Hydraulic crane of underground transfer rail

A hydraulic and crane technology, used in cranes and other directions, can solve the problems of small working range, large car body size, and not very wide working track.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

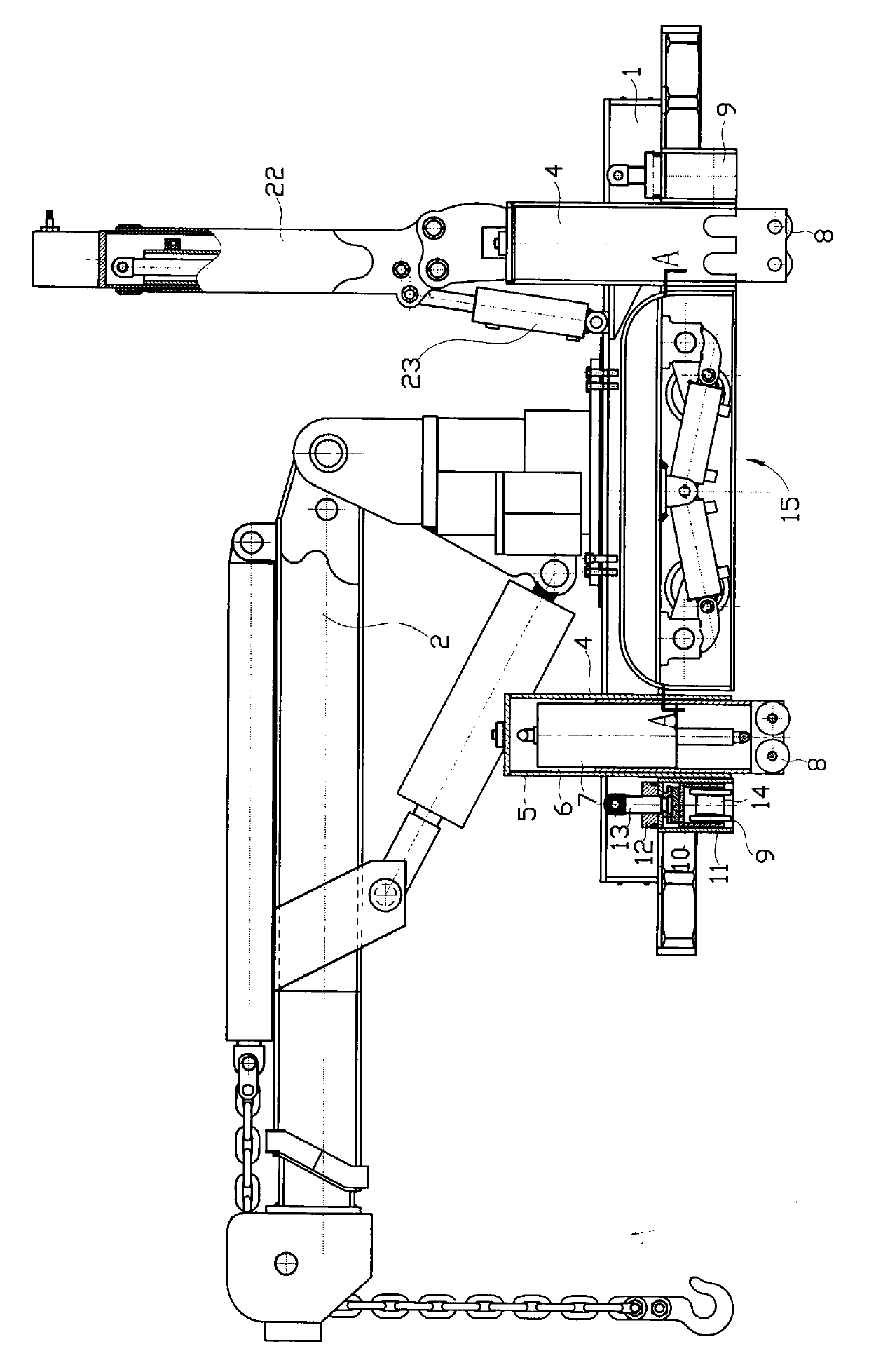

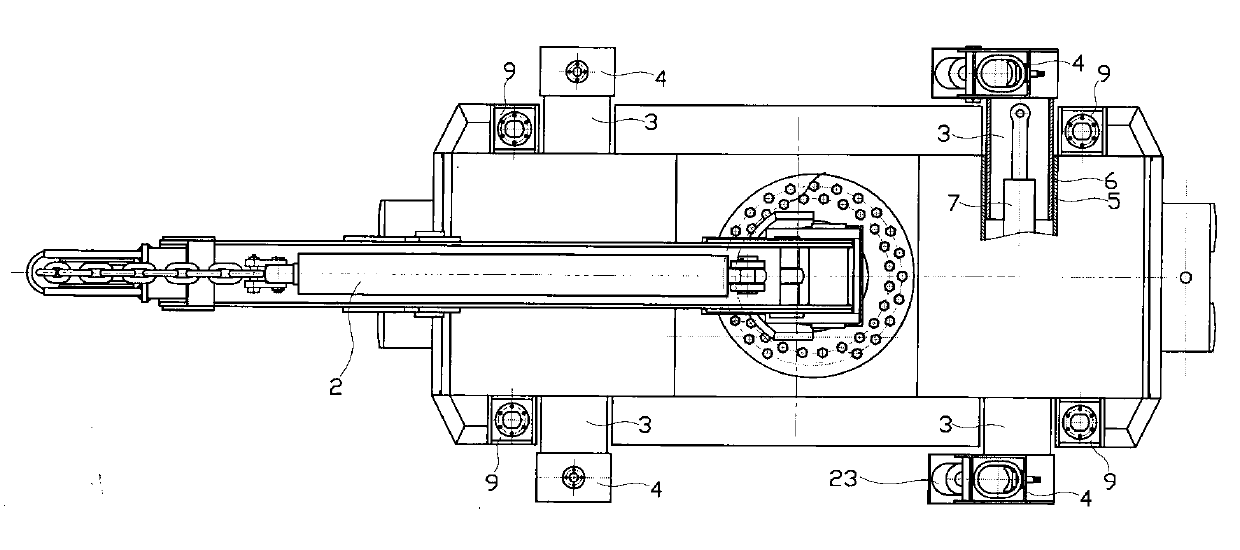

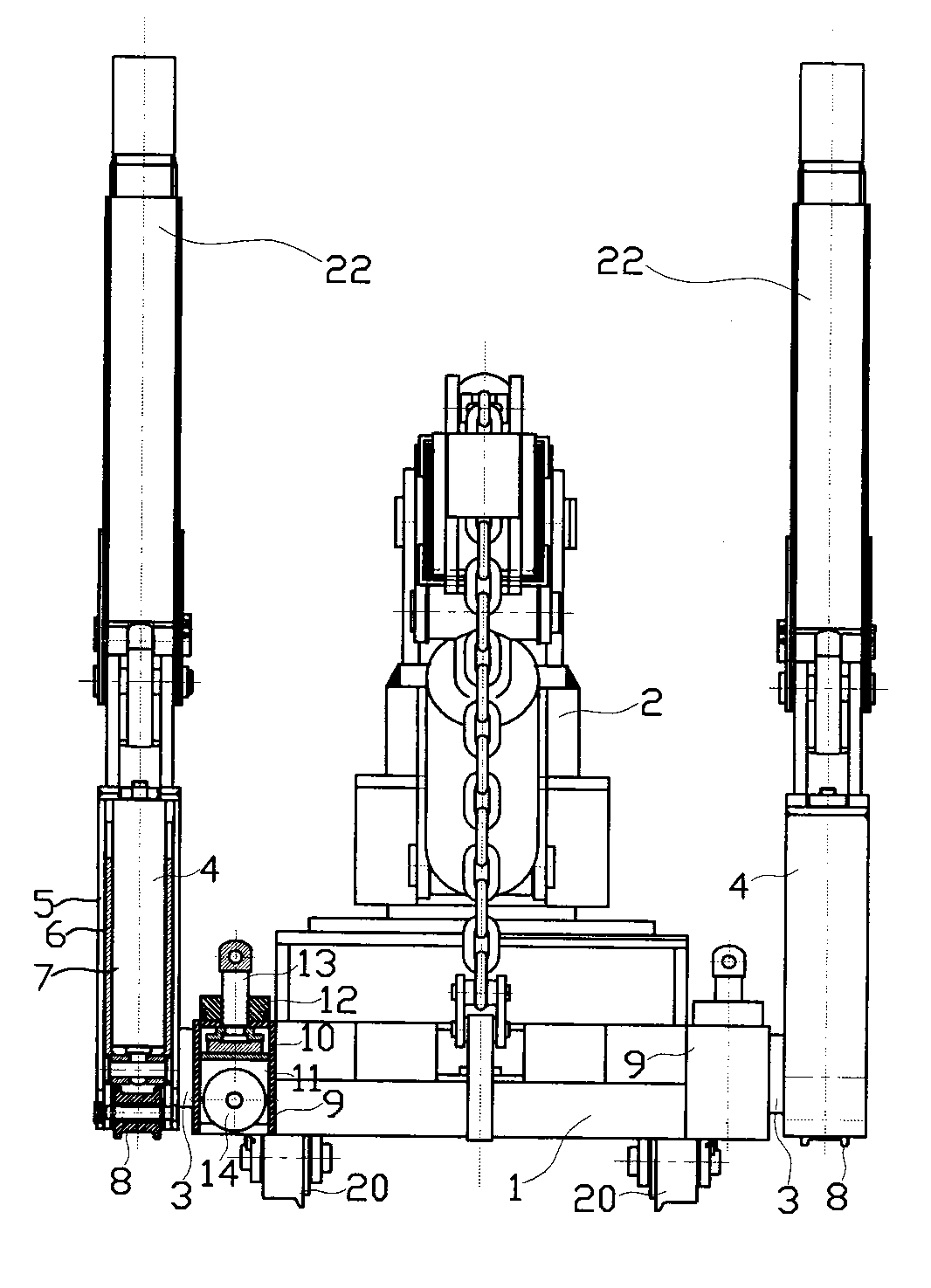

[0022] Figure 1~Figure 5 Among them, the underground track-changing hydraulic crane has a rectangular flat frame 1, a hydraulic lifting frame 2 is arranged in the middle above the flat frame, and the front and rear parts of the left and right sides of the flat frame are respectively connected with lateral hydraulic telescopic arms 3. The outer end of the hydraulic telescopic arm is connected with the downward hydraulic telescopic arm 4 perpendicular to the vehicle frame plate, and the lateral hydraulic telescopic arm and the downward hydraulic telescopic arm have a fixed square tube 5 and a sliding square tube that can slide in the fixed square tube 6. A hydraulic cylinder 7 is connected between the fixed square cylinder and the sliding square cylinder. The lower end of the downward hydraulic telescopic arm is connected with a longitudinal working wheel 8. The four corners of the flat frame are respectively connected with a downward screw driving the telescopic arm 9. The dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com