Construction method for static pressure carrier pile

A construction method and carrier pile technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as increasing construction difficulty, reducing construction work efficiency, reducing work efficiency, etc., reducing the process of ramming and filling dry and hard concrete, and improving The bearing capacity of pile foundation and the effect of improving the strength of the carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below by specific examples.

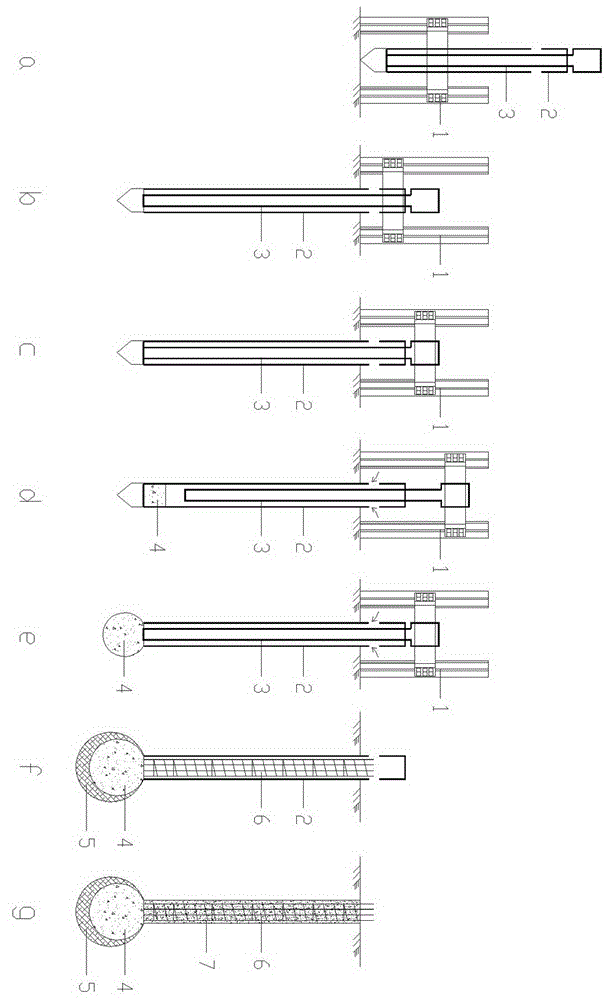

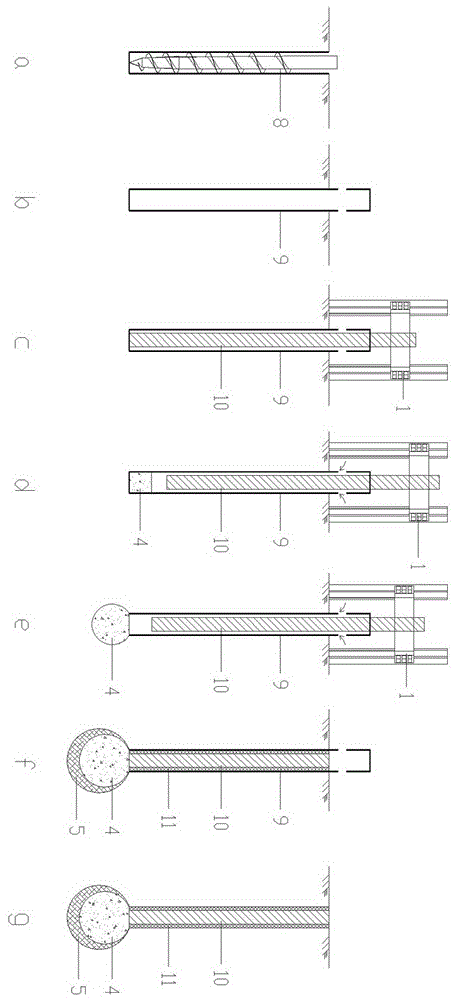

[0033] figure 1 It is a process diagram of an embodiment of the static pressure carrier pile construction method of the present invention, at first, as figure 1 As shown in middle a, the clamping system 1 of the static pressure pile machine holds the outer pipe 2, and the inner pipe 3 is nested in the outer pipe 2, and the diameter of the upper part of the inner pipe 3 is thickened and equal to the outer diameter of the outer pipe 2; then ,Such as figure 1 As shown in middle b, a prefabricated pile tip is placed at the bottom of the outer pipe 2, and the outer pipe 2 is statically pressed into the soil to the design depth; then, as figure 1 As shown in middle c, loosen and move up the clamping system 1 to hold the inner tube 3; then, as figure 1 As shown in middle d, the clamp inner tube 3 is raised to a certain height, and the filler opening at the upper end of the outer tube 2 is filled w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com