Electric power steering device

An electric steering and motor technology, applied in electric steering mechanisms, transmissions, belts/chains/gears, etc., can solve the problems of large nut diameter, increased nut axial length, inability to realize compact design of electric steering devices, etc. Rolling, low vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

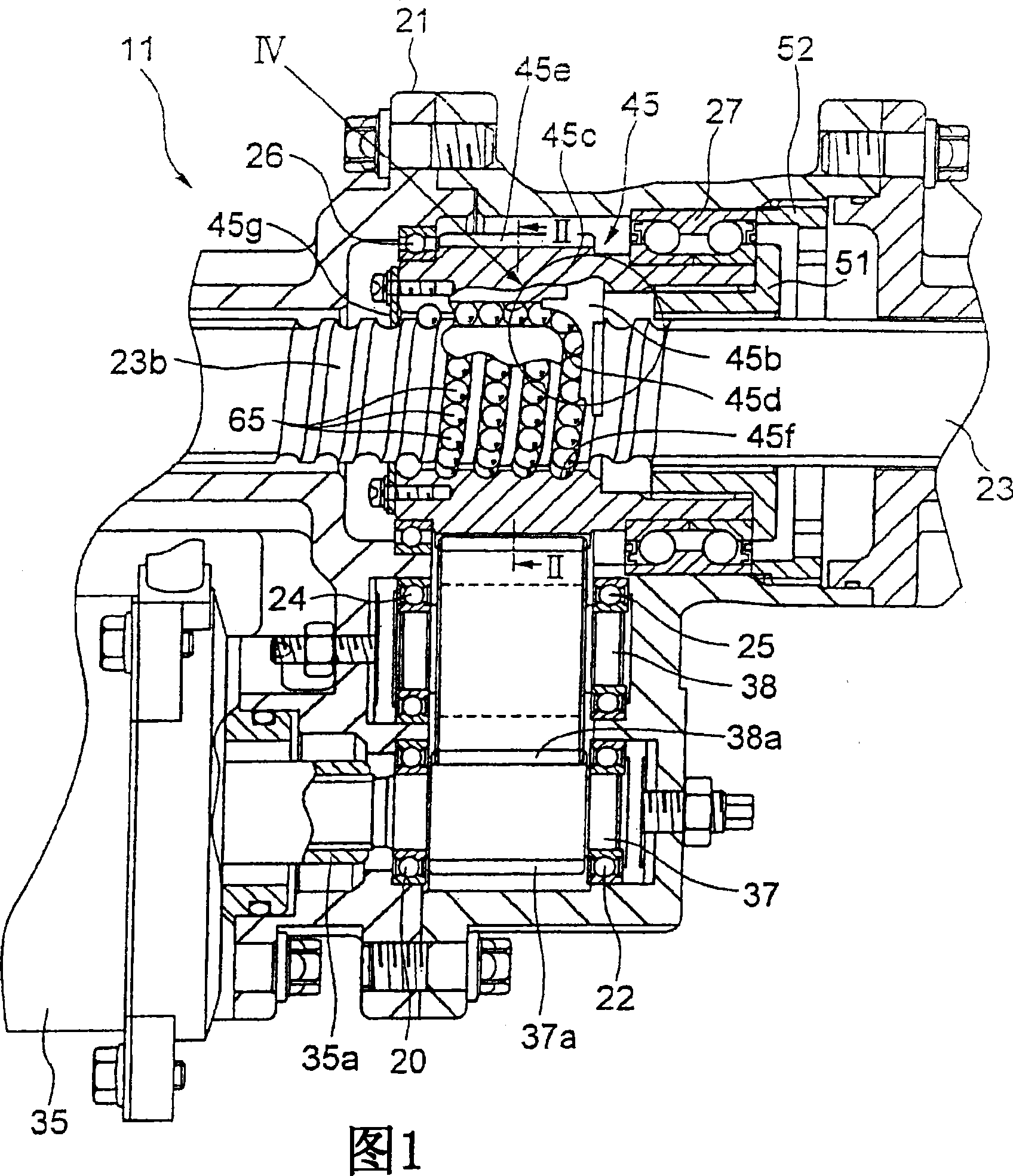

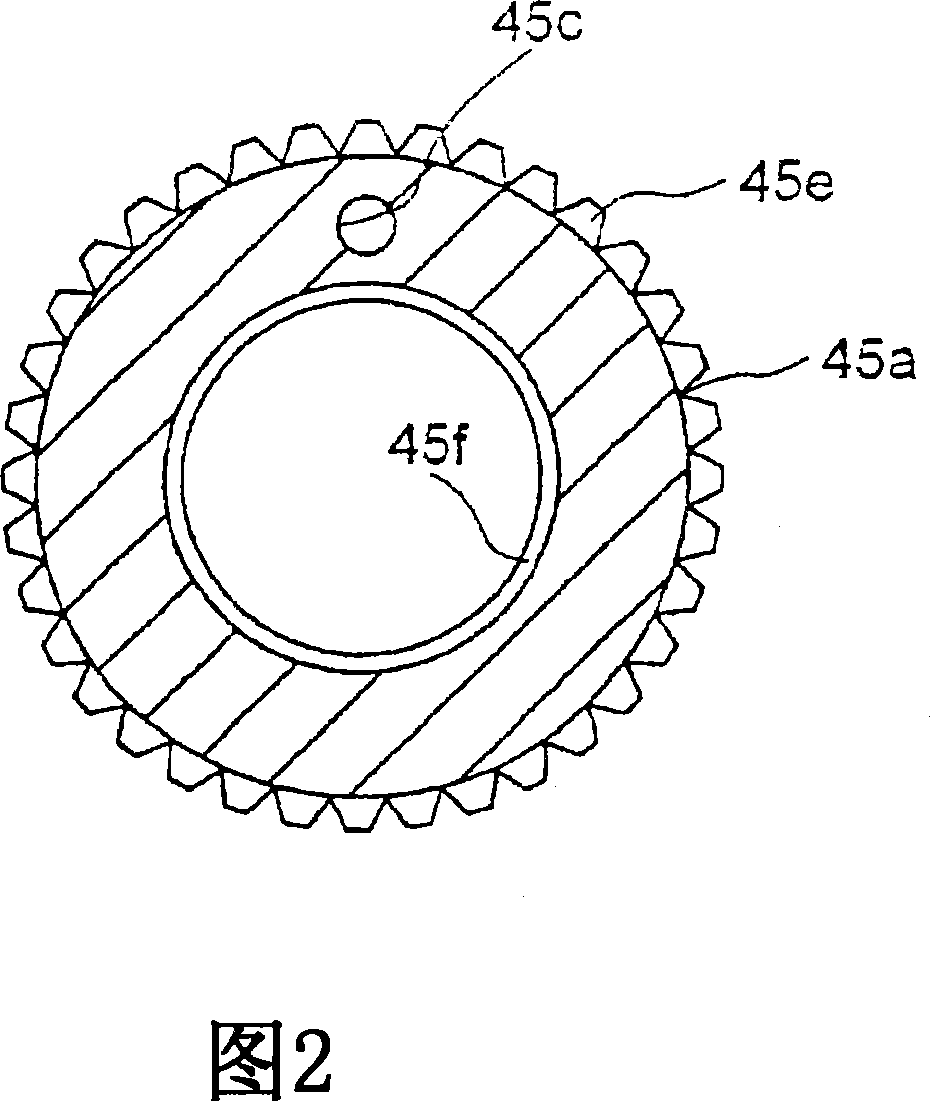

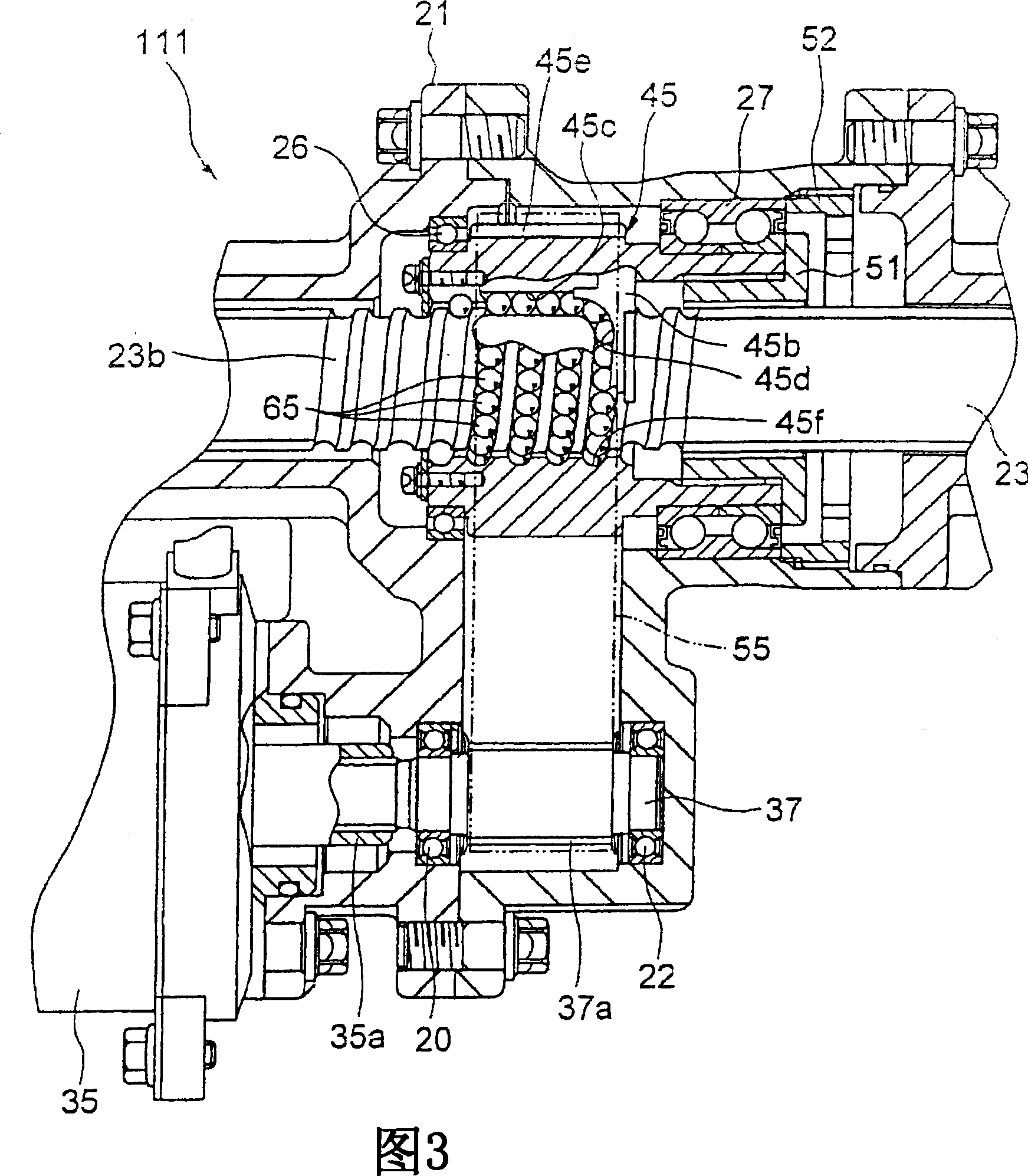

[0153] Embodiments of the present invention will now be described with reference to the accompanying drawings. FIG. 1 is a sectional view of an essential part of an electric power steering apparatus of a first embodiment. Figure 2 is a view taken along the line II-II of the nut of Figure 1, viewed in the direction of the arrow, but with the threaded shaft and balls omitted. In FIG. 1 , an electric power steering device 11 includes a housing 21 fixed to an unshown vehicle body. The rack shaft 23 extends through the housing 21 in the horizontal direction, and is supported so as to move in the axial direction. Although not shown, a pinion gear is formed at the lower end of the input shaft connected to the steering wheel, and meshes with the rack teeth of the rack shaft 23, and the rack shaft 23 moves left and right in the drawing by the rotation of the input shaft. . The opposite end of the rack shaft 23 is connected to a connecting rod (not shown) of the steering mechanism. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com