Plugging thixotropic cement paste for oil-gas well and preparation method for same

A technology for oil well cement and oil and gas wells, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult to guarantee durability, complex process, difficult implementation, etc., and achieve stable engineering performance, simple process, and practical scope. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

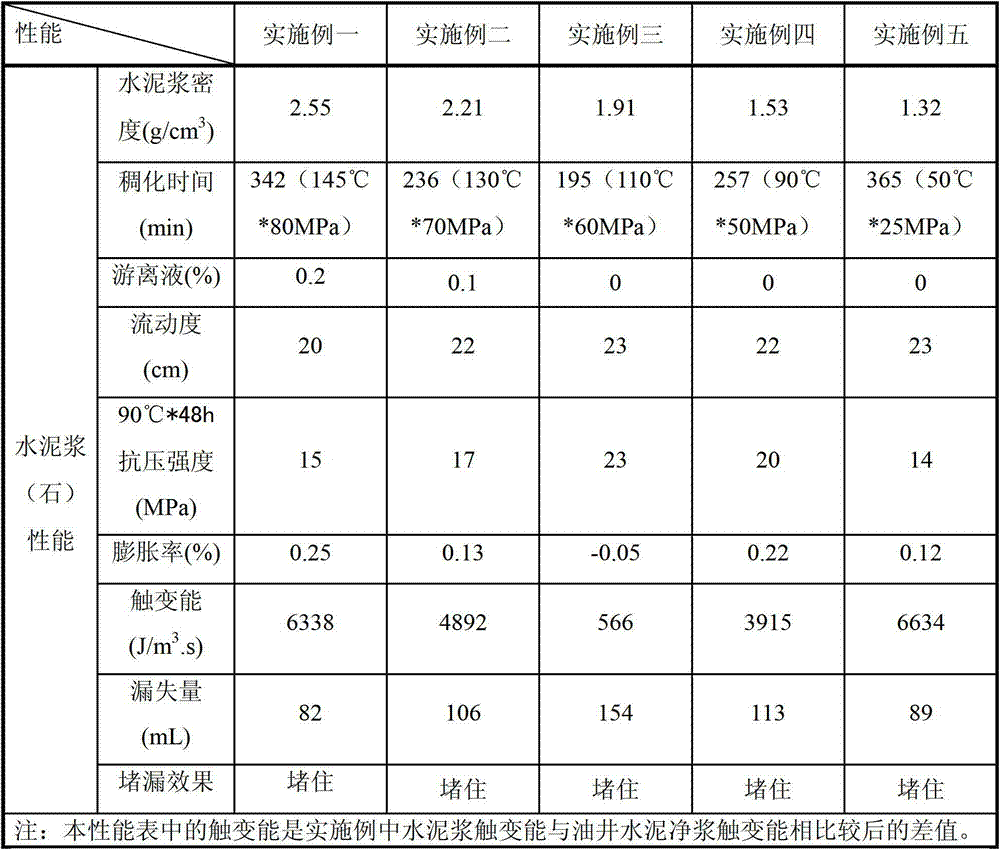

Examples

Embodiment 1

[0014] Weigh 100 parts by weight of oil well cement, 200 parts by weight of density modifier, 35 parts by weight of stabilizer, 5 parts by weight of expansion agent and 3 parts by weight of dispersant and dry mix them into dry powder; measure 100 parts by weight of water, and weigh 6 parts by weight of setting time regulator Parts by weight, 10 parts by weight of the thixotropic agent, dissolved in water to obtain an aqueous solution. Then, put the aqueous solution in a special mixing container, turn the agitator at a low speed (4000±200 rpm), and add the weighed dry powder within 15 seconds, cover the lid of the agitator, and turn it at a high speed (12000±500 rpm). rpm) for 35 seconds, add 2 parts by weight of defoamer, stir gently with a wooden stick to remove air bubbles, and obtain the cement slurry for preventing external corrosion of casing of the present invention.

Embodiment 2

[0016] Weigh 100 parts by weight of oil well cement, 100 parts by weight of density modifier, 20 parts by weight of stabilizer, 3 parts by weight of expansion agent and 2 parts by weight of dispersant and dry mix them into dry powder; measure 120 parts by weight of water, weigh 3 parts by weight of setting time regulator Parts by weight, 6 parts by weight of the thixotropic agent, dissolved in water to obtain an aqueous solution. Then, put the aqueous solution in a special mixing container, turn the agitator at a low speed (4000±200 rpm), and add the weighed dry powder within 15 seconds, cover the lid of the agitator, and turn it at a high speed (12000±500 rpm). rev / min) to continue stirring for 35 seconds, add 1 part of defoamer, stir gently with a wooden stick, remove air bubbles, and obtain the cement slurry for preventing external corrosion of casing of the present invention.

Embodiment 3

[0018] Weigh 100 parts by weight of oil well cement and 0.5 parts by weight of dispersant and dry mix them into dry powder; measure 60 parts by weight of water, weigh 0.5 parts by weight of setting time modifier and 0.5 parts by weight of thixotropic agent, and dissolve them in water to obtain an aqueous solution. Then, put the aqueous solution in a special mixing container, turn the agitator at a low speed (4000±200 rpm), and add the weighed dry powder within 15 seconds, cover the lid of the agitator, and turn it at a high speed (12000±500 rpm). rpm) for 35 seconds, add 0.2 parts of defoamer, stir gently with a wooden stick to remove air bubbles, and obtain the cement slurry for preventing external corrosion of casing of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com