Large-pore CBN grinding wheel for machining sliding vanes of compressor

A technology of compressors and large pores, which is applied in metal processing equipment, manufacturing tools, abrasives, etc., can solve the problems of poor wear resistance of resin bonds, affecting the service life of grinding wheels, and roughness that cannot meet the standard, so as to reduce the number of dressings, The effect of improving production efficiency and reducing the frequency of manual wheel replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

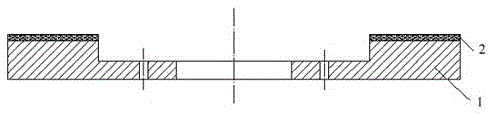

[0024] see figure 1 Shown, a kind of large hole CBN emery wheel that is used for processing compressor slide vane, comprises substrate 1 and abrasive material layer 2, and the raw material composition and volume percentage of described abrasive material layer are, CBN abrasive material 20%, phenolic resin powder 48%, graphite Powder 12%, electrolytic copper powder 10%, alumina hollow ball 10%; among them, the CBN abrasive grain size is 200 / 230, and the crystal form is polycrystalline resin abrasive with nickel plating 30%.

[0025] The average particle size of the phenolic resin powder is 64 μm, the average particle size of the graphite powder is 65 μm, the average particle size of the electrolytic copper powder is 65 μm, and the average particle size of the aluminum oxide hollow spheres is 1.5-2.0 mm.

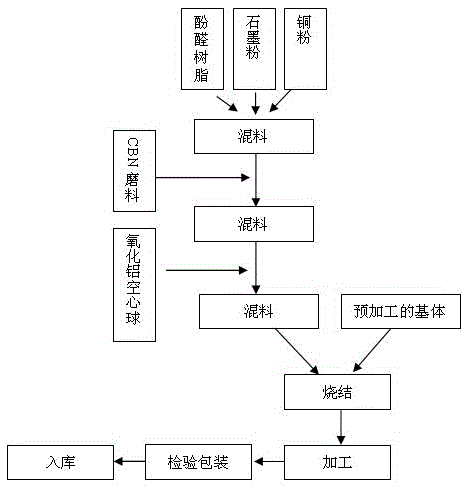

[0026] see figure 2 Shown, be used for the preparation method of the large hole CBN emery wheel of processing compressor vane, specifically comprise the following steps:

...

Embodiment 2

[0034] see figure 1 Shown, a kind of large hole CBN emery wheel that is used for processing compressor slide vane, comprises substrate 1 and abrasive material layer 2, and the raw material composition and volume percentage of described abrasive material layer are, CBN abrasive material 15%, phenolic resin powder 48%, graphite 13% copper powder, 9% electrolytic copper powder, and 15% aluminum oxide hollow ball; among them, the CBN abrasive particle size is 200 / 230, and the crystal form is polycrystalline resin abrasive with 30% nickel plating.

[0035] The average particle size of the phenolic resin powder is 64 μm, the average particle size of the graphite powder is 65 μm, the average particle size of the electrolytic copper powder is 65 μm, and the average particle size of the aluminum oxide hollow spheres is 1.5-2.0 mm.

[0036] see figure 2 Shown, be used for the preparation method of the large hole CBN emery wheel of processing compressor vane, specifically comprise the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com