CMP polishing heads retaining ring groove design for microscratch reduction

a technology polishing head, which is applied in the field of retaining ring groove design of cmp head, can solve the problems of micro-scratches formed on the substrate, and achieve the effect of reducing repetition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Introduction

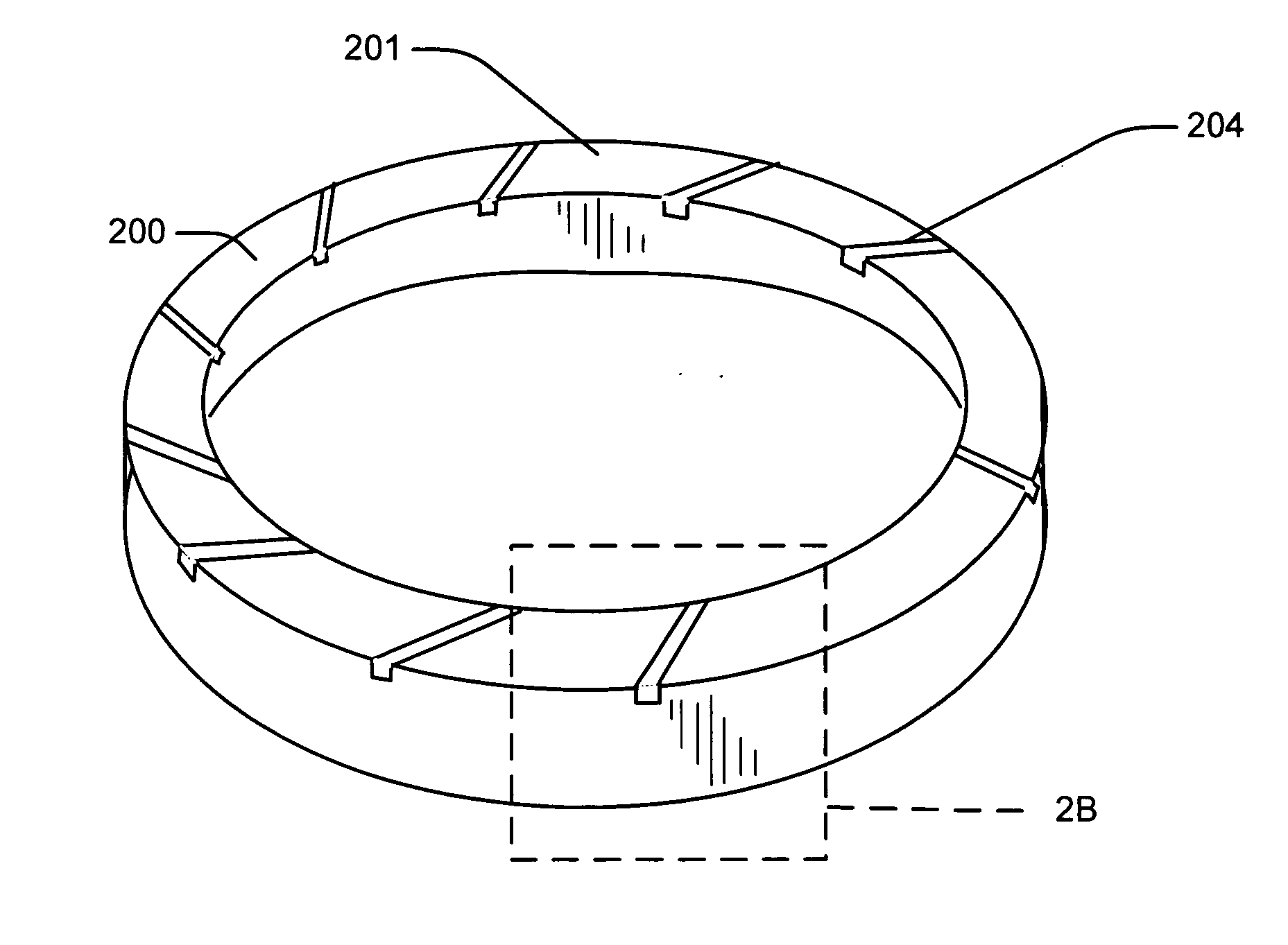

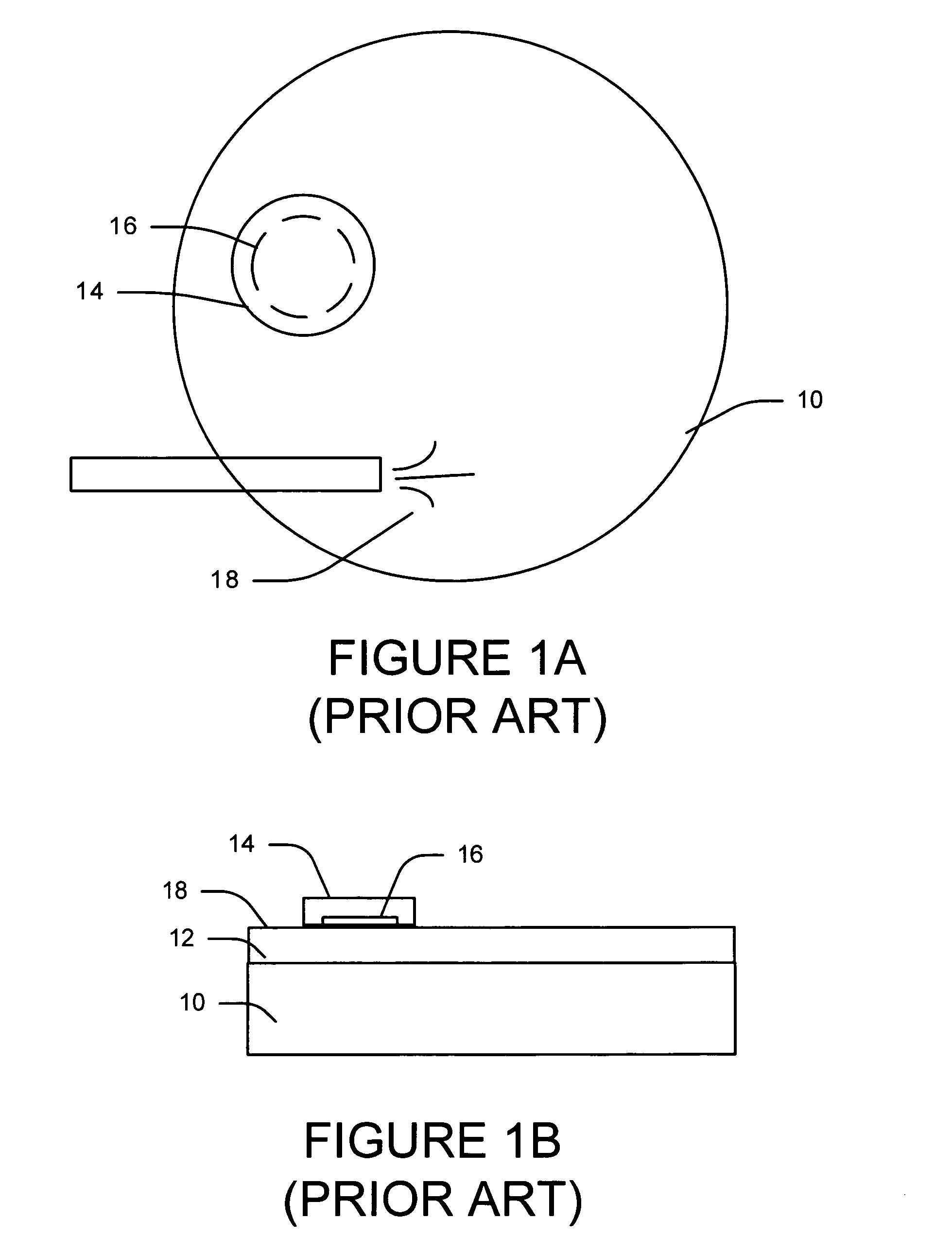

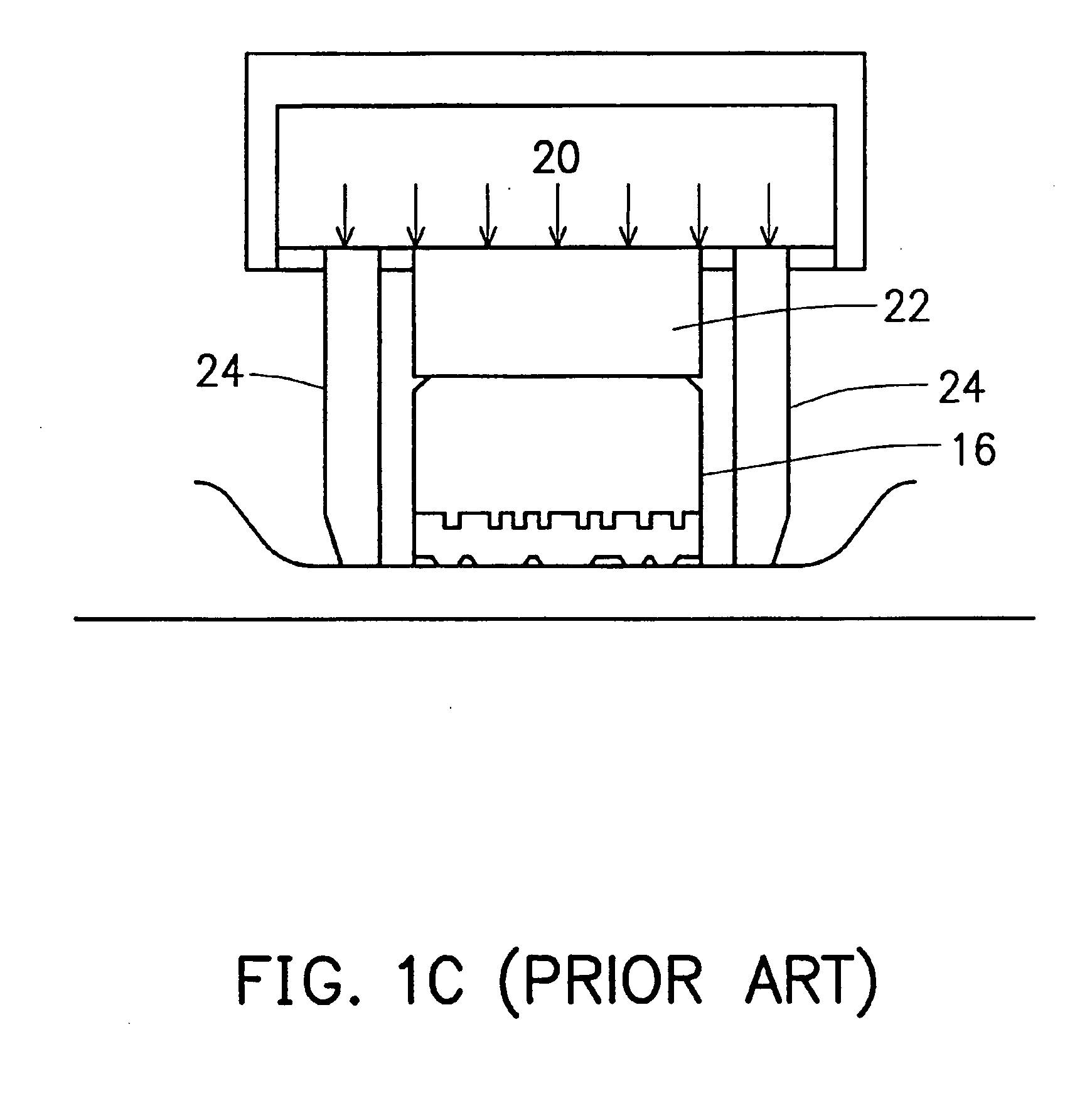

[0049] Referring now to the drawings and more particularly to FIGS. 2A, 2B, and 2C, there is shown a retaining ring 200 over which the aspects of the present invention are an improvement. It is to be understood in this regard that no portion of FIGS. 2A, 2B and 2C is admitted to be prior art as to the present invention. Rather, this these diagrams are an effort to provide an improved understanding of some of the problems that are overcome by the aspects of the invention.

[0050]FIG. 2A is perspective view of a retaining ring 200 having rectangular shaped grooves 204. The ring has a lower surface 201 (polishing surface or pad side surface) that in operation faces the polish pad.

[0051]FIG. 2B is a close up perspective view a groove 204 that has non-curved corners or edges in the a retaining ring 200.

[0052]FIG. 2C is a cross sectional view of a groove 204 that has slurry particles or other debris 208 that cause the problems as discovered by the inventors.

[0053] Microscr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com