Lubricating oil oil quality online detector

A lubricating oil and detector technology, applied in the field of mechanical lubrication, can solve the problems of narrow application range, many monitoring units, failure to monitor lubricating oil viscosity, wear particle concentration and transparency, etc., to reduce blindness and simple system installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

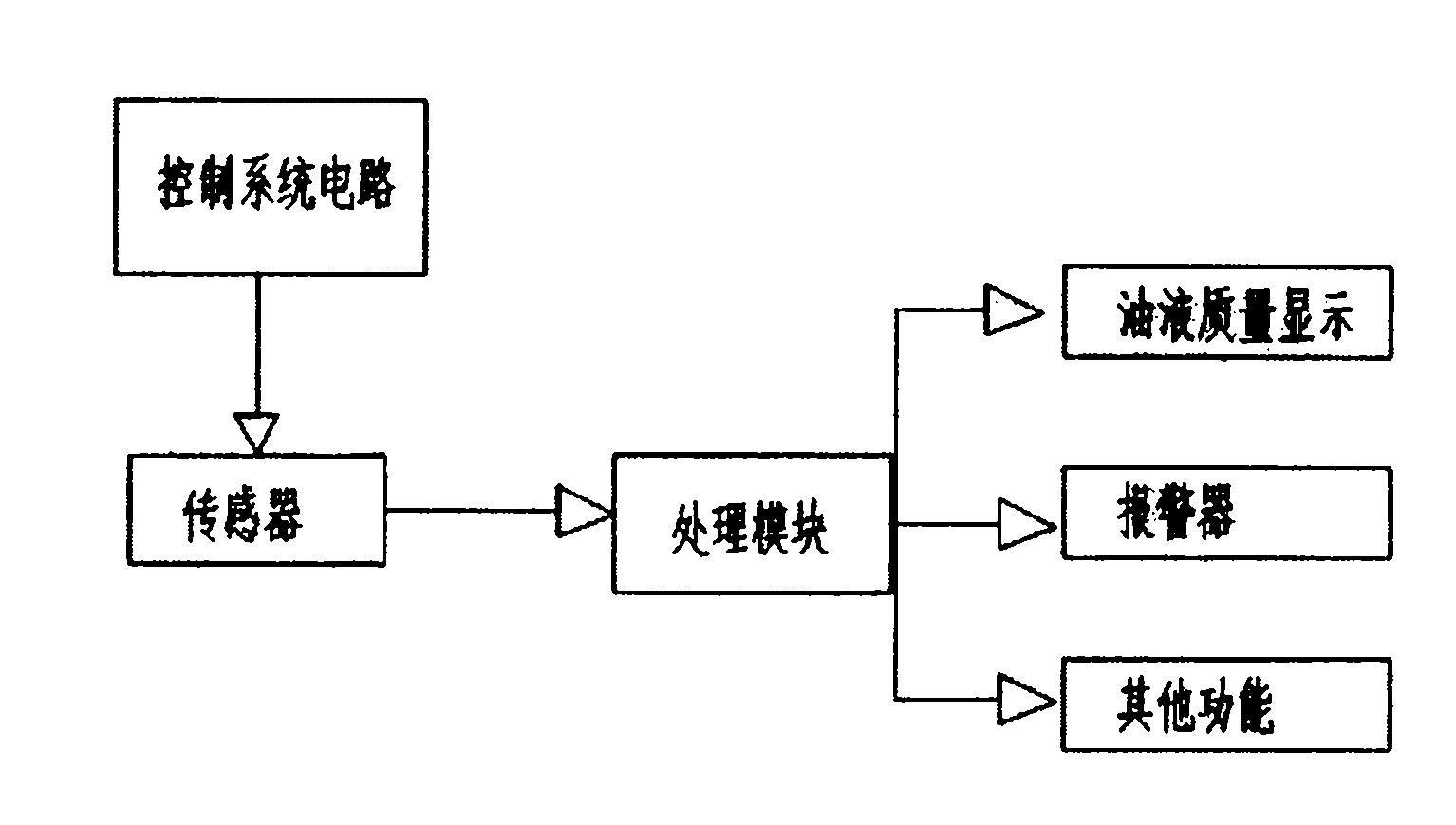

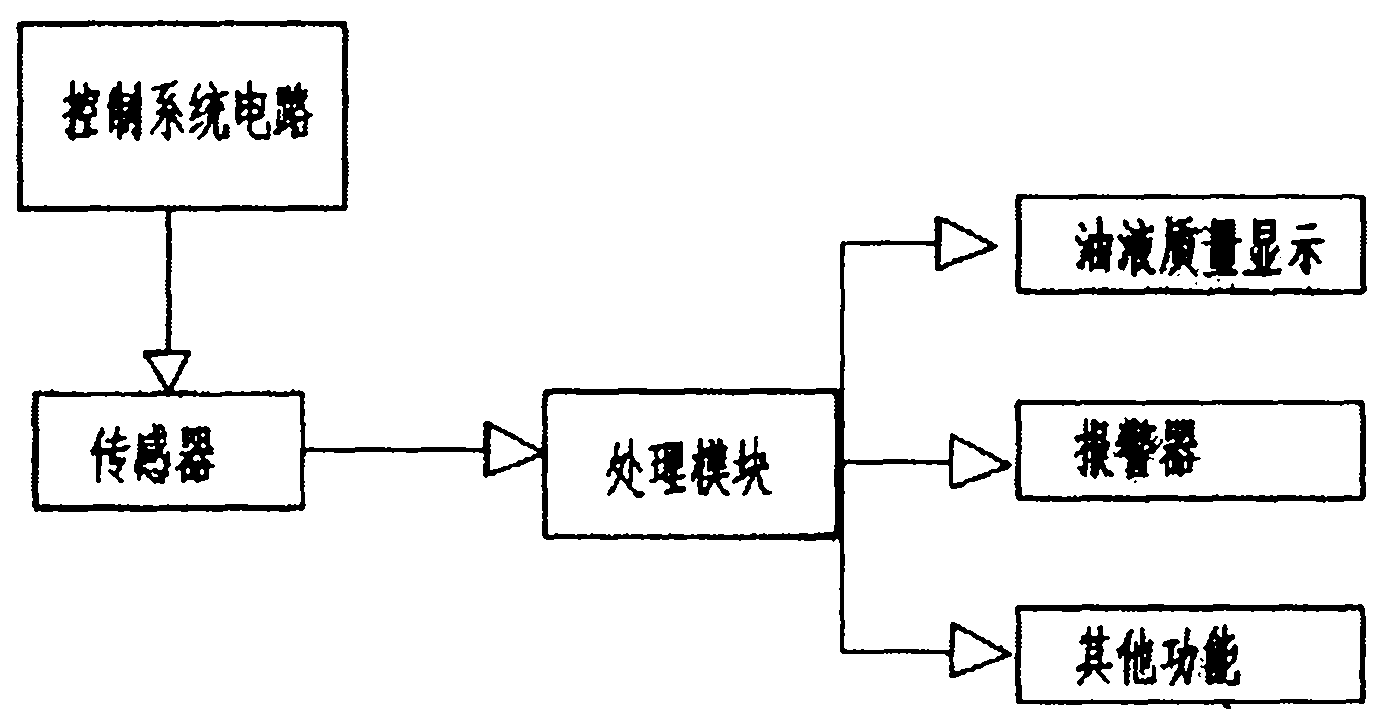

[0013] Such as figure 1 As shown, an online detector for lubricating oil quality includes a system control circuit, a sensor and a processing module, the system control circuit controls the sensor, and the sensor and the processing module perform information transmission, and the processing module includes system data processing software, set It has oil quality standard value, can store data, and also has a display terminal and alarm equipment.

[0014] The sensor adopts a fluid characteristic sensor, a plunger probe with a diameter of 35mm, a length of <100mm, a working voltage of 0-5V, and a working temperature of -20 to 120°C. It has a universal interface, high sealing and sensitivity, and is installed on the gear The oil tank is in contact ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com