Adjustable ladle fixing device

A technology of fixing device and ladle, which is applied in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of increased labor intensity of operators, inability to adjust the center of gravity of the ladle, and large turning moment of the ladle. Easy to adjust, easy to flip, and reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

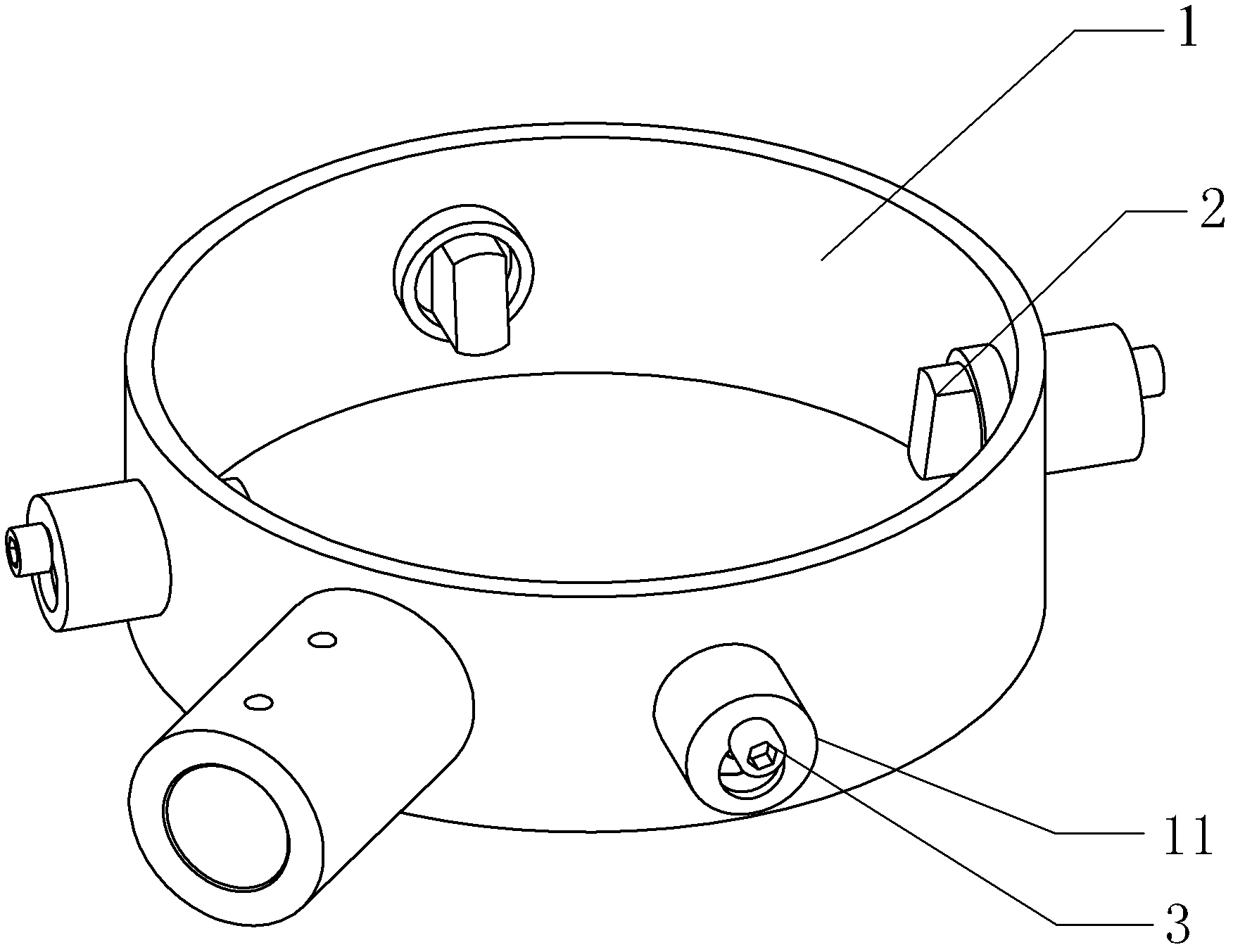

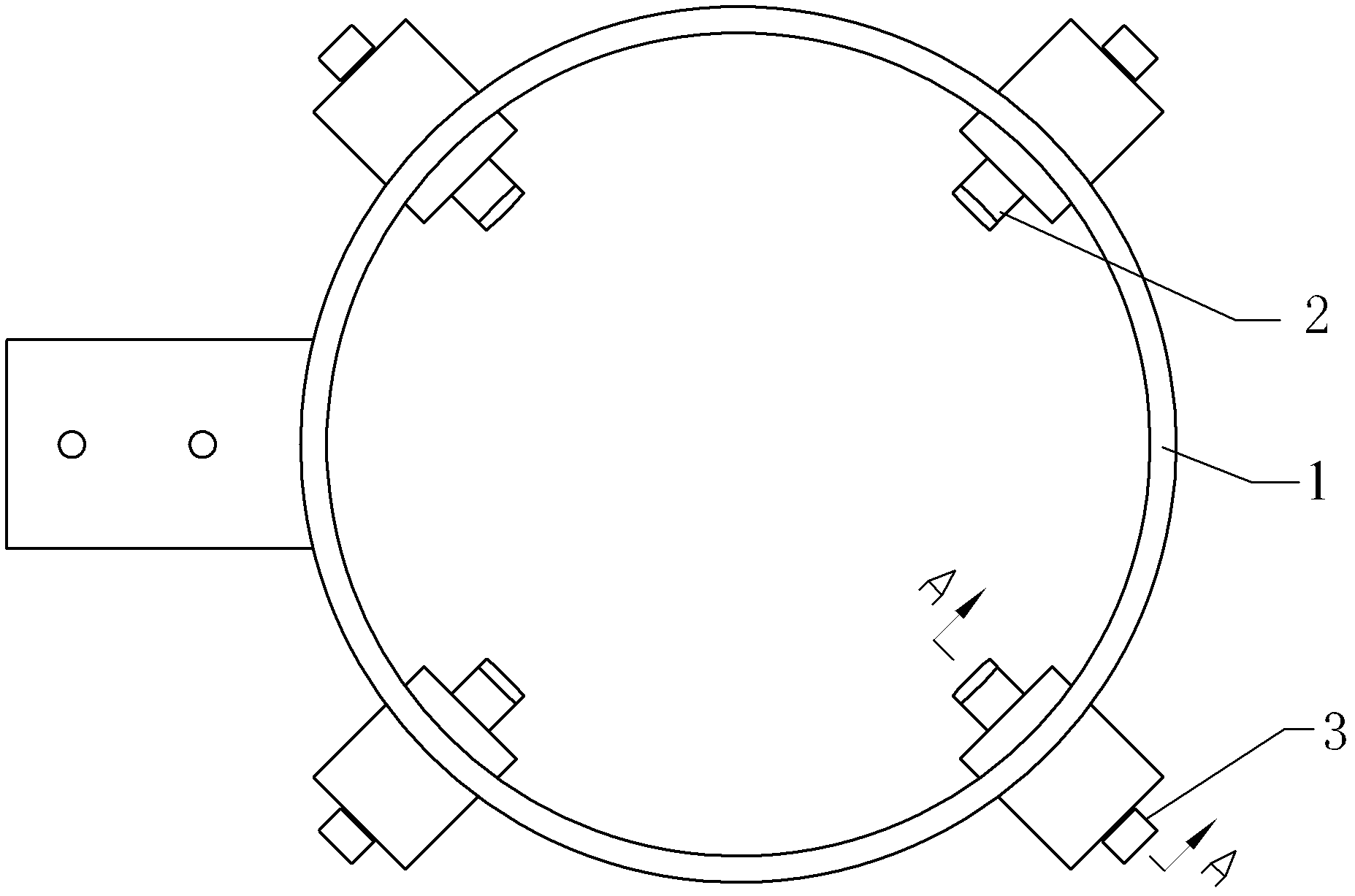

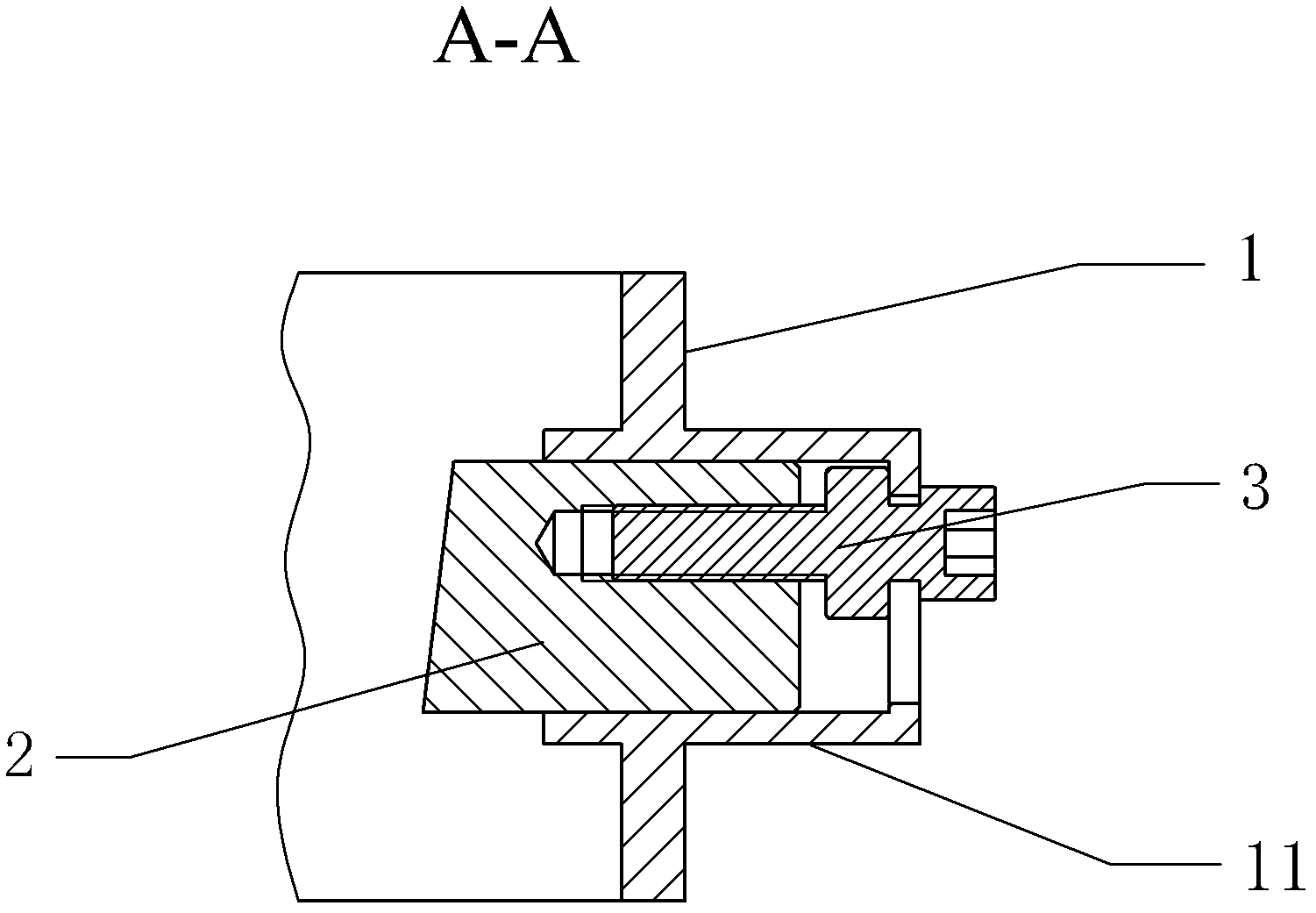

[0019] Such as figure 1 and figure 2 As shown, an adjustable ladle fixing device includes a fixing frame 1, a support rod 2 and an adjusting screw 3. In this embodiment, the fixing frame 1 is a circular fixing frame, and the fixing frame 1 is provided with a clamping end and a 4 sets of mounting holes 11, four sets of mounting holes 11 are evenly distributed on the fixed frame 1, and one set of mounting holes 11 includes a barrel-shaped outer wall fixed on the fixed frame 1 and a limiter with an eccentric through hole fixed on the outer end of the barrel-shaped outer wall. Position wall, the limit wall with the through hole is also provided with a long hole for the adjustment screw 3 to pass through; as image 3 As shown, the end of the support rod 2 close to the inner side of the fixed frame 1 is an inclined plane, the inclination angle of which is the same as the taper of the ladle, and the other end is provided with a threaded hole matching the adjusting screw 3; the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com