Hinged tailing type cylinder tailer with telescopic legs

A telescopic outrigger and trailer-type technology, which is applied in the direction of tractor-trailer combination, inclined load-carrying vehicles, motor vehicles, etc., can solve the problems of slag tank loss of control, slag tank overturning, casualties, etc., and achieve operational safety The effect of improving performance, avoiding accidents, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

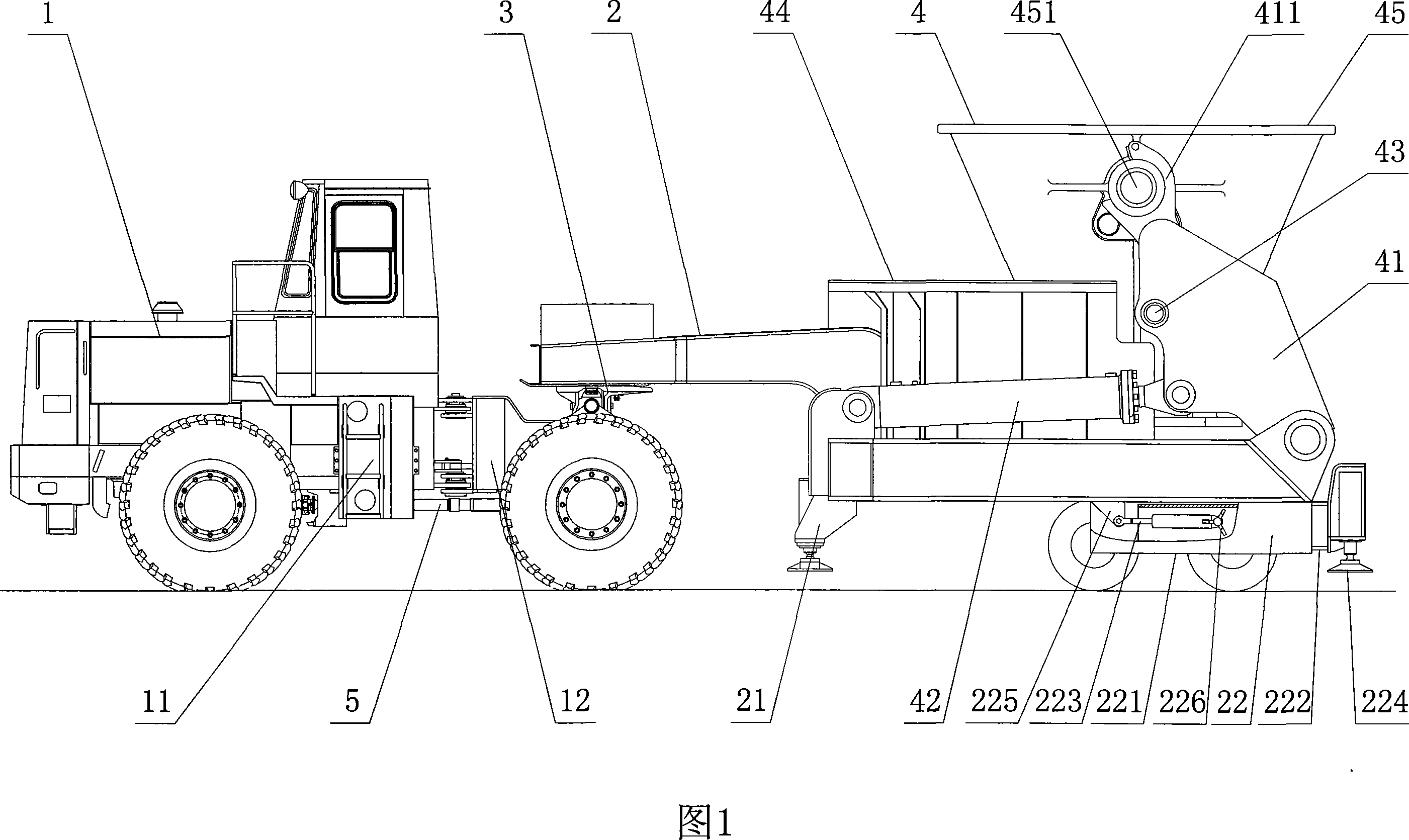

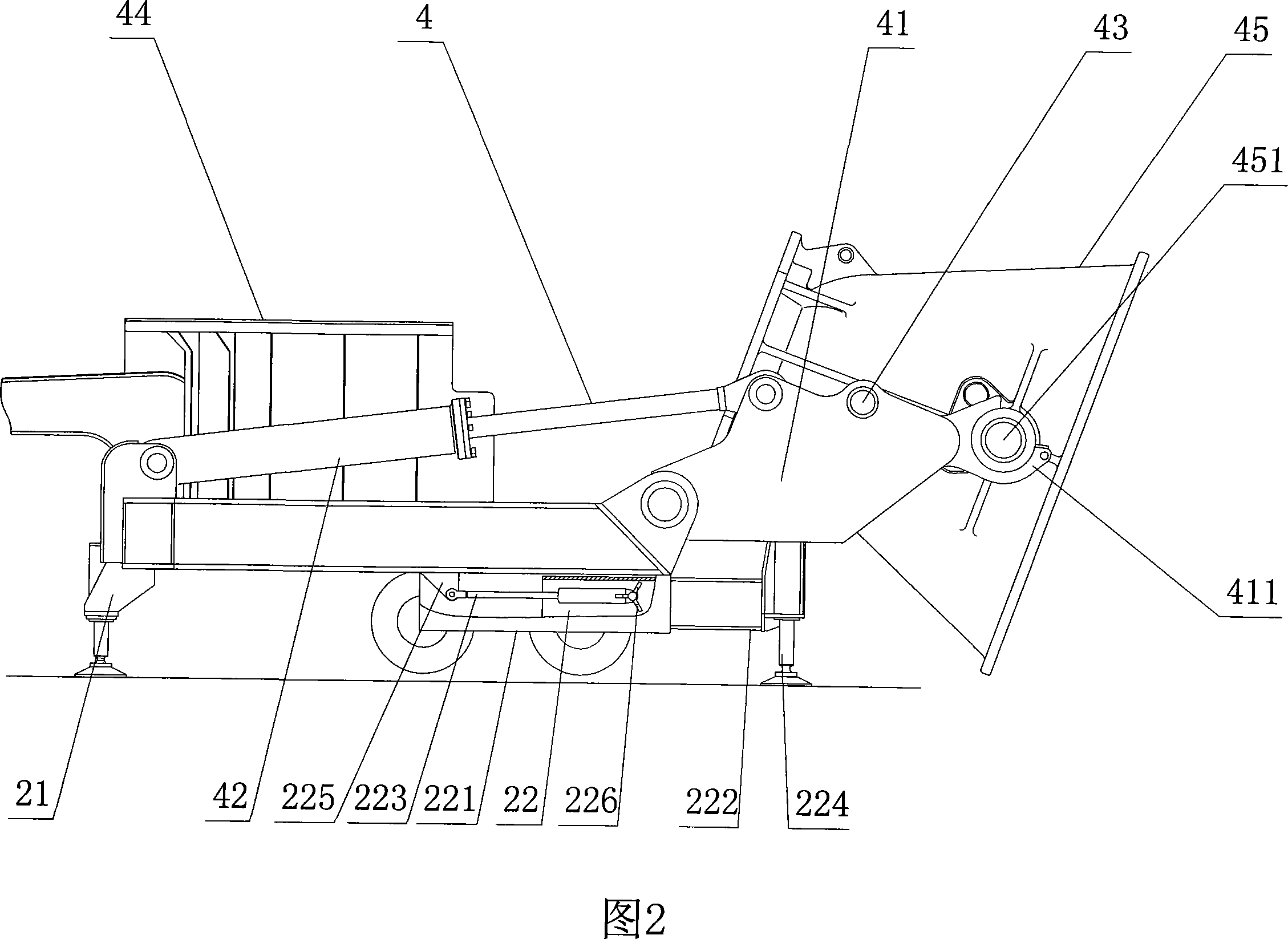

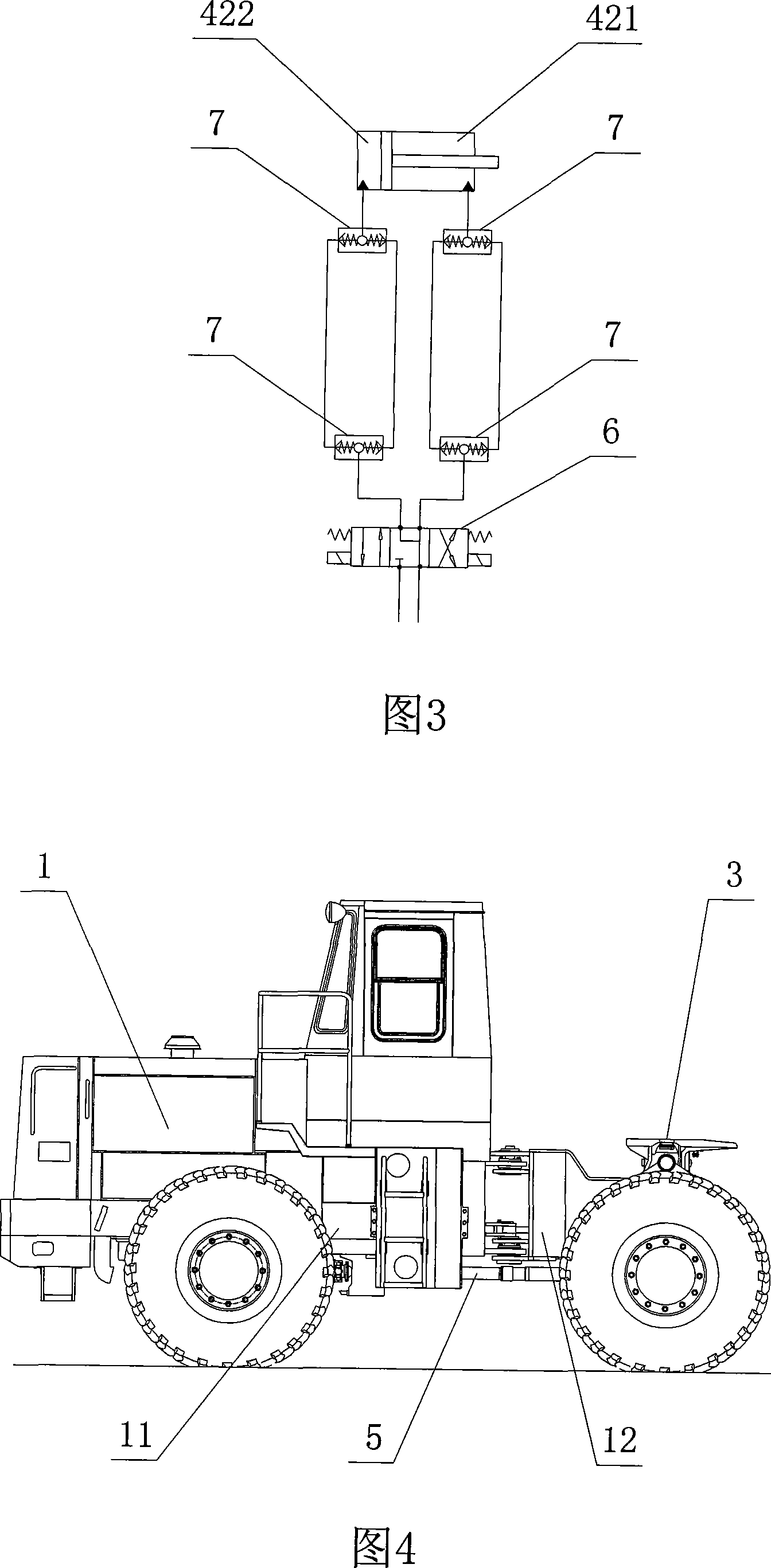

[0029] As shown in Figure 1, the articulated trailer-type tank holding vehicle with telescopic legs of the present invention includes a tractor 1, a semi-trailer 2, a saddle 3 and a tank holding mechanism 4, and the semi-trailer 2 connects with the tractor through the saddle 3. 1 is connected to the rear, and the tank holding mechanism 4 is installed on the semi-trailer 2. Front outriggers 21 are installed on both sides of the front end of the semi-trailer 2, and horizontally retractable rear outriggers 22 are installed on both sides of the rear end of the semi-trailer 2. . The horizontally expandable rear leg 22 includes a side beam 221, a box beam 222, a horizontal oil cylinder 223 and a leg 224. The side beam 221 is fixed on both sides of the rear end of the semi-trailer 2, and one end of the box beam 222 is sleeved in the side beam 221. The other end is connected with the support leg 224 , one end of the horizontal oil cylinder 223 is connected with the box girder 222 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com