Method for preparing high-density concrete with uniform aggregate and aggregate thereof

A high-density concrete and aggregate technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of large fluctuations in the uniform distribution rate of aggregates and difficulties in conveying high-density concrete, and achieve uniform radiation protection capabilities , Aggregate subsidence is reduced and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

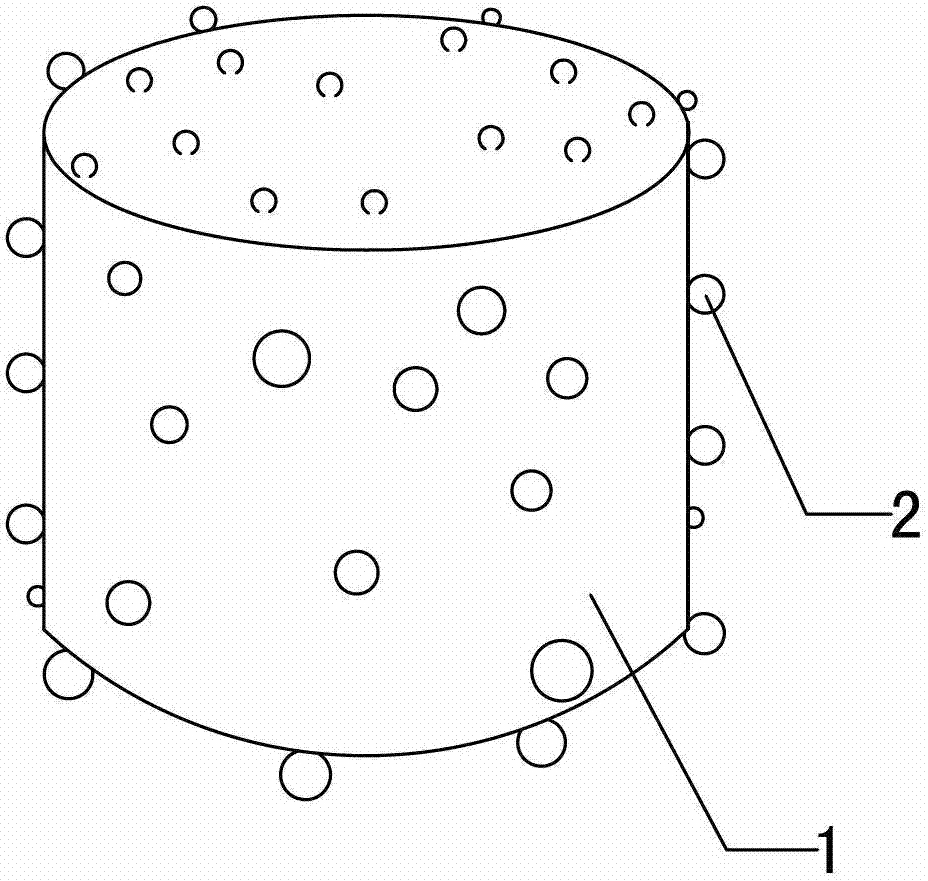

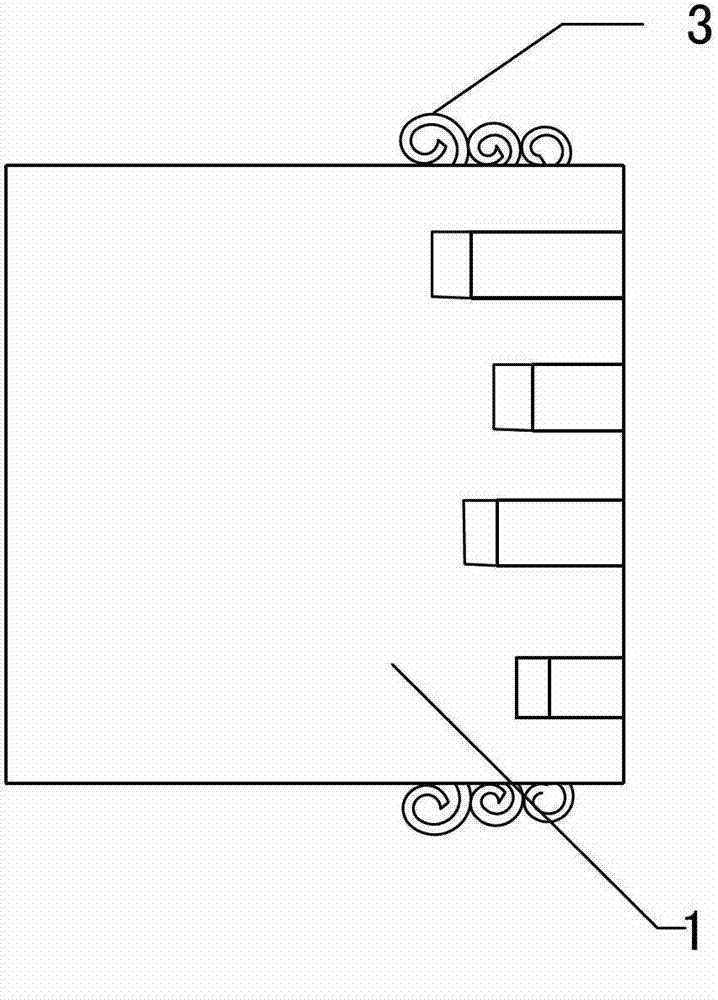

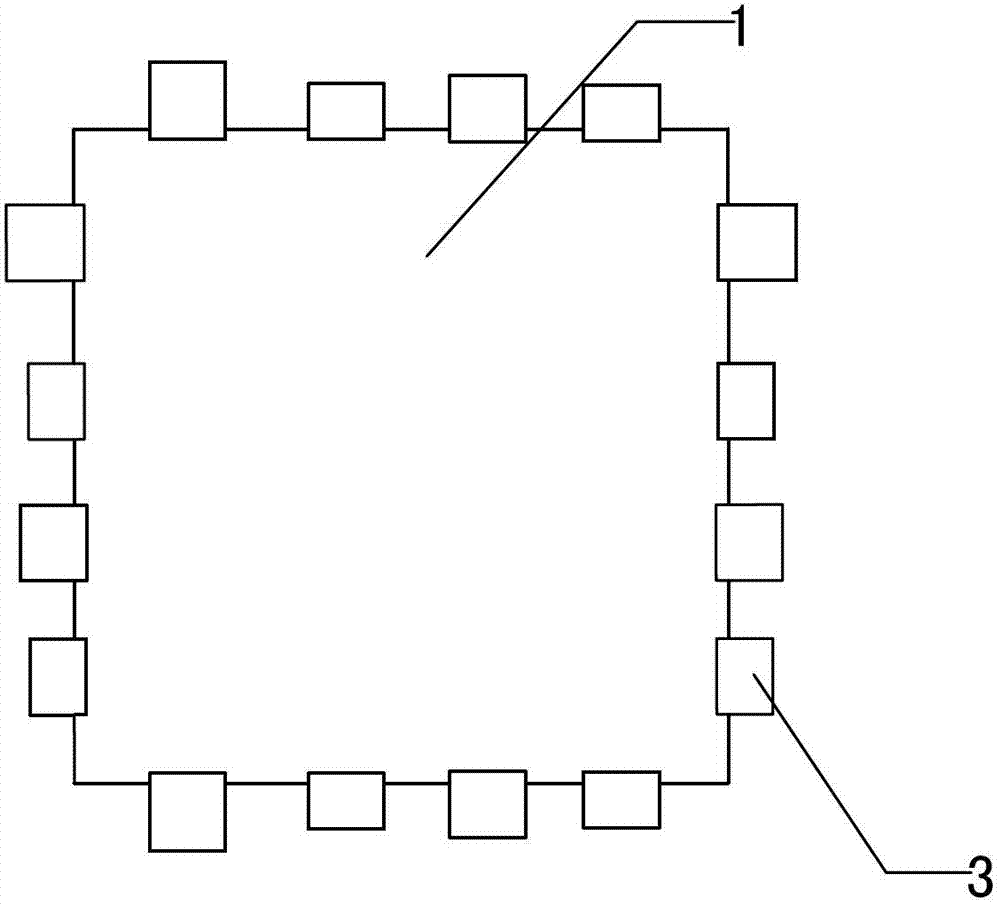

Embodiment 1

[0041] When preparing concrete with a slump of 80mm according to the current specification, the cylindrical aggregate in the concrete with a slump of 80mm presents the attitude of the smallest horizontal plane, and the axis of the cylinder is parallel to the gravity line. The density of the prepared concrete is 4900kg / m 3 ;The density of iron columnar aggregate 1 is 7800kg / m 3 , the column height is 13mm, and the diameter of the horizontal section is D z =16mm, 15% of the surface of the prism is stuck with particles with diameters ranging from d=1.6 to 4.8mm, and the cross-section is S g =3.14×64mm 2 , the equivalent section of the aggregate is S d =7800 / 4900×3.14×8 2 mm 2 , the profile diameter of the secondary aggregate is d 2 =0.25×16mm, the diameter of the tertiary aggregate profile is d 3 =0.4×4mm, the rest are omitted.

[0042] Experimental estimation formula, average particle diameter, disturbed area S r =3.14K×(8+3.2+3.2) 2 mm 2 . In this embodiment, the nu...

Embodiment 2

[0049] When preparing concrete with a slump of 80mm according to the current specification, the cylindrical aggregate in the concrete with a slump of 80mm presents the attitude of the smallest horizontal plane, and the axis of the cylinder is parallel to the gravity line. The density of the prepared concrete is 4600kg / m 3 ;The density of iron columnar aggregate 1 is 7800kg / m 3 , the column height is 16mm, and the diameter of the horizontal section is D z =20mm, 5% of the surface of the prism is stuck with particles with diameters ranging from d=2 to 6mm, and the cross-section is S g =3.14×10 2 mm 2 , the equivalent section of the aggregate is S d =7800 / 4600×3.14×10 2 mm 2 , the profile diameter of the secondary aggregate is d 2 =0.4×20mm, the diameter of the tertiary aggregate profile is d 3 =0.2×8mm, the rest are omitted.

[0050] Experimental estimation formula, average particle diameter, disturbed area S r =3.14K×(10+4+4) 2 mm 2 . In this embodiment, the number...

Embodiment 3

[0057] When the concrete with a slump of 80mm is used according to the current specification, the cylindrical aggregate in the concrete with a slump of 80mm presents the attitude of the smallest horizontal plane, and the axis of the cylinder is parallel to the gravity line. The density of the prepared concrete is 6200kg / m 3 ;The density of lead columnar aggregate 1 is 11340kg / m 3 , the column height is 12.8mm, and the diameter of the horizontal section is D z =16mm, 20% of the surface of the prism is stuck with particles with diameters ranging from d=1.6mm to 4.8mm, and the cross section is S g =3.14×8 2 mm 2 , the equivalent section of the aggregate is S d =11340 / 6200×3.14×8 2 mm 2 , the profile diameter of the secondary aggregate is d 2 =0.25×16mm, the diameter of the tertiary aggregate profile is d 3 =0.3×4mm, the rest are omitted.

[0058] Experimental estimation formula, average particle diameter, disturbed area S r =3.14K×(8+3.2+3.2) 2 mm 2 . In this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com