer and polishing material technology, which is applied in the field of polyurethane elastomer polishing material and its preparation, can solve the problems of difficult control of the preparation process, high production cost, and easy pollution of the environment, so as to avoid harm to health and repeat production High, good operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

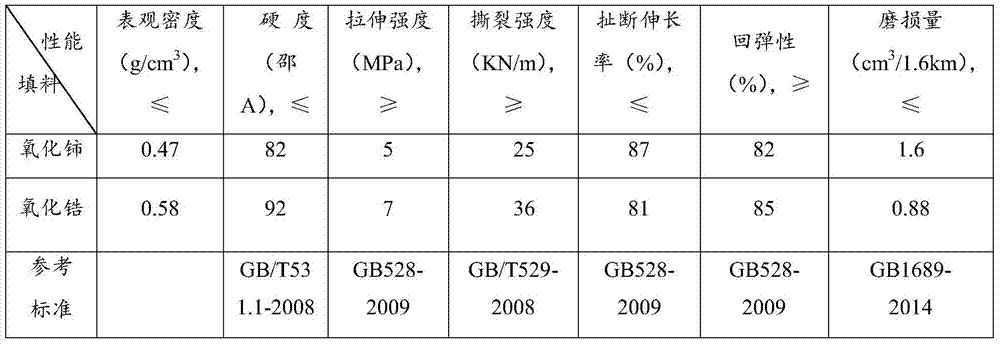

Embodiment 1

[0036] A kind of polyurethane elastomer polishing material in the present embodiment, it is made according to the weight ratio of 1:1 by component A and component B,

[0037] The component A is made from the following raw materials in parts by mass:

[0038] TDI type polyurethane prepolymer 94 parts

[0039] 4 parts of PAPI type polyurethane prepolymer

[0040] 2 parts of cerium oxide micropowder with particle size ≤10 μm;

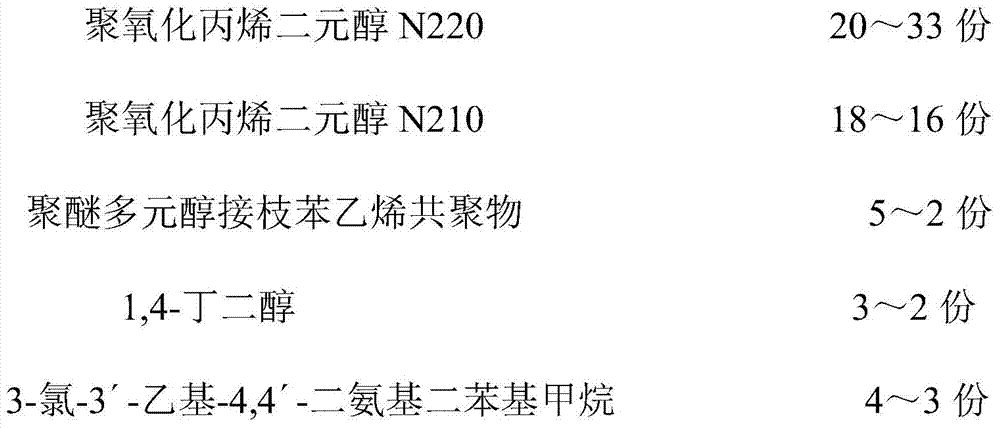

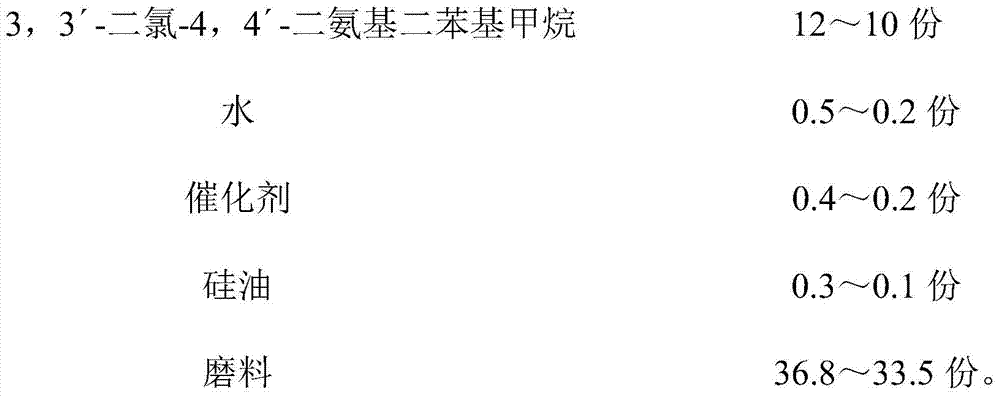

[0041] The component B is made from the following raw materials in parts by mass:

[0042]

[0043]

[0044] A method for preparing the polyurethane elastomer polishing material described in this embodiment, comprises the following steps:

[0045] 1) Preparation of component A: put 94 parts by mass of TDI type polyurethane prepolymer, 4 parts by mass of PAPI type polyurethane prepolymer and 2 parts by mass of cerium oxide micropowder with a particle size ≤ 10 μm in a mixer , stirred and mixed evenly at room temperature, filled with nitrogen and s...

Embodiment 2

[0057] A kind of polyurethane elastomer polishing material in the present embodiment, it is made according to the weight ratio of 1:1 by component A and component B,

[0058] The component A is made from the following raw materials in parts by mass:

[0059] TDI type polyurethane prepolymer 98 parts

[0060] 1 part of PAPI type polyurethane prepolymer

[0061] 1 part of zirconia micropowder with particle size ≤10μm;

[0062] The component B is made from the following raw materials in parts by mass:

[0063]

[0064]

[0065] A method for preparing the polyurethane elastomer polishing material described in this embodiment, comprising the following steps:

[0066] 1) Preparation of component A: put 98 parts by mass of TDI type polyurethane prepolymer, 1 part by mass of PAPI type polyurethane prepolymer and 1 part by mass of zirconia micropowder with a particle size of ≤10 μm in a mixer , stirred and mixed evenly at room temperature, filled with nitrogen and sealed for ...

Embodiment 3

[0073] A kind of polyurethane elastomer polishing material in the present embodiment, it is made according to the weight ratio of 1:1 by component A and component B,

[0074] The component A is made from the following raw materials in parts by mass:

[0075] TDI type polyurethane prepolymer 96 parts

[0076] PAPI type polyurethane prepolymer 3 parts

[0077] 1 part of zirconia micropowder with particle size ≤10μm;

[0078] The component B is made from the following raw materials in parts by mass:

[0079]

[0080]

[0081] A method for preparing the polyurethane elastomer polishing material described in this embodiment, comprising the following steps:

[0082] 1) Preparation of component A: put 96 parts by mass of TDI type polyurethane prepolymer, 3 parts by mass of PAPI type polyurethane prepolymer and 1 part by mass of zirconia micropowder with a particle size of ≤10 μm in a mixer , stir and mix evenly at room temperature, store in a nitrogen-filled seal to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com