Bismuth titanate nanosheet/bismuth oxide chloride nanosheet composite photocatalyst in three-dimensional structure and preparation method of composite photocatalyst

A technology of bismuth oxychloride nanometers and nanosheets, which is applied in the field of photocatalysis, can solve the problems of failing to prepare heterojunction photocatalysts, and achieve the effects of high visible light utilization, high transmission efficiency, and complete crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 0.34g of bismuth oxide, 0.087g of titanium dioxide, 1.359g of potassium chloride and 1.067g of sodium chloride in a mortar, and their molar ratios are 2:3:50:50. After grinding evenly, the obtained light yellow The powder was placed in a quartz boat, calcined at 800° C. for 2 h, and after cooling to room temperature, the product was washed and dried to obtain bismuth titanate nanosheets. Take 1mmol of the obtained bismuth titanate nanosheets and disperse them in 30mL of ethanol, and then weigh 0.4mmol of bismuth nitrate and 0.4mmol of sodium chloride and disperse them in 10mL of ethylene glycol solution, mix and stir the two solutions until uniform, transfer to Put it in a hydrothermal kettle and put it in an oven to react at 160°C for 24 hours. After cooling to room temperature, it was washed and dried by centrifugation to obtain a bismuth titanate nanosheet / bismuth oxychloride nanosheet composite photocatalyst.

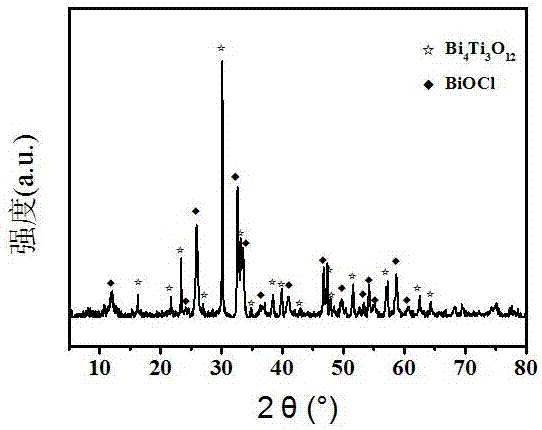

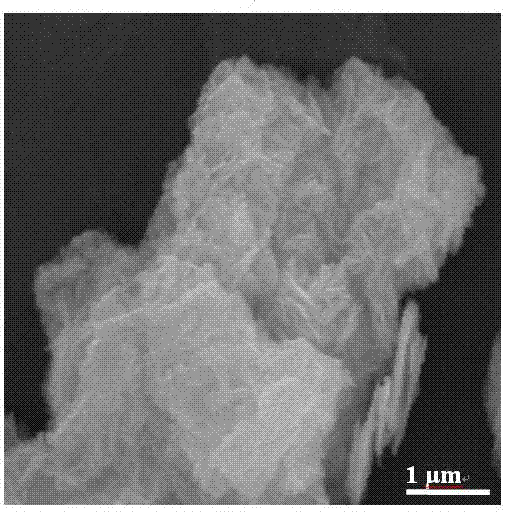

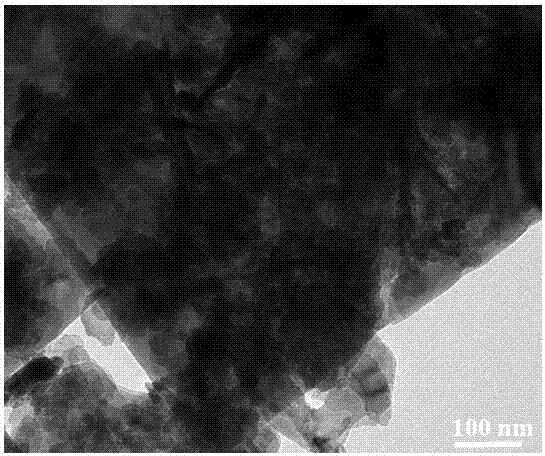

[0026] figure 1 For the XRD diffraction pattern o...

Embodiment 2

[0028] Take 0.34g of bismuth oxide, 0.087g of titanium dioxide, 0.815g of potassium chloride and 0.640g of sodium chloride in a mortar, and their molar ratios are 2:3:30:30 respectively. After grinding evenly, the obtained light yellow The powder was placed in a quartz boat, calcined at 800° C. for 2 h, and after cooling to room temperature, the product was washed and dried to obtain bismuth titanate nanosheets. Take 1mmol of the obtained bismuth titanate nanosheets and disperse them in 30mL of ethanol. In addition, weigh 1mmol of bismuth nitrate and 1mmol of sodium chloride and disperse them in 10mL of ethylene glycol solution. In the still, put it in an oven at 140°C for 10 hours, and after cooling to room temperature, wash and dry it by centrifugation.

Embodiment 3

[0030] Take 0.34g of bismuth oxide, 0.087g of titanium dioxide, 1.087g of potassium chloride and 0.854g of sodium chloride in a mortar, and their molar ratios are 2:3:40:40 respectively. After grinding evenly, the obtained light yellow The powder was placed in a quartz boat, calcined at 800° C. for 2 h, and after cooling to room temperature, the product was washed and dried to obtain bismuth titanate nanosheets. Take 1mmol of the obtained bismuth titanate nanosheets and disperse them in 30mL of ethanol. In addition, weigh 0.4mmol of bismuth nitrate and 1.2mmol of sodium chloride and disperse them in 10mL of ethylene glycol solution. Mix and stir the two solutions until uniform, transfer to In a hydrothermal kettle, put it in an oven at 150°C to react for 18 hours, and after cooling to room temperature, wash and dry by centrifugation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com