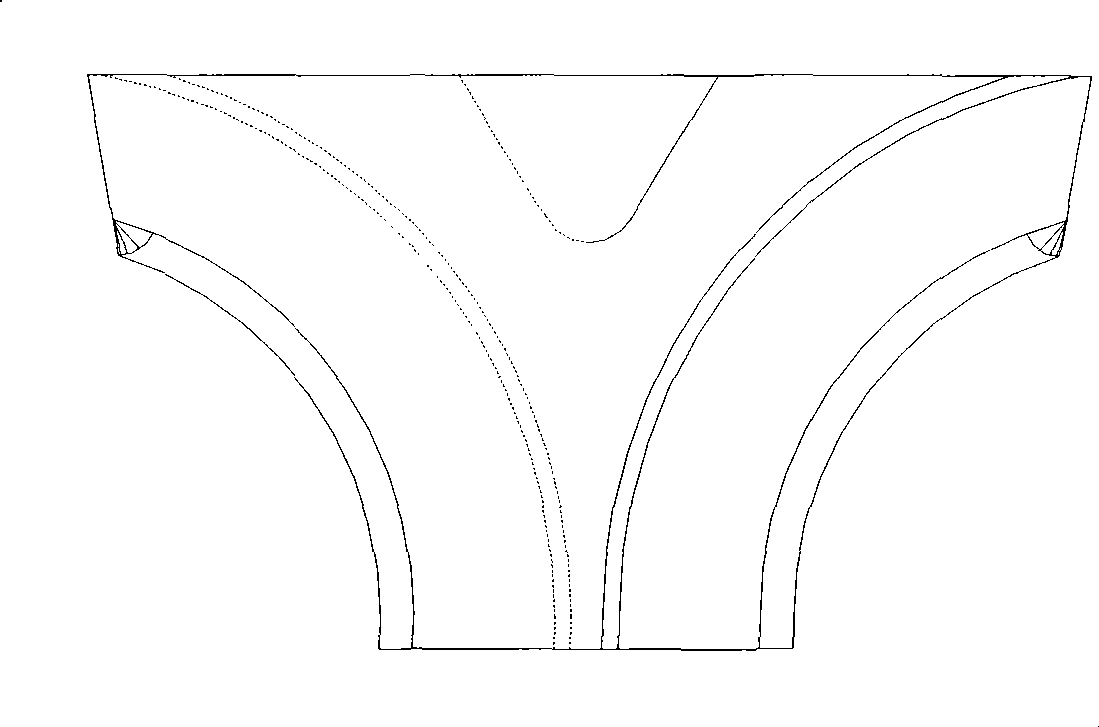

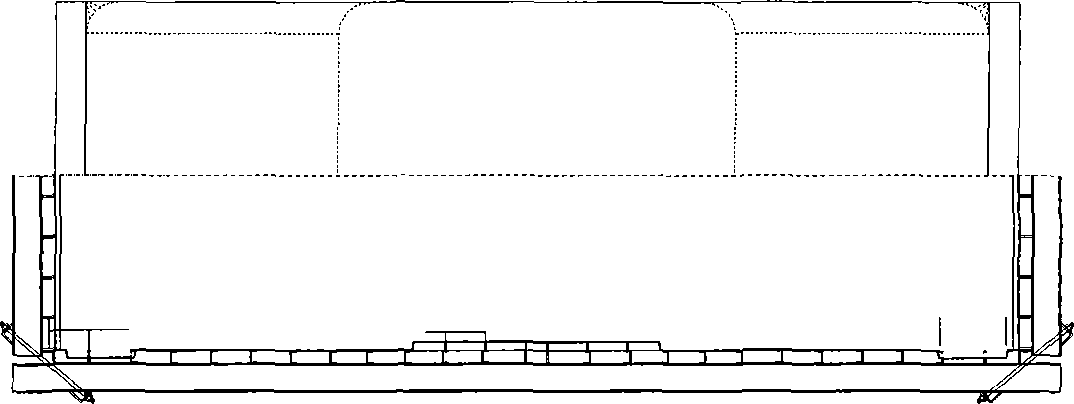

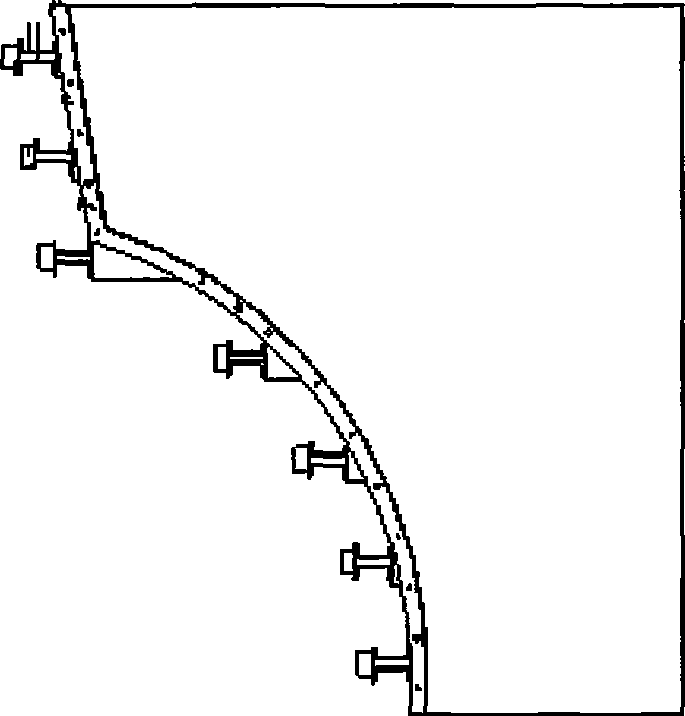

Reinforced concrete pier stud with capping beam or irregular Y-shaped reinforced concrete pier stud once-forming construction method

A reinforced concrete and construction method technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as joint unevenness, grout leakage, etc., achieve quality effect improvement, change color difference, save labor and repair materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a rail transit project in Shanghai, the pier column interface size of 98# to 138# pier is 2500MMX2200MM, and the total height of the pier column cover beam is 6M to 6.2M.

[0022] 1. Template design:

[0023] The lower straight section pier column steel mold and the upper cap beam steel mold are designed to be assembled at one time, and the straight section formwork is composed of four A.B.C.D. pieces on four sides. The upper cover beam formwork consists of four sides and two arc bottom forms which are divided into six pieces of A.B.C.D.E.F. to form the formwork. After the formwork is completed, the ground trial assembly is carried out first to ensure that the assembly size is correct with decorative convex lines, the joints are flat, and the arc connection is smooth. , Welding and grinding, smooth transition, so as to reduce the seam marks. The straight line section is 100MM-200MM below the natural soil level to set the adjustment mold to the cap, which is convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com