Component subpackaging fixer

A technology of parts and fixtures, which is applied in the field of tooling and fixtures, can solve the problems of high labor intensity, high cost, and many devices, and achieve the effects of reducing labor intensity, facilitating support, and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

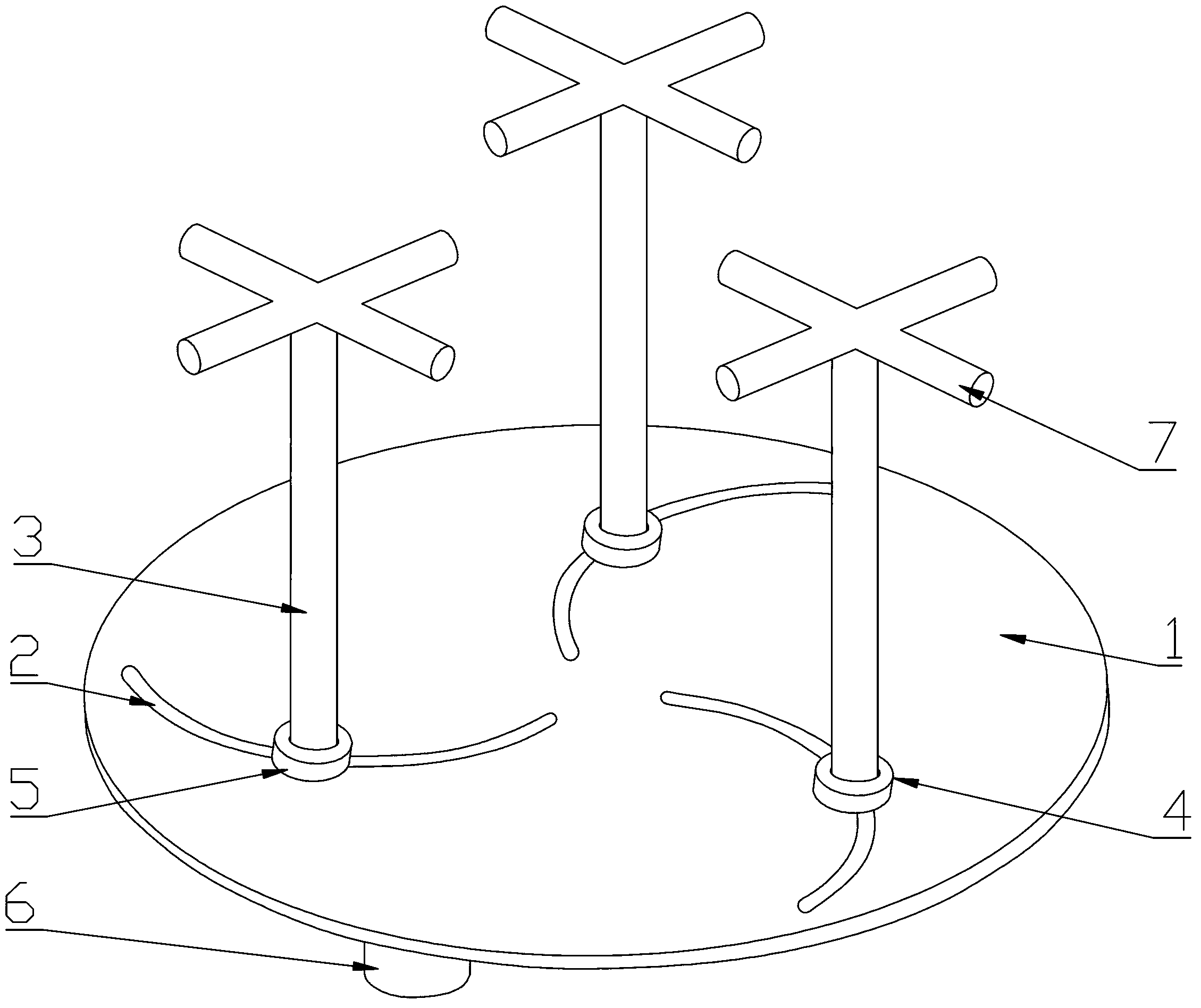

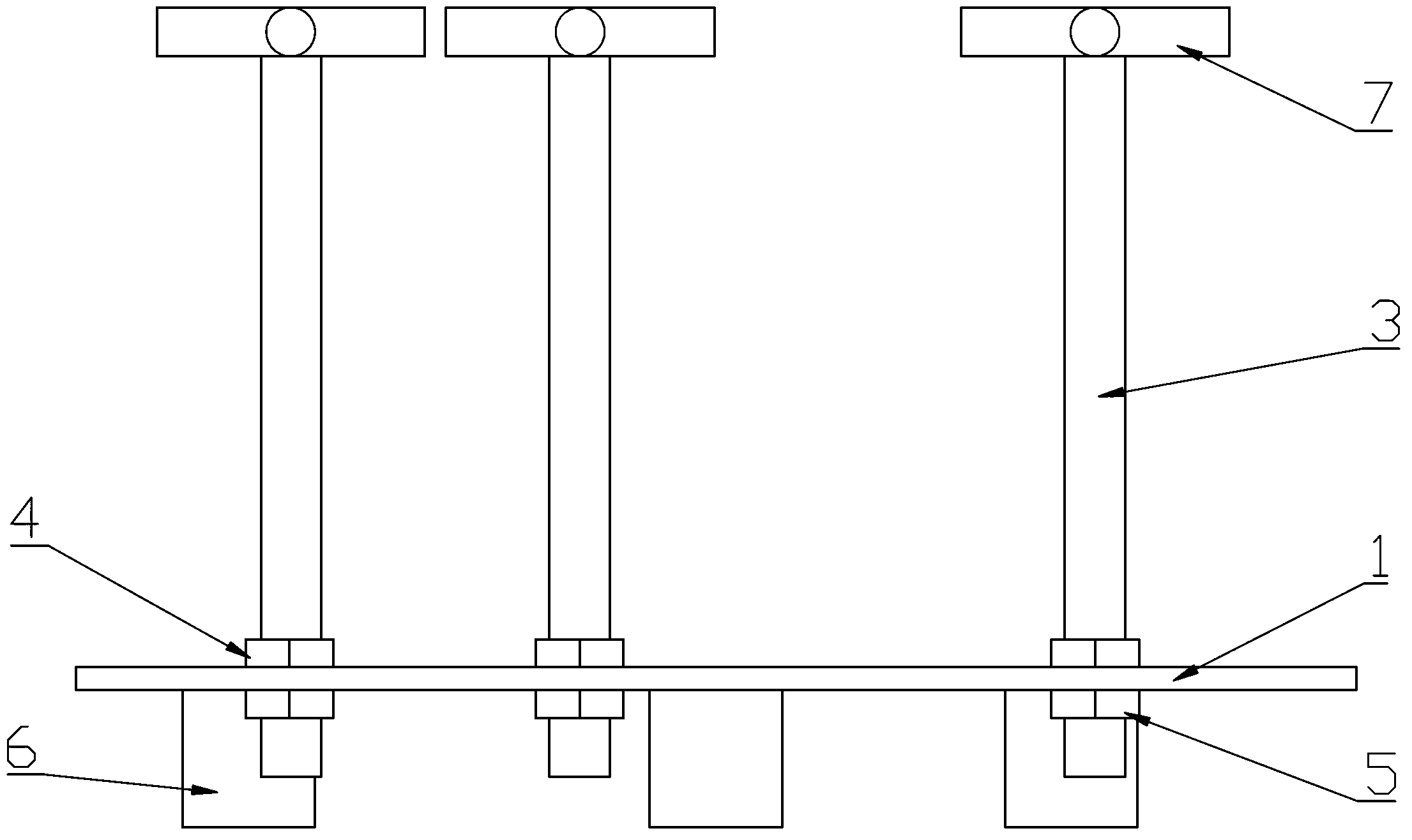

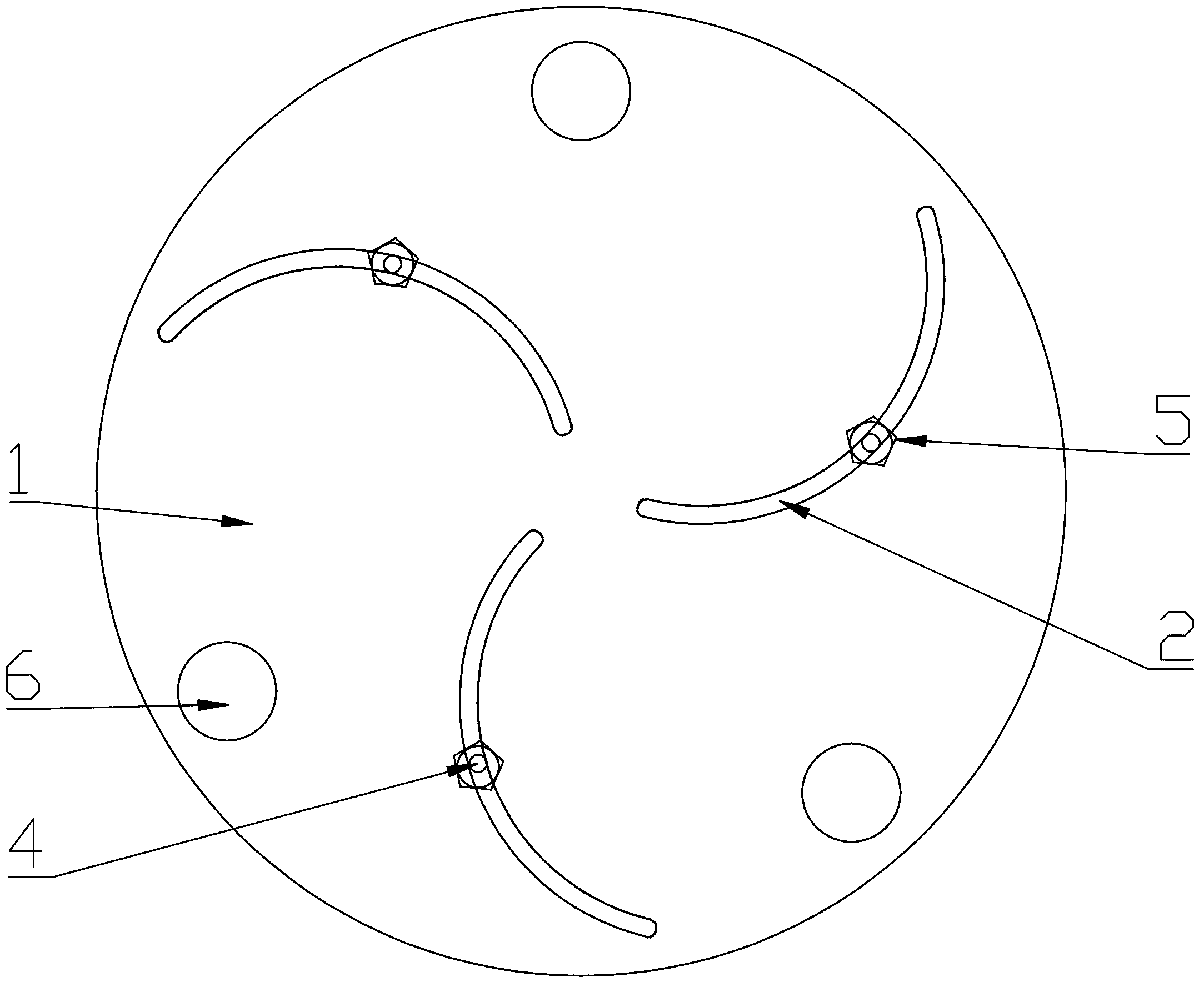

[0025] As attached to the manual figure 1 , 2 , shown in 3, a kind of parts subpackage fixer, comprises subpackage platform 1 and three struts 3, and brace bar 3 is a straight bar and is vertical with subpackage platform 1, and subpackage platform 1 is a circular plate, subpackage The platform 1 is provided with three arc-shaped grooves 2 that pass through the sub-packaging platform 1. The arc-shaped grooves 2 are "C"-shaped grooves. The three arc-shaped grooves 2 are distributed in a clockwise spiral along the center of the sub-packaging platform 1. The arrangement of the plurality of arc-shaped grooves 2 in the scheme is the same as that of the impeller blades. The positions of the struts 3 correspond to the positions of the arc-shaped grooves 2. The groove width of the arc-shaped grooves 2 is larger than the diameter of the struts 3. The struts One end of 3 extends into the corresponding arc-shaped groove 2 and cooperates with the sub-packing table 1 in clearance. Each str...

Embodiment 2

[0028] As attached to the manual Figure 4 As shown, the scheme includes two arc-shaped grooves 2 and two struts 3, the arc-shaped grooves 2 are "C"-shaped grooves, the two arc-shaped grooves 2 are distributed in an "X" shape, and the two struts 3 are connected. , others remain unchanged as in Example 1.

[0029] As attached to the manual Figure 5 As shown, the arc-shaped groove 2 in the above scheme can also be an "S"-shaped groove, the two arc-shaped grooves 2 are distributed in an "X" shape, and the two struts 3 are connected, and the others remain unchanged as in Embodiment 1.

Embodiment 3

[0031] As attached to the manual Image 6 As shown, the scheme includes two arc-shaped grooves 2 and two struts 3, the arc-shaped grooves 2 are "C"-shaped grooves, and the two arc-shaped grooves 2 are symmetrically distributed along the center line of the sub-packing table 1, and others such as Embodiment 1 remains unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com