Abrasive tool and method of making the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

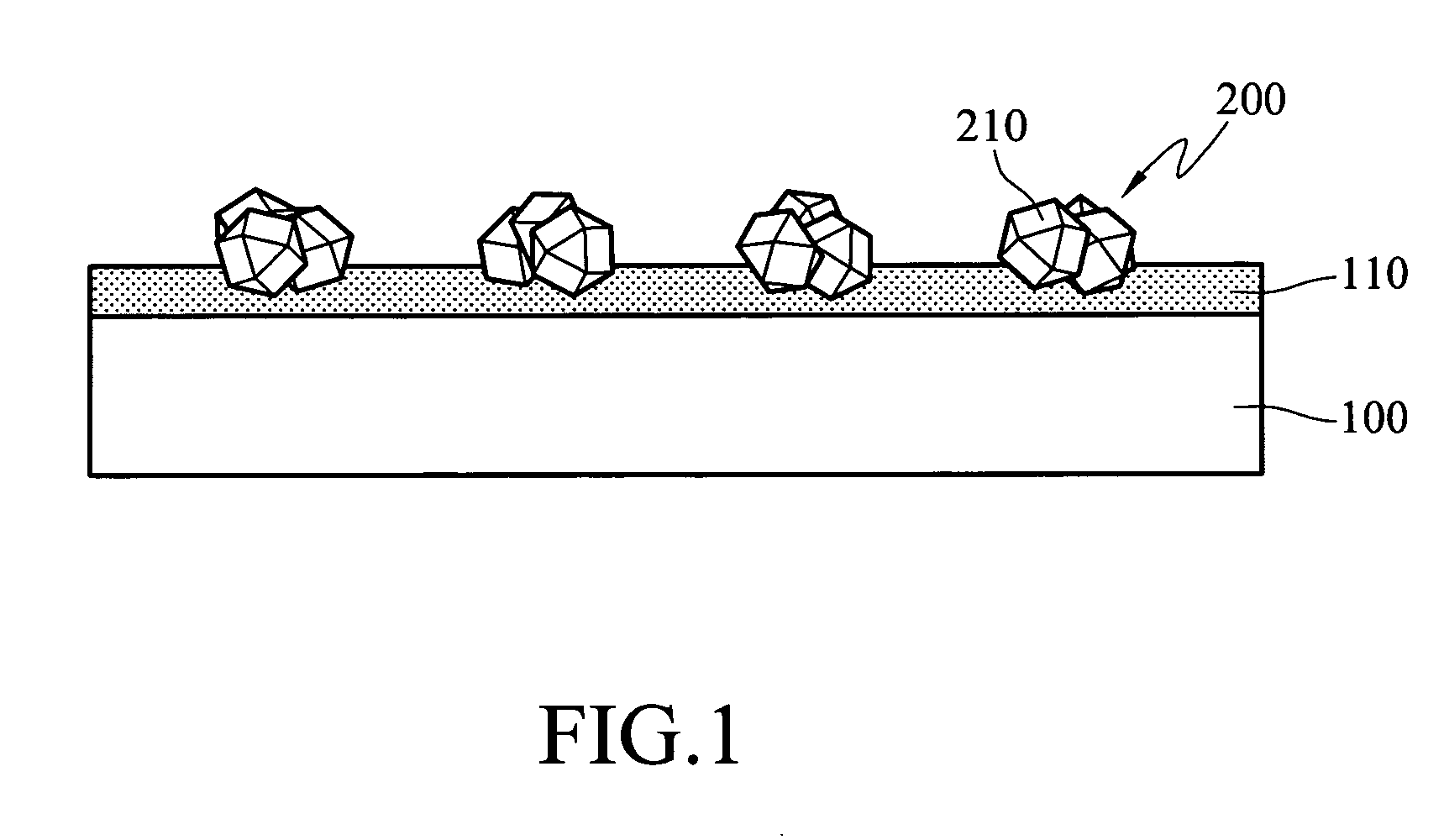

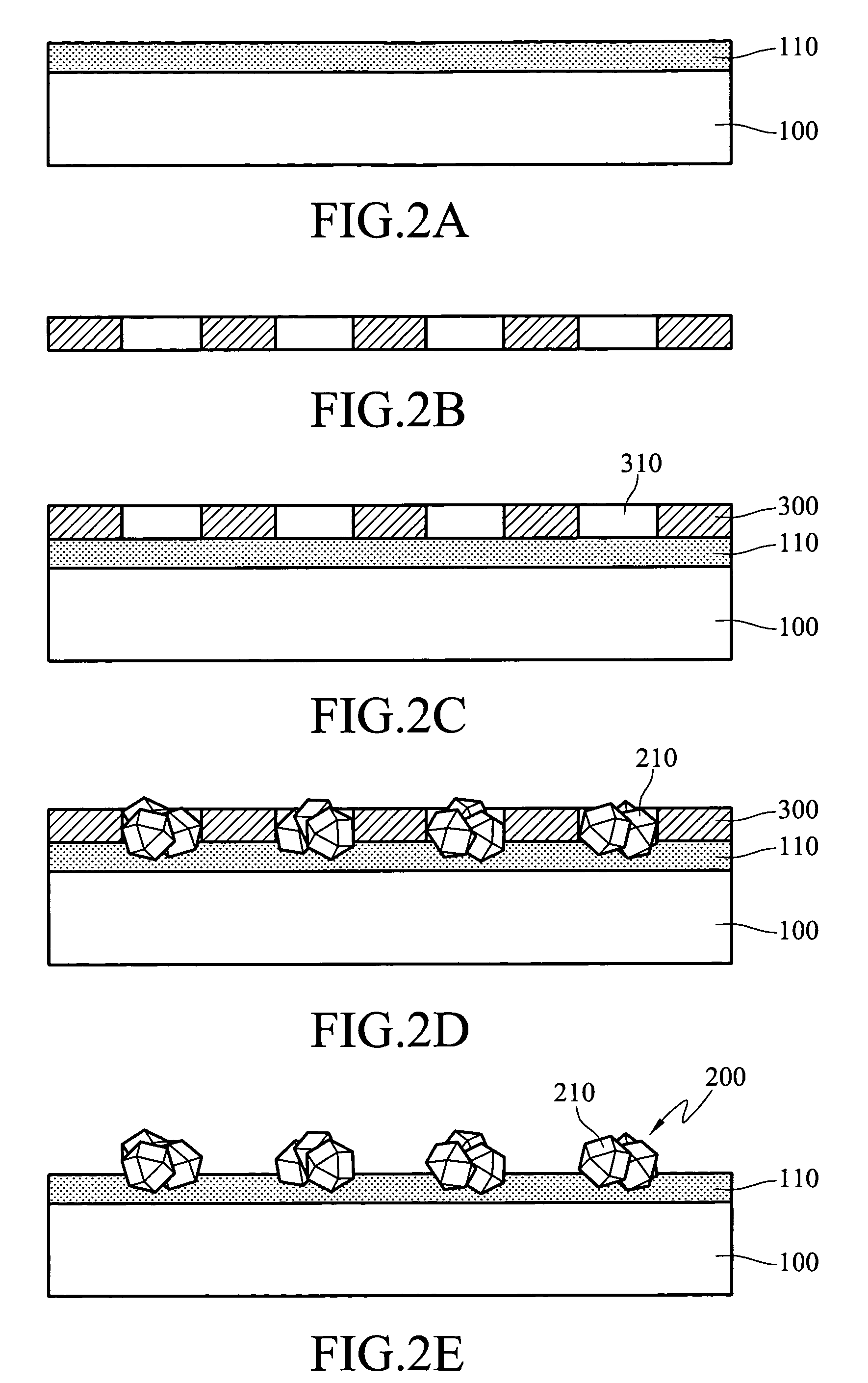

[0022] As described above, the disclosed abrasive tool and the method of making the same can increase the cutting rate of the abrasive tool and solve the problem of falling abrasive particles due to non-uniform pressures. The disclosed abrasive tool thus has a better polishing homogeneity and longer lifetime. The invention is particularly of use for making the polish pad conditioner / dresser in high-precision CMP. Therefore, we explain the structure of the polish pad conditioner / dresser that utilizes the invention and the method of making the same. We use diamond particles as the abrasive particles.

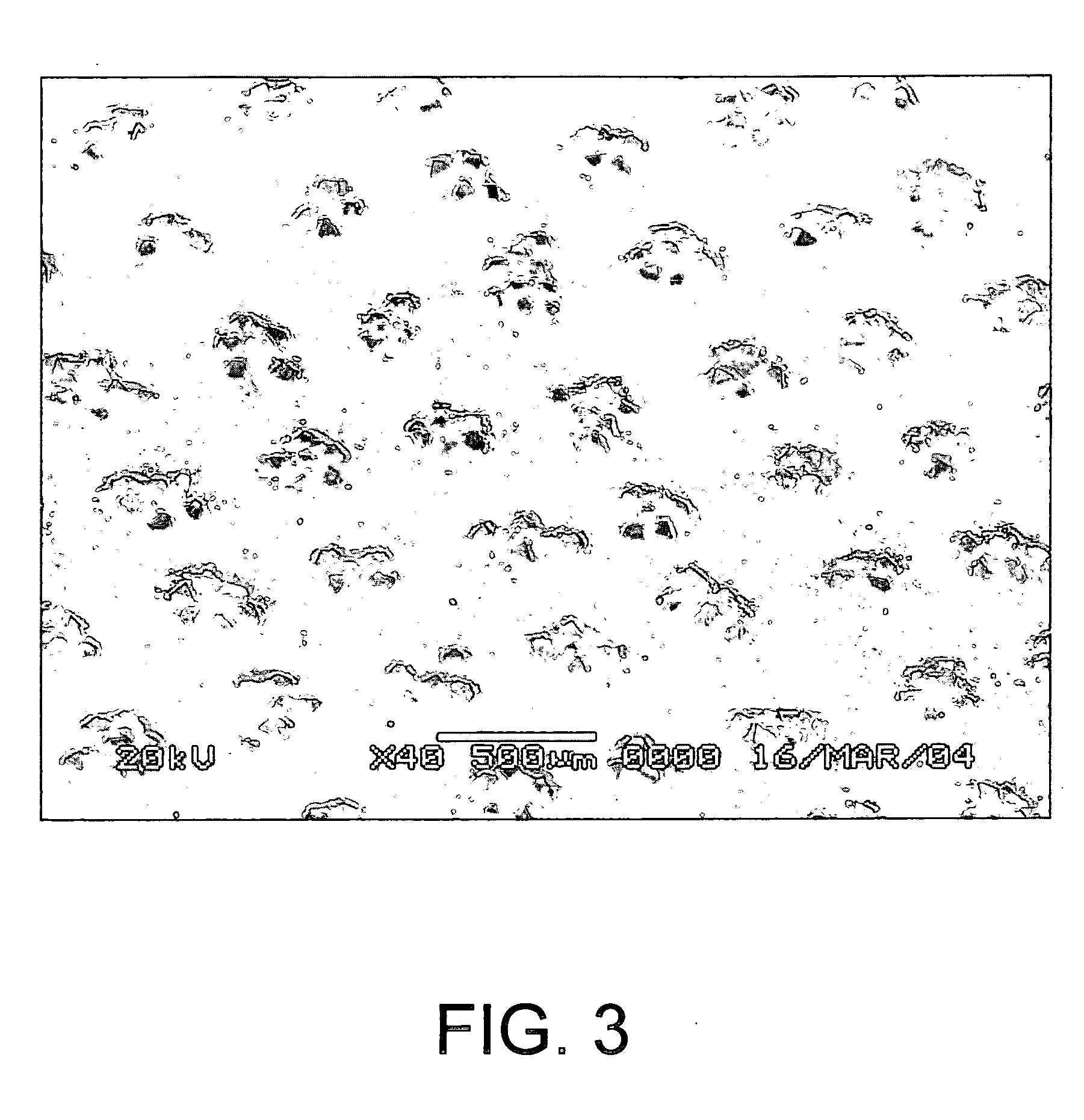

[0023] With reference to FIG. 1, it is seen that the polish pad conditioner / dresser in this embodiment includes: a substrate 100, a plurality of diamond particle groups 200, and a bonding layer 110. Each diamond particle group 200 consists of several diamond particles 210 grouped together. The diamond particle groups 200 are disposed in a regular pattern on the surface of the substrate 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com