Raney nickel catalytic preparation method of 2,2'-bipyridine

A catalytic preparation, Raney nickel technology, applied in the direction of organic chemistry, etc., can solve the problems of staying, unable to achieve large-scale production, low reaction yield, etc., to avoid waste, good economic and social benefits, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

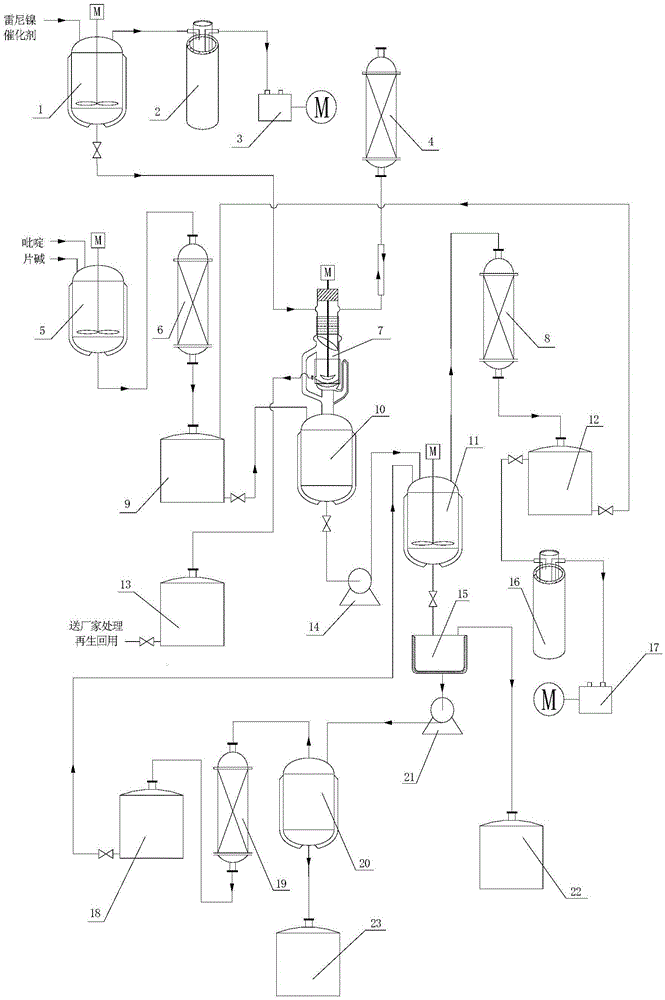

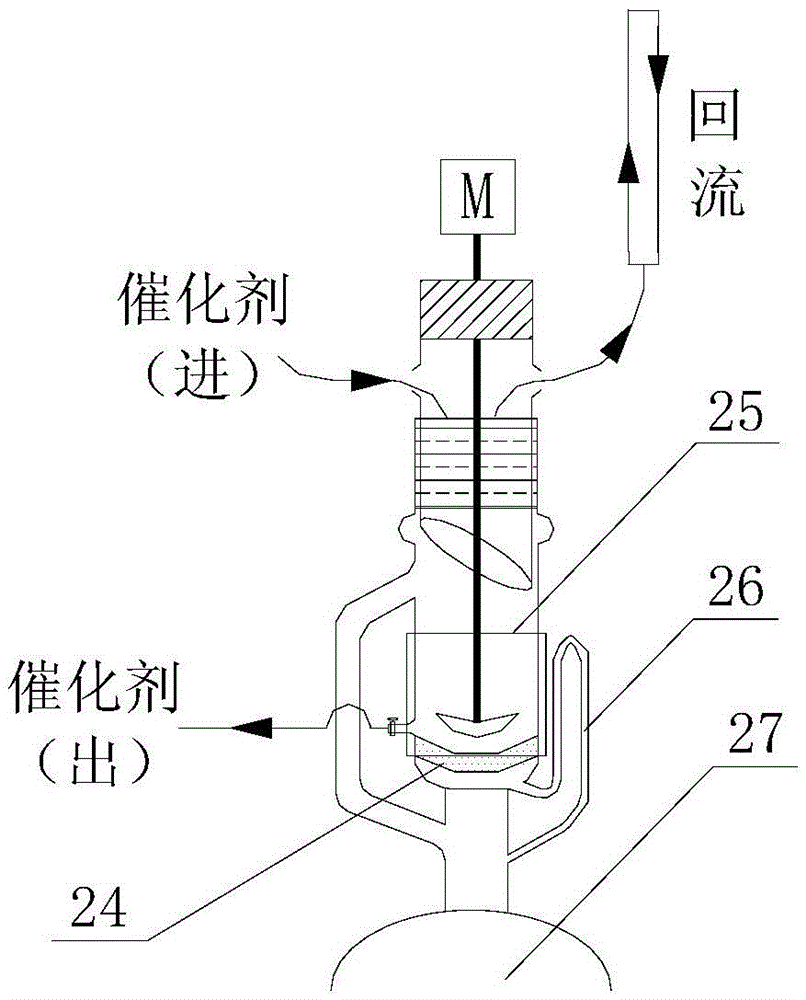

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: first add 1000Kg pyridine into the evaporator, and then add 150Kg activated Raney nickel catalyst into the reactor. Slowly heat the pyridine in the evaporator to 115°C, the pyridine vapor rises to the cooling tower to become liquid droplets and flows back into the reactor, the liquid level in the reactor rises gradually, turn on the stirrer and heating mantle of the reactor, adjust The temperature of the heating mantle is 110-113°C. After the reaction was carried out for 15 hours, add 20Kg of Raney nickel catalyst to the reactor and continue the reaction for 10 hours; then add 15Kg of Raney nickel catalyst to the reactor and continue the reaction for 8 hours to stop. The reaction liquid was distilled under reduced pressure, 800Kg of petroleum ether was added to the distillation residue and the temperature in the kettle was lowered to 45°C, then the petroleum ether mixture was filtered, and the filtrate was distilled to dryness to obtain 627.5Kg of 2,2'-bip...

Embodiment 2

[0020] Example 2: First add 1300Kg of pyridine to the evaporator, and then add 220Kg of activated Raney nickel catalyst into the reactor. Slowly heat the pyridine in the evaporator to 115°C, the pyridine vapor rises to the cooling tower to become liquid droplets and flows back into the reactor, the liquid level in the reactor rises gradually, turn on the stirrer and heating mantle of the reactor, adjust The temperature of the heating mantle is 112-114°C. After the reaction was carried out for 15 hours, 22Kg of Raney nickel catalyst was added to the reactor, and the reaction was continued for 10 hours. Add 20Kg of Raney nickel catalyst to the reactor again, continue to react for 8.5h and stop. The reaction liquid was distilled under reduced pressure, 1000Kg petroleum ether was added to the distillation residue and the temperature in the kettle was lowered to 40°C, then the petroleum ether mixture was filtered, and the filtrate was distilled to dryness to obtain 710.5Kg 2,2'-bi...

Embodiment 3

[0021] Example 3: 1700Kg of pyridine was first added to the evaporator, and 300Kg of activated Raney nickel catalyst was added into the reactor. Slowly heat the pyridine in the evaporator to 115°C, the pyridine vapor rises to the cooling tower to become liquid droplets and flows back into the reactor, the liquid level in the reactor rises gradually, turn on the stirrer and heating mantle of the reactor, adjust The temperature of the heating mantle is 113-114°C. After the reaction was carried out for 15 hours, 32Kg of Raney nickel catalyst was added to the reactor, and the reaction was continued for 10 hours. Add 30Kg of Raney nickel catalyst to the reactor again, continue to react for 8h and stop. The reaction liquid was distilled under reduced pressure, 1500Kg of petroleum ether was added to the distillation residue and the temperature in the kettle was lowered to 43°C, then the petroleum ether mixture was filtered, and the filtrate was distilled to dryness to obtain 1170.4K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com