Assembly type beam column joint and construction method thereof

A beam-column joint and construction method technology, applied in building components, earthquake-proof, construction and other directions, can solve the problems of small lateral stiffness and poor seismic resistance, and achieve the improvement of seismic performance, reduction of residual deformation, and good structural function recovery ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

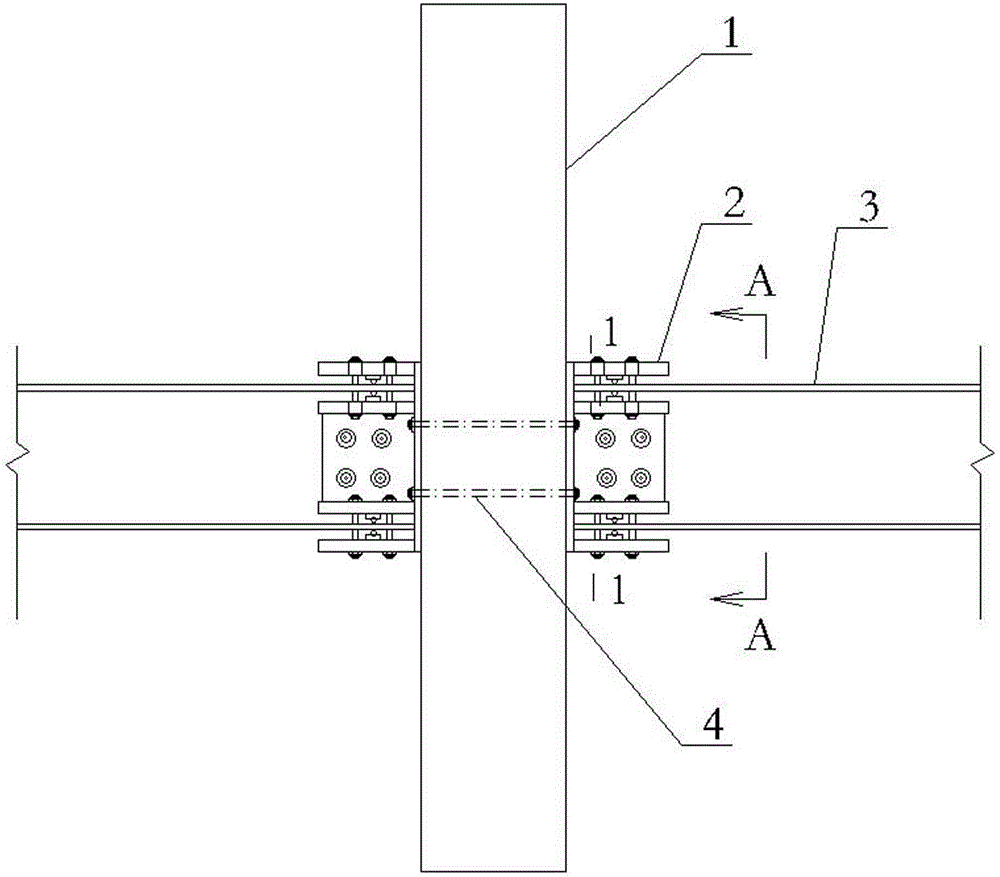

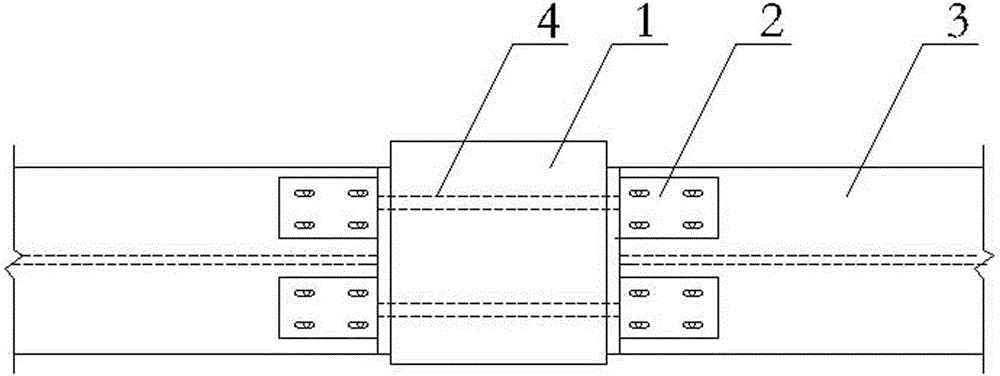

[0027] Such as figure 1 A specific embodiment shown in -4, which includes a concrete column 1, two H-shaped steel beams 3 and two connecting pairs 2. One ends of the two H-shaped steel beams 3 are respectively connected to both sides of the concrete column 1 through a connecting pair 2 .

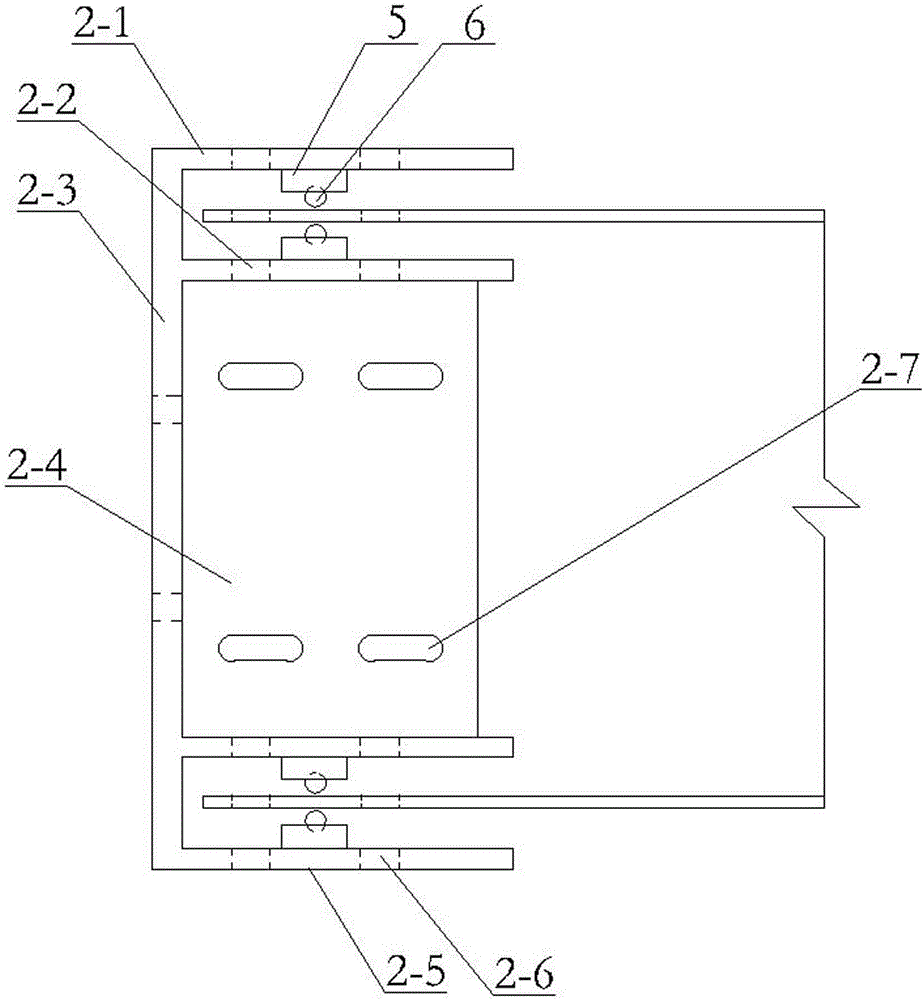

[0028] Such as image 3 As shown in Figure 4, the connection pair 2 includes an end plate 2-3, an upper wing plate 2-1 and a lower wing plate 2-5 respectively fixed on the upper and lower ends of the end plate 2-3, fixed on the end plate 2-3, the upper The web 2-4 between the wing plate 2-1 and the lower wing plate 2-5, the upper wing plate 2-1 includes upper and lower layers, and the upper and lower upper wing plates 2-1 are fixed with the end plate 2-3, Lower wing plate 2-5 comprises upper and lower two layers, and upper and lower lower wing plate 2-5 of two layers is all fixed with end plate 2-3, and the middle part of every layer of upper wing plate 2-1 and every layer of lower wing pl...

specific Embodiment 2

[0033] Such as Figure 7 - Figure 11 As shown, the difference between the second embodiment and the first embodiment is as follows: the connecting pair 2 has no web plate, the end of the H-shaped steel beam 3 far away from the concrete column is provided with a beam end plate 13, and the concrete column 1 is pre-embedded with an isolation pipe 11. The isolating pipe 11 is made of PVC pipe or other materials. The isolating pipe 11 is provided with slidable prestressed tendons 12. The two ends of the prestressed tendons 12 protrude from the concrete column 1 and are respectively fixed on two H-shaped steel bars. On the beam end plate 13 of the beam 3, the prestressed tendon 12 replaces the anchor bolt 4 in the first embodiment.

[0034] The construction method of the present specific embodiment is as follows: the specific embodiment of the present invention comprises the following steps: (1) bind the longitudinal bars and stirrups of the concrete column 1, make the reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com