Urea-formaldehyde adhesive and preparation method thereof

A technology of adhesives and urea-formaldehyde adhesives, applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem of reducing the bonding strength of wood-based panels, increasing the cost of adhesives, and reducing the check strength and other problems, to achieve the effects of easy promotion and use, improvement of quality and performance, and simple preparation

Inactive Publication Date: 2015-05-06

金思思

View PDF3 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these technical solutions all have defects. (1) Although the use of low molar ratio modified urea-formaldehyde adhesive can effectively reduce the formaldehyde emission of wood-based panel products, the check strength of the product is often reduced; Adding a formaldehyde scavenger to the urea-formaldehyde adhesive for boards effectively reduces the release of free formaldehyde, but at the same time reduces the bonding strength of the wood-based panels, and greatly increases the cost of the adhesive; (3) Post-processing of the wood-based panels processing, but the equipment cost of post-processing is often greater

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

[0030] Embodiment 3 is the best implementation mode.

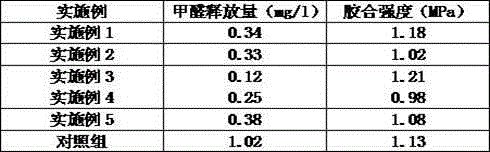

[0031] Performance Testing:

[0032] The urea-formaldehyde glue adhesive prepared in Examples 1-5 was used in plywood, and then the release amount and bonding strength of formaldehyde in the plywood were measured.

[0033] The control group used common commercially available urea-formaldehyde adhesives.

[0034]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Login to View More

Abstract

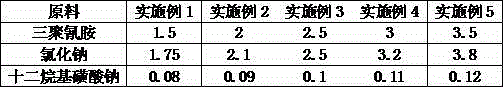

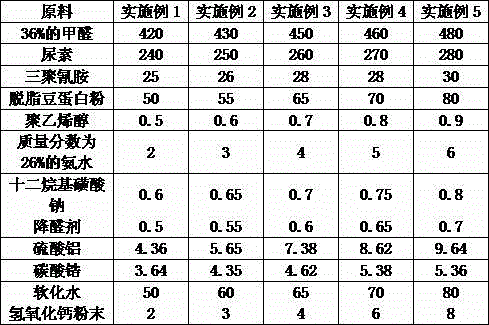

The invention relates to the technical field of urea-formaldehyde adhesives, and particularly relates to a urea-formaldehyde adhesive additive for artificial boards and a preparation method thereof. The urea-formaldehyde adhesive is composed of the following components in parts by mass: 420-480 parts of 36% formaldehyde, 240-280 parts of urea, 25-30 parts of melamine, 50-80 parts of degreased bean albumen powder, 0.5-0.9 part of polyvinyl alcohol, 2-6 parts of 26 wt% ammonia water, 0.6-0.8 part of sodium dodecylsulfate, 0.5-0.7 part of aldehyde reducing agent, 8-15 parts of complexing agent, 50-80 parts of softened water and 2-8 parts of calcium hydroxide powder. The urea-formaldehyde adhesive additive lowers the amount of free formaldehyde in the urea-formaldehyde glue adhesive, enhances the quality performance of the urea-formaldehyde adhesive, increases the viscosity to some extent, and greatly improves the stability and water resistance. The urea-formaldehyde adhesive has the advantages of low cost and simple preparation process, and is convenient for popularization and use.

Description

technical field [0001] The invention relates to the technical field of urea-formaldehyde adhesives, in particular to an additive for urea-formaldehyde adhesives for wood-based panels and a preparation method thereof. Background technique [0002] Wood-based panels are boards or molded products that are made of wood or other waste wood plants, separated into various unit materials by certain mechanical processing, and checked with or without adhesives and other additives. It mainly includes three categories of products such as plywood, particleboard and fiberboard, and there are hundreds of extended products and deep-processed products. The production of wood-based panels has improved the comprehensive utilization of wood, and 1 cubic meter of wood-based panels can replace 3 to 5 cubic meters of logs. [0003] Formaldehyde is a raw material for the manufacture of synthetic resins, paints, plastics and man-made fibers, and an important raw material for the manufacture of urea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J161/30C09J11/08C09J11/06C09J11/04

Inventor 金思思

Owner 金思思

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com