A superabrasive grinding wheel for machining heterogeneous metal components

A technology of superabrasives and heterogeneous metals, applied in the direction of abrasives, bonded grinding wheels, metal processing equipment, etc., can solve problems such as inability to process at the same time, achieve the effects of improving production efficiency, reducing the number of dressing times, and eliminating the phenomenon of workpiece burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

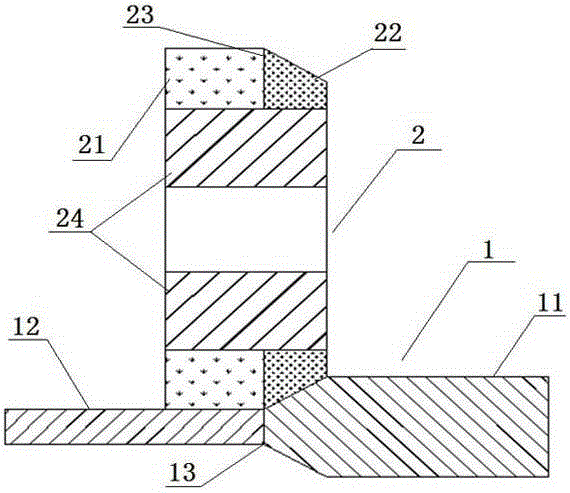

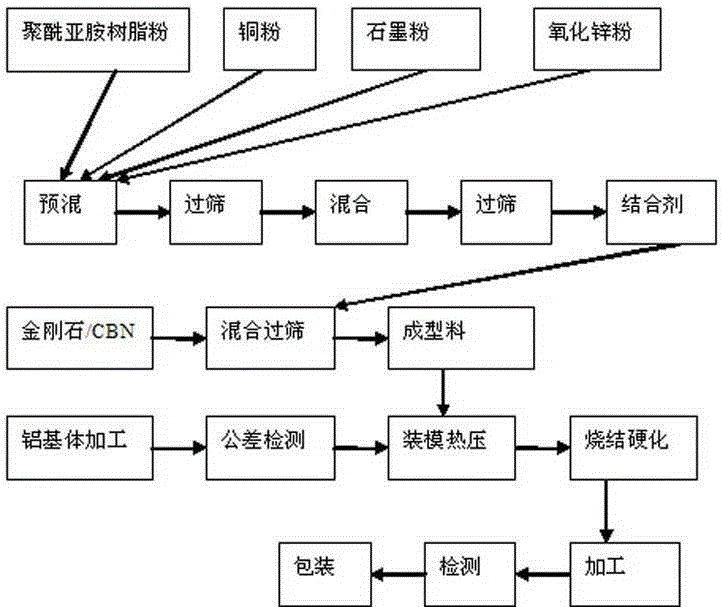

[0041] Embodiment one: see attached figure 1 As shown, the method for preparing a superabrasive grinding wheel for processing heterogeneous metal components includes: mixing materials, loading molds, hot pressing, sintering and hardening, and then processing the hardened grinding wheel molded body to the shape and size required by the drawing, according to the super abrasive Hard grinding wheels are put into storage after passing the national standard inspection.

[0042] (1) Mixing: Weigh 20 parts of polyimide resin powder, 60 parts of copper powder, 5 parts of graphite powder and 15 parts of zinc oxide according to the weight ratio, pre-mix by hand, pass through a 60# sieve, and then put Mix mechanically in a ball mill. A drum made of ceramic material is selected, the ball-to-material ratio is 2:1, the rotating speed of the drum is 60 rpm, and the mixing time is set to 5 hours. After the mixing is completed, pass through the 200# sieve to obtain the binder; according to t...

Embodiment 2

[0045] Embodiment two: the technology of preparing emery wheel is identical with embodiment one, specifically:

[0046] (1) Mixing: Weigh according to the weight ratio: 30 parts of polyimide resin powder, 55 parts of copper powder, 5 parts of graphite powder, 10 parts of zinc oxide, pre-mixed by hand, passed through a 60# sieve, and then put into Mix mechanically in a ball mill. A drum made of ceramic material is selected, the ball-to-material ratio is 2:1, the rotating speed of the drum is 60 rpm, and the mixing time is set to 5 hours. After the mixing is completed, pass through a 200# sieve to obtain the binder; according to the density of the binder and the volume of the grinding wheel, mix 70 parts of the binder and 30 parts of diamond, mix 70 parts of the binder and 30 parts of cubic boron nitride (CBN) , cross 120# screen cloth respectively, obtain diamond forming material, CBN forming material; The surfaces of described diamond and CBN are nickel-plated;

[0047] (2) ...

Embodiment 3

[0049] Embodiment three: the technology of preparing emery wheel is identical with embodiment one, specifically:

[0050] (1) Mixing: Weigh according to weight ratio: 50 parts of polyimide resin powder, 40 parts of copper powder, 6 parts of graphite powder, 5 parts of zinc oxide, pre-mixed by hand, passed through a 60# sieve, and then put into Mix mechanically in a ball mill. A drum made of ceramic material is selected, the ball-to-material ratio is 2:1, the rotating speed of the drum is 60 rpm, and the mixing time is set to 5 hours. After the mixing is completed, pass through the 200# sieve to obtain the binder; according to the density of the binder and the volume of the grinding wheel, mix 80 parts of the binder and 20 parts of diamond, mix 80 parts of the binder and 20 parts of cubic boron nitride (CBN) , cross 200# sieve respectively to obtain diamond molding material and CBN molding material; the surfaces of the diamond and CBN are all nickel-plated.

[0051] (2) Mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com