Preparation method of hydrogenation catalyst

A hydrogenation catalyst, alumina technology, applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems such as the inability to reflect the excellent performance of the composite carrier, the damage to the pore structure of the carrier, and the difficulty of effective combination, etc. Achieve high acidity, avoid agglomeration, avoid uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

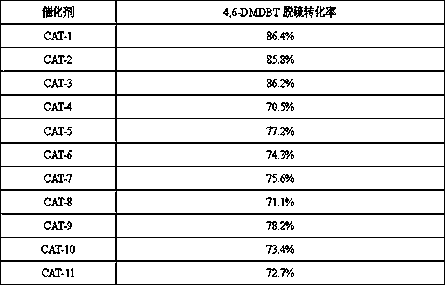

Examples

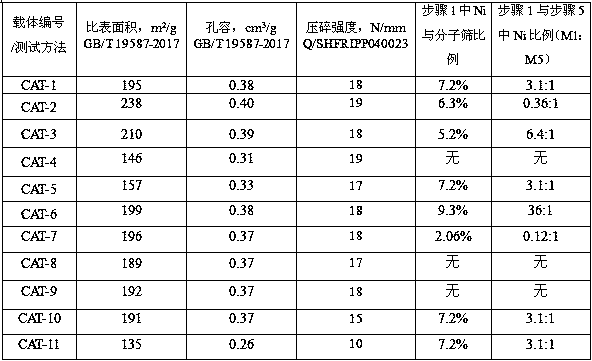

Embodiment 1

[0038] Put 1 L of aluminum sulfate solution (concentration of 0.2 mol / L) and 1 L of sodium metaaluminate solution (concentration of 0.3 mol / L) in the raw material tank respectively, and place 1 L of pure water in the reaction tank as the bottom liquid, pass The temperature of the reaction tank is controlled to 60° C. by water circulation, and a small amount of sodium hydroxide is added to make the pH value of the solution 8.5. Inject the aluminum sulfate solution into the reaction tank at a rate of 10 mL / min, and at the same time inject the sodium metaaluminate solution and adjust the rate so that the pH value of the reaction tank solution is constant at 8.8. After 60 min, the neutralization is completed, and the Na is fully washed to remove + ions and SO 4 2- After ionization, a certain amount of deionized water was added to obtain pseudo-boehmite slurry A with a solid-to-liquid ratio of 8% (calculated as alumina).

Embodiment 2

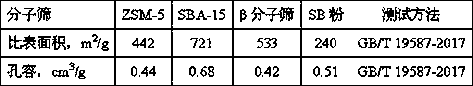

[0040] 50g ZSM-5 molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 30.0, the unit cell constant is 20Å, and the relative crystallinity is 85%) is placed in a rolling pot, and under the condition of rotation, 70ml of ZSM-5 molecular sieves in the rolling pot are sprayed into 70ml containing 14.0g of hexahydrate Aqueous solution of nickel nitrate, after the solution is sprayed, continue to rotate in the rolling pot for 30 minutes, then place it for 3 hours, dry it at 110°C for 3 hours, put it into a muffle furnace and roast it for 2 hours at a roasting temperature of 500°C to obtain the modified ZSM-5 molecular sieve.

[0041] Put the modified ZSM-5 molecular sieve obtained above into the 625g pseudoboehmite slurry A obtained in Example 1, add 200g ethanol after stirring evenly, and then add 50g tetraethoxysilane after continuous stirring. After stirring evenly, a small amount of tetramethylammonium hydroxide was added to adjust the pH value of the slurry to 8.5. Put it i...

Embodiment 3

[0044] 20g SBA-15 mesoporous molecular sieve (SiO 2 / Al 2 o 3 The molar ratio is 35.0) placed in a rolling pot, and under the condition of rotation, spray 70ml of an aqueous solution containing 4.9g of nickel nitrate hexahydrate into the SBA-15 mesoporous molecular sieve in the rolling pot in an atomized manner. After the solution is sprayed, the Continue to rotate in the rolling pot for 30 minutes, then place it for 3 hours, dry it at 110°C for 3 hours, put it into a muffle furnace and roast it for 2 hours at a roasting temperature of 500°C to obtain a modified SBA-15 mesoporous molecular sieve.

[0045] Put the above-mentioned modified SBA-15 mesoporous molecular sieve into the 1000g pseudoboehmite slurry A obtained in Example 1, and then add 800g of isopropanol after stirring evenly, and then add 120g of dimethylvinyl Ethoxysilane, after stirring continuously, add a small amount of triethanolamine to adjust the pH value of the slurry to 9.0. Put it in a closed autoclave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com