Natural gas demercuration adsorbent and preparation method

An adsorbent and natural gas technology, applied in chemical instruments and methods, gas fuel, petroleum industry, etc., can solve the problems of unstable pore volume and channel size, large amount of mercury removal agent, slow mercury removal speed, etc. The effect of fast mercury velocity, stable pore volume and channel size, and large mercury capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] At room temperature, dissolve 5g of sulfur in 70mL of carbon disulfide to make a carbon disulfide-sulfur solution, take 100g of it, the diameter is 2mm, and the pore volume is 0.3cm 3 / g, the specific surface area is 130m 2 / g γ-Al 2 o 3 The particles were soaked in the above sulfur solution, filtered after 2 hours, and dried at 50°C until constant weight, with a mass of 104.0g. Then use 80mL concentration of 10% copper sulfate pentahydrate solution to impregnate the above γ-Al 2 o 3 The particles were filtered after 30 minutes and dried at 105°C until constant weight, with a mass of 109.7g. Put the above product into a glass reaction tube, pass H at 60°C 2 S gas, make copper sulfate and H 2 S reacts to form copper sulfide, which is taken out, washed with deionized water to remove sodium sulfate, and then dried at 100°C to obtain the product.

Embodiment 2

[0022] The mercury removal adsorbent prepared in Example 1 above was loaded into a natural gas mercury removal adsorption evaluation device for evaluation. The mercury content of natural gas reaches 199μg / m by supplementing mercury 3 .

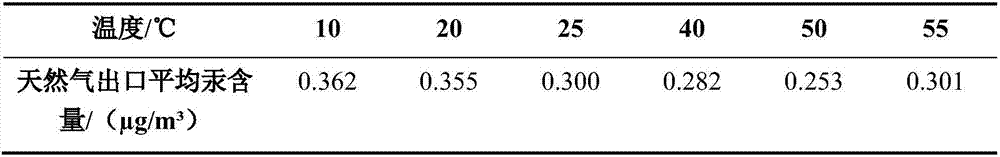

[0023] The residence time is 3s, the operating pressure is 6Mpa, and the mercury concentration is 199μg / m 3 , the liquid hydrocarbon content is 5ppm, and the free water content is 20ppm, the effect of temperature on mercury removal is investigated. The experimental results are shown in Table 1.

[0024] Table 1 Effect of temperature on mercury removal effect

[0025]

[0026] The results show that when the residence time is 3s, the operating pressure is 6Mpa, and the mercury concentration is 199μg / m3 at 10-55℃ 3 Can be reduced to not higher than 0.362μg / m 3 .

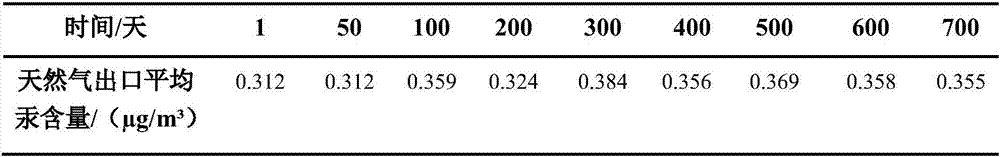

[0027] At a temperature of 25°C, a residence time of 3s, an operating pressure of 6Mpa, a free water content of 20ppm, a liquid hydrocarbon content of 5ppm, and a mercury conce...

Embodiment 3

[0032] 100g has a diameter of 2mm and a pore volume of 0.3cm 3 / g, the specific surface area is 130m 2 / g γ-Al 2 o 3 The measured water absorption rate is 60%. After drying at 105°C, soak it in 75mL of 10% sulfur solution for 2 hours and filter it; The solution was impregnated for 30min, then filtered, dried at 105°C to constant weight, the mass was 110.6g, and then 0.03mol / L Na 2 S solution is vulcanized; soaked for 24 hours, filtered, washed with deionized water to remove sodium nitrate, and dried at 110°C to obtain a natural gas mercury removal adsorbent. Put the mercury removal adsorbent on the fixed bed reactor, at room temperature, feed 199ug / m 3 The mercury-containing natural gas was finally measured to have a mercury capacity of 8.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com