Construction method of a carrier pile

A construction method and technology of carrier piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of reducing work efficiency, increasing the disturbance of the bearing layer at the pile end, and disturbing the bearing layer, so as to improve the forming speed and work efficiency , Improve the scope of application, the effect of small tamping energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below by specific examples.

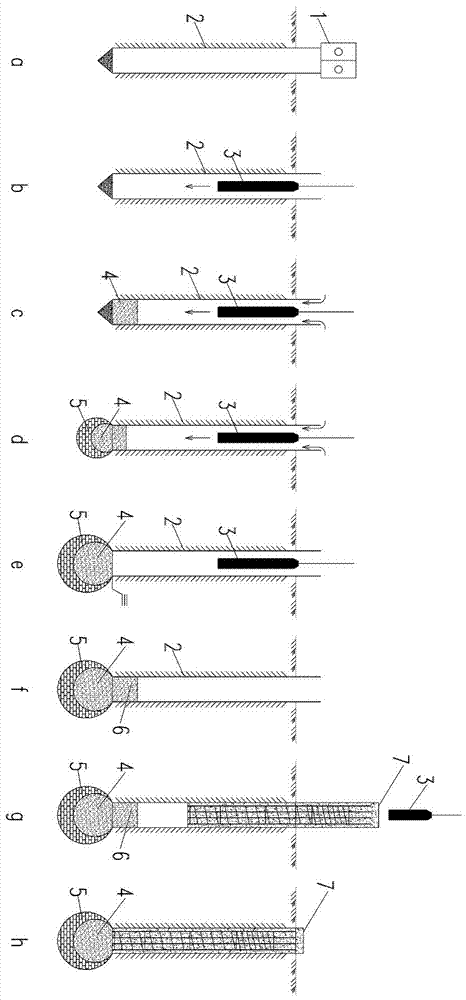

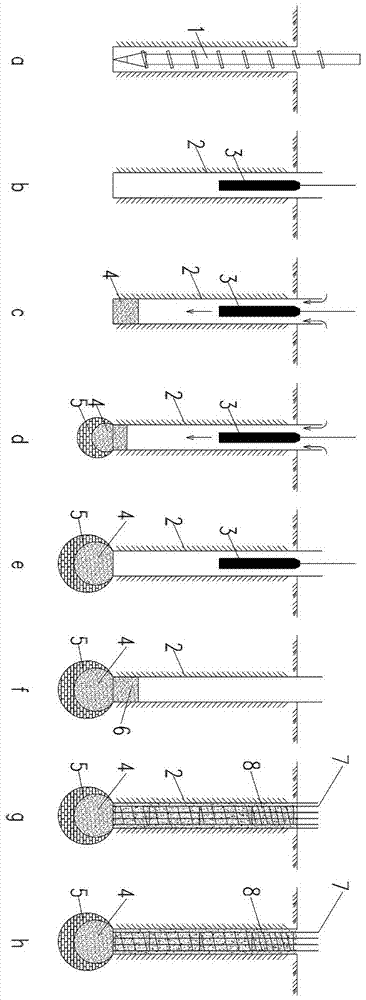

[0031] figure 1 It is a process diagram of an embodiment of the carrier pile construction method of the present invention, at first, as figure 1 As shown in a, at the pile position in the foundation, the casing 2 with the prefabricated pile tip is sunk to the design depth by the vibration of the vibrator 1; then, as figure 1 As shown in middle b, a heavy hammer 3 is placed in the casing 2, and the gap between the outer wall of the heavy hammer 3 and the inner wall of the casing 2 is 5 cm; then, as figure 1As shown in c, the filling and heavy hammer tamping operations are performed simultaneously, that is, the mixture 4 composed of cement, sand and small-sized crushed stones is filled into the casing 2 through the upper opening of the casing 2, and the mixture 4 is lifted upwards. After the heavy hammer 3, let the heavy hammer 3 fall freely to tamp the cement mixture 4. The maximum particle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com