A resin cbn grinding wheel for processing saw blade base

A grinding wheel and substrate technology, applied in metal processing equipment, manufacturing tools, abrasives, etc., can solve problems such as increasing the operating cost of manufacturers, and achieve the effects of reducing production difficulty and operating cost, improving packaging performance, and reasonable composition of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

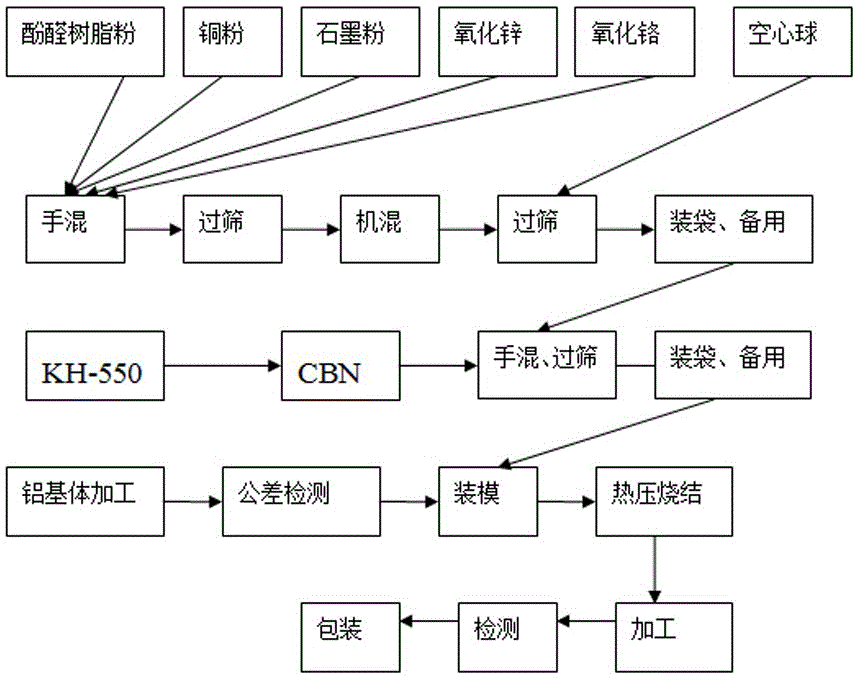

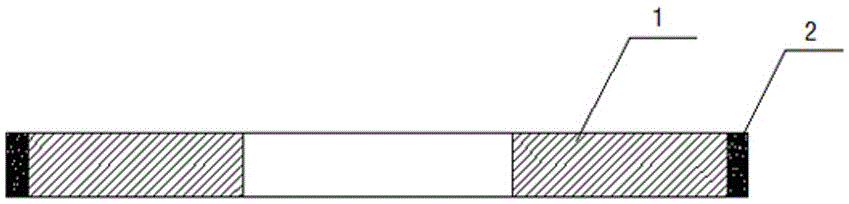

[0031] Embodiment one: see attached figure 1 As shown, the method of preparing the resin CBN grinding wheel for processing the saw blade matrix includes: mixing materials, loading molds, hot pressing, sintering and hardening, and then processing the hardened grinding wheel molded body to the shape and size required by the drawing, according to the superhard grinding wheel After passing the national standard inspection, it will be put into storage.

[0032] The raw material composition and weight percentage of the abrasive layer are: 20% CBN abrasive, 30% phenolic resin powder, 5% sodium hexafluoroaluminate, 10% electrolytic copper powder, 15% zinc oxide, 10% chromium oxide, and 5% graphite powder , Alumina hollow ball 5%.

[0033] The average particle diameter of the phenolic resin powder is 40 μm, the average particle diameter of sodium hexafluoroaluminate is 45 μm, the average particle diameter of electrolytic copper powder is 20 μm, the average particle diameter of metal ...

Embodiment 2

[0040] Embodiment two: the technology of preparing emery wheel is identical with embodiment one, specifically:

[0041]The raw material composition and weight percentage of the abrasive layer are: CBN abrasive 25%, phenolic resin powder 33%, sodium hexafluoroaluminate 5%, electrolytic copper powder 12%, zinc oxide 8%, chromium oxide 7%, graphite powder 4% , Aluminum oxide hollow ball 6%; CBN abrasive contains 25% nickel-plated CBN abrasive and 75% non-nickel-plated CBN abrasive.

[0042] The average particle diameter of the phenolic resin powder is 40 μm, the average particle diameter of sodium hexafluoroaluminate is 45 μm, the average particle diameter of electrolytic copper powder is 20 μm, the average particle diameter of metal oxide is 45 μm, the average particle diameter of graphite powder The diameter of alumina hollow spheres is 10 μm, and the average particle size of alumina hollow spheres is 30 μm.

[0043] (1) Mixing: Mechanically mix resin powder, electrolytic copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com