Evaluation device and method capable of eccentricity testing of cementation quality of well cementation first interface

A technology of quality evaluation and interface glue, applied in construction and other directions, can solve problems such as failure to reflect formation pore pressure, inability to distinguish and study, and ignoring casing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

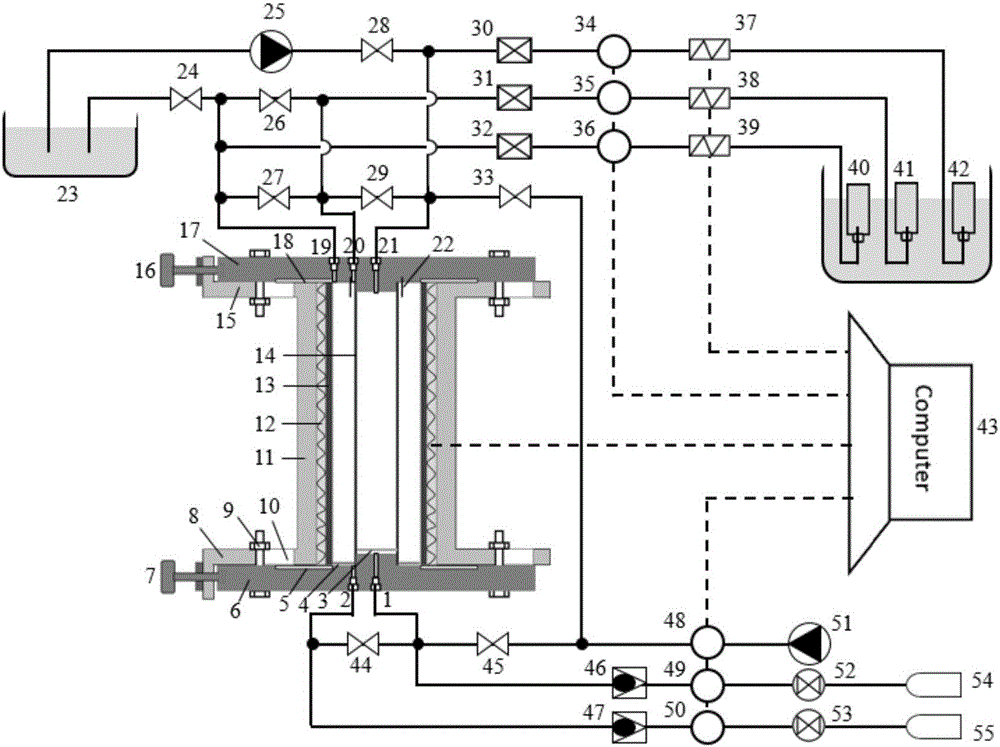

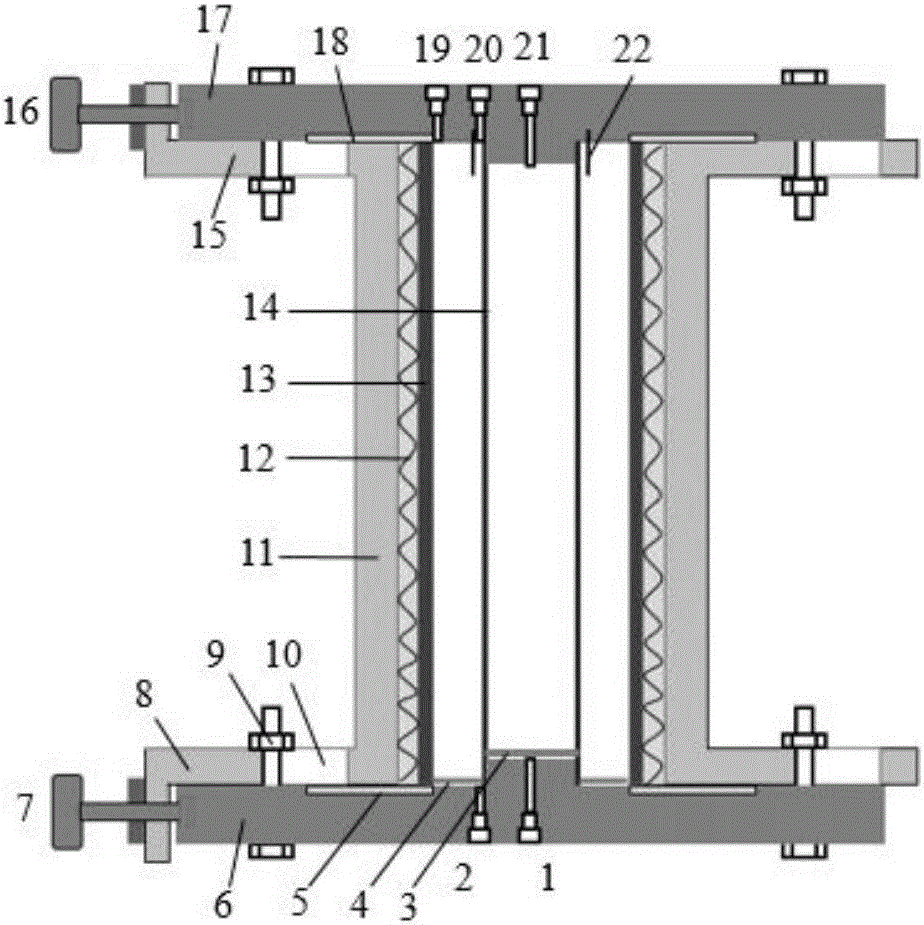

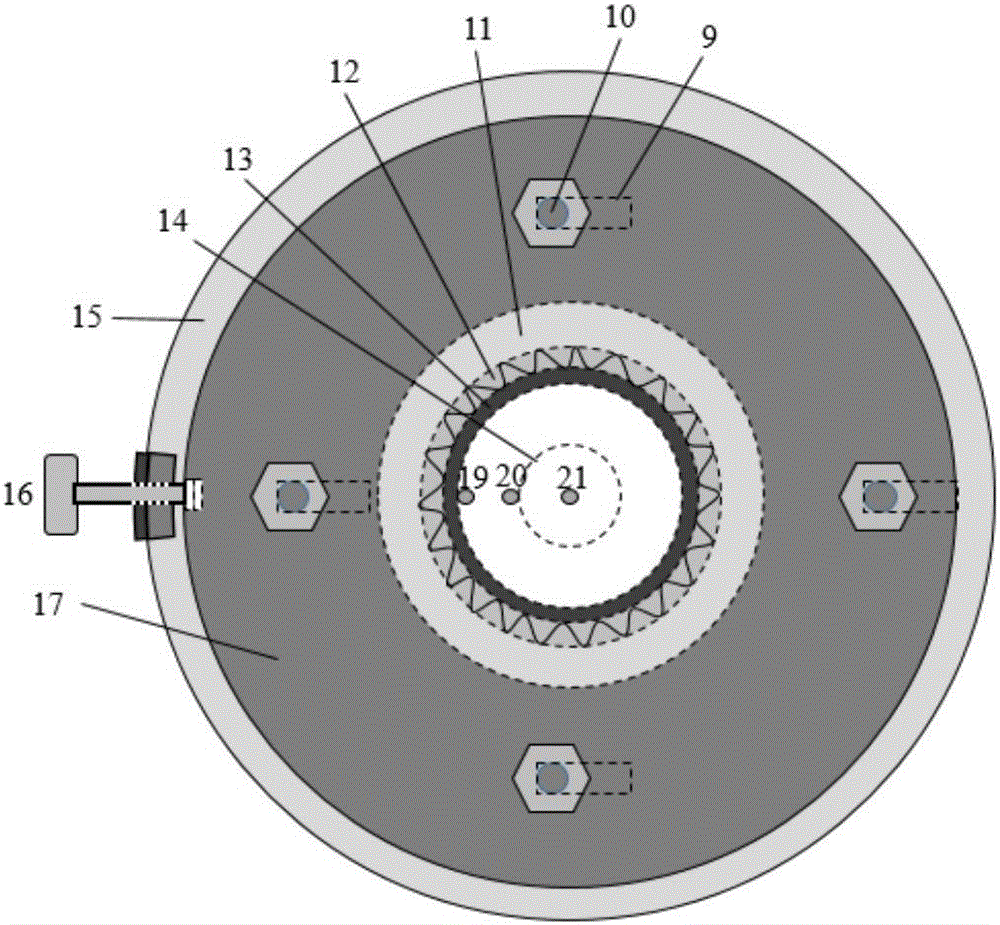

Embodiment 1

[0038] A cementing-interface bonding quality evaluation device capable of eccentric testing, mainly composed of a casing inlet 1, an annular air inlet 2, wool pads 3, 4, annular sealing rings 5, 18, a lower cover 6, a lower Adjusting screw 7, lower kettle body 8, pressure screw 9, screw translation groove 10, side kettle body 11, heating insulation cover 12, stratum simulation layer 13, casing 14, upper kettle body 15, upper adjusting screw 16, upper cover 17. Second interface gas outlet 19, first interface gas outlet 20, casing gas outlet 21, spacer ring 22, drilling fluid pool 23, control valves 24 (first), 26 (second), 27 (third) , 28 (fourth), 29 (fifth), 33 (sixth), 44 (seventh), 45 (eighth), mud pump 25, back pressure valve 30 (first), 31 (second), 32 (third), pressure gauge 34 (first), 35 (second), 36 (third), 48 (fourth), 49 (fifth), 50 (sixth), flow meter 37 (first ), 38 (the second), 39 (the third), gas cylinder 40 (the first), 41 (the second), 42 (the third), compu...

Embodiment 2

[0056] Adopt the experimental method of the evaluation device of a kind of cementing second interface cementing quality described in embodiment 1, comprise the steps:

[0057] 1. Adjust the eccentricity:

[0058] (1) Take off the upper cover 17 and the lower cover 6, connect the casing 14 and the lower cover 6, and seal the joints of the two with rubber rings, and then connect the lower cover 6 to the Lower kettle body 8, now pressure-bearing screw 9 needn't be tightened.

[0059] (2) Turn the lower adjustment screw 7. Since the pressure-bearing screw 9 is not tightened, the casing 14 will translate the same distance with the lower cover 6 at this time, and can be adjusted to the eccentricity required for the experiment.

[0060] (3) Immediately tighten the pressure-bearing screw 9 after reaching the eccentricity required for the experiment, and seal the connection between the upper cover 17 and the casing 14, and tighten the corresponding pressure-bearing screw.

[0061] 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com