Microcircuit module back side pre-soldering and pre-soldering heating device

A microcircuit and backside technology, which is applied in printed circuit, printed circuit manufacturing, printed circuit assembly of electrical components, etc., can solve the problems that affect the welding reliability of components, reduce the service life, and the solder is easy to oxidize, so as to ensure reliability and stability, save the amount of solder, reduce the effect of solder oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] The method for pre-tinning the back of the microcircuit module comprises the following steps:

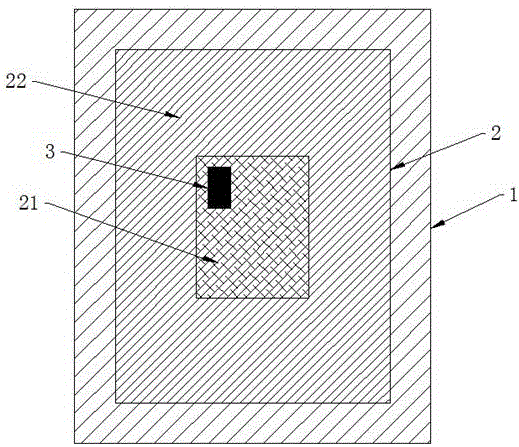

[0029] A. Make tooling 2: Prepare an aluminum-silicon plate, plate gold on the central area of the upper surface of the aluminum-silicon plate, divide the upper surface of the aluminum-silicon plate into a coating area 21 and an uncoated area 22, and make a tooling;

[0030] B. Tooling 2 and workpiece 3 preheating: fix tooling 2 on heating table 1, start heating table 1 to heat the tooling to the preset temperature, place the workpiece to be pre-tinned on heating table 2, and start heating table 2 Preheat the workpiece;

[0031] C. Add solder: place the solder on the gold-plated area 21 of the frock to melt the solder;

[0032] D. Tinning: move the preheated workpiece 3 to the coating area 21 of the tooling 2, the back of the workpiece 3 is in co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com