A kind of propane dehydrogenation propylene composite alumina support catalyst and preparation method thereof

A composite alumina and propane dehydrogenation technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of catalyst strength not mentioned, not involved To adjust the characteristics of alumina carrier and its forming process, etc., to achieve the effect of suitable carrier pore structure, high propylene selectivity and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of a propane dehydrogenation propylene composite alumina carrier catalyst, comprising the following steps:

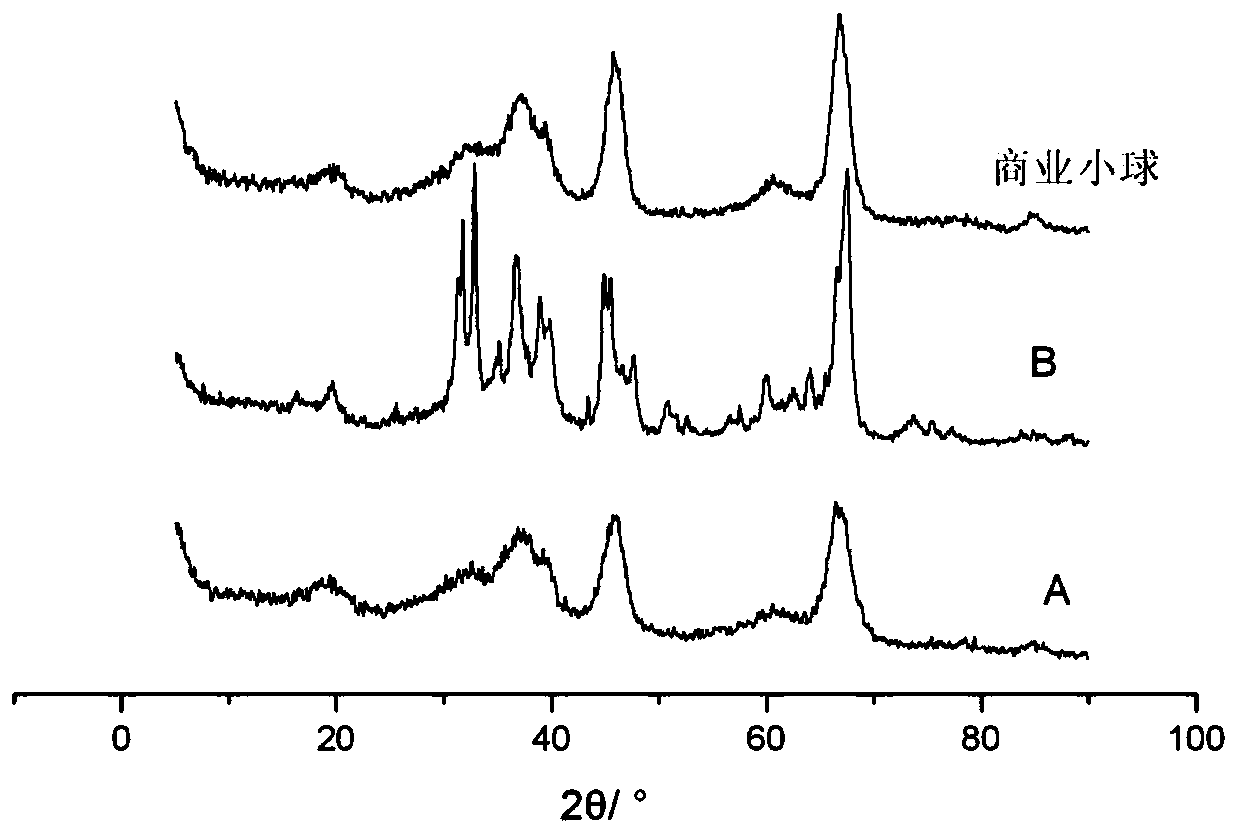

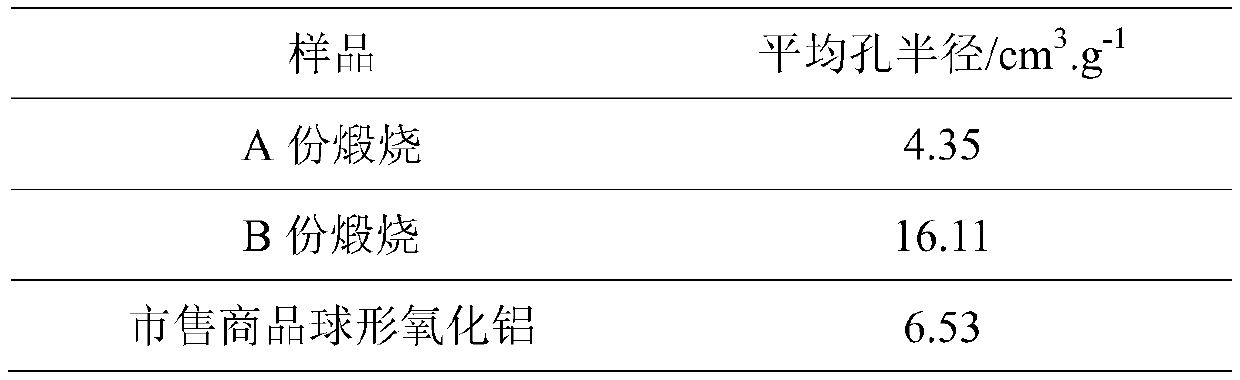

[0031] 1) Divide pseudo-boehmite into part A and part B, calcining part A of pseudo-boehmite in a tube furnace under air ventilation conditions, and simultaneously calcining part B of pseudo-boehmite in a tube furnace , Mix the powders of Part A and Part B calcined above and grind them for use.

[0032] Specifically, according to the mass ratio of γ-alumina and θ-alumina in the catalyst composite alumina carrier, pseudo-boehmite is divided into A part and B part, wherein the mass of A part corresponds to the mass ratio of γ-Al 2 o 3 , the mass of B parts corresponds to θ-Al 2 o3 , and then calcining part A of pseudo-boehmite in a tube furnace at 450-750°C for 3-5 hours under the condition of air ventilation; at the same time, calcining part B of pseudo-boehmite in a tube furnace at 900-1150°C Calcining for 3-5 hours under the same conditio...

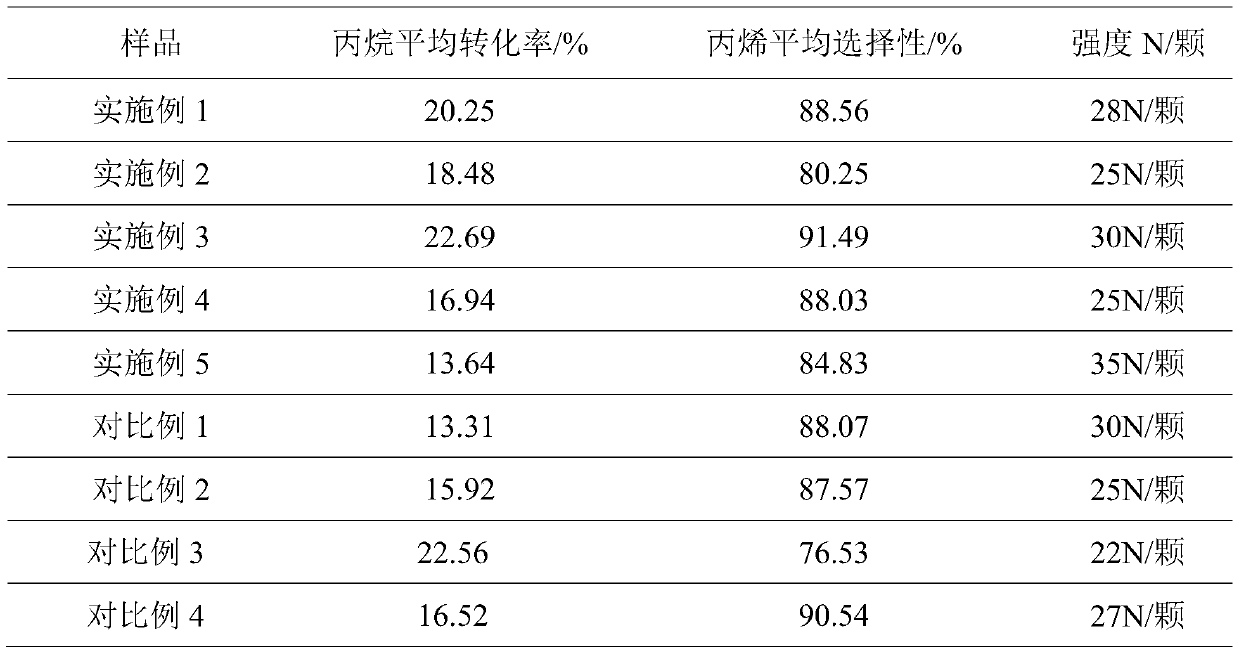

example 1

[0045] 1. Divide pseudo-boehmite into part A and part B according to the mass, and the mass ratio of the two is 3:7; calcinate part A of pseudo-boehmite in a tube furnace at 450°C for 8 hours under the condition of air ventilation ; Simultaneously calcining part B of pseudo-boehmite in a tube furnace at 1050°C for 4 hours; mixing the calcined powders of part A and part B above and grinding them for use.

[0046] 2. After mixing the weighed chlorides of modifiers Sn, Zn, K and Ce, add distilled water to dissolve to form a mixed solution of four chlorides.

[0047] 3. Pour the mixed material in step 1) into the kneader, turn on the kneading function, and then add the solution prepared in step 2) dropwise; after kneading for 4 hours, take it out and put it in an oven to dry at 100°C, and Calcined at 450°C for 8h.

[0048] 4. After fully grinding the catalyst precursor prepared in step 3), add the peptizer. The peptizer is aluminum sol, the amount of which is 8% of the mass of t...

example 2

[0052] 1. Divide pseudo-boehmite into part A and part B according to the mass, and the mass ratio of the two is 4:6; calcinate part A of pseudo-boehmite in a tube furnace at 750°C for 4 hours under the condition of air ventilation ; Simultaneously calcining part B of pseudo-boehmite in a tube furnace at 950°C for 5 hours; mixing the calcined powders of part A and part B above and grinding them for use.

[0053] 2. After mixing the weighed chlorides of modifiers Sn, Ge, Ca and La, add distilled water to dissolve to form a mixed solution of four chlorides.

[0054] 3. Pour the mixed material in step 1) into the kneader, turn on the kneading function, and then add the solution prepared in step 2) dropwise; after kneading for 4 hours, take it out and put it in an oven to dry at 100°C, and Calcined at 550°C for 4h.

[0055] 4. After fully grinding the catalyst precursor prepared in step 3), add the peptizer. Wherein the peptizing agent is an aluminum sol, and its addition amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com