Integrated inspection bench for control system

A control system and inspection platform technology, applied in the field of inspection platform, can solve problems such as poor reliability and low efficiency, and achieve the effect of avoiding blind spots and increasing inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

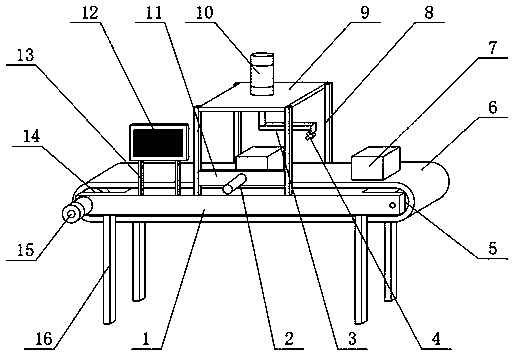

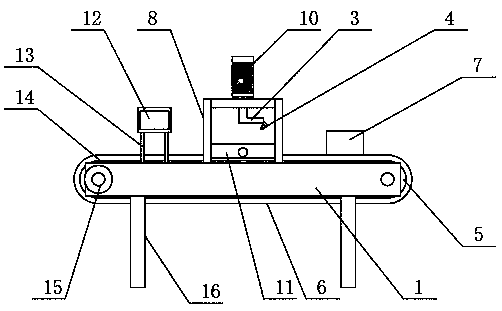

[0020] see Figure 1-3 , the present invention provides a technical solution for a control system integrated inspection platform: it includes an inspection platform body 1, and the two sides of the inspection platform body 1 are respectively rotatably connected with a driving roller 14 and a driven roller 5, and the driving roller 14 and the driven roller 5 They are connected by a transmission belt 6, and the front of the test bench body 1 is equipped with a second motor 15, the output shaft of the second motor 15 is connected to the drive roller 14 by transmission, and the top of the test bench body 1 is fixedly connected with four poles 8, The tops of the four poles 8 are fixedly connected with a support 9, the top of the support 9 is equipped with a first motor 10, the output end of the first motor 10 is connected with a support 3, and the end of the support 3 is equipped with a camera 4, a conveyor belt The top of 6 is provided with a system integration 7, and the system i...

Embodiment 2

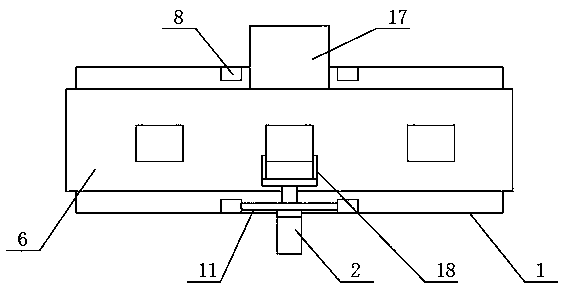

[0022] On the basis of embodiment one, refer to figure 2 to combine image 3 , wherein two poles 8 are fixedly connected with a side plate 11, the front of the side plate 11 is equipped with a cylinder 2, the telescopic end of the cylinder 2 is fixedly connected with a push plate 18, and the other two poles 8 are fixedly connected with a support plate 17, two Each support plate 17 is equal to the conveyor belt 6. When the present invention detects unqualified products, the cylinder 2 pushes the system integration 7 to the support plate 17 through the push plate 18, thereby separating unqualified products and qualified products in time. , qualified products are conveyed to the left through conveyor belt 6.

[0023] During specific use, the present invention is a control system integrated inspection platform. When the present invention is inspected, the system is integrated and placed on the right end of the conveyor belt 6. At this time, the second motor 15 drives the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com