Coupling catalytic reforming-method and device for film separation reaction

A reaction device and catalytic reforming technology, applied in chemical instruments and methods, hydrogen separation, inorganic chemistry, etc., can solve problems such as methanation, low hydrogen production efficiency, and inability to quickly collect hydrogen, so as to prolong life and avoid side effects Reaction, the effect of improving hydrogen production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

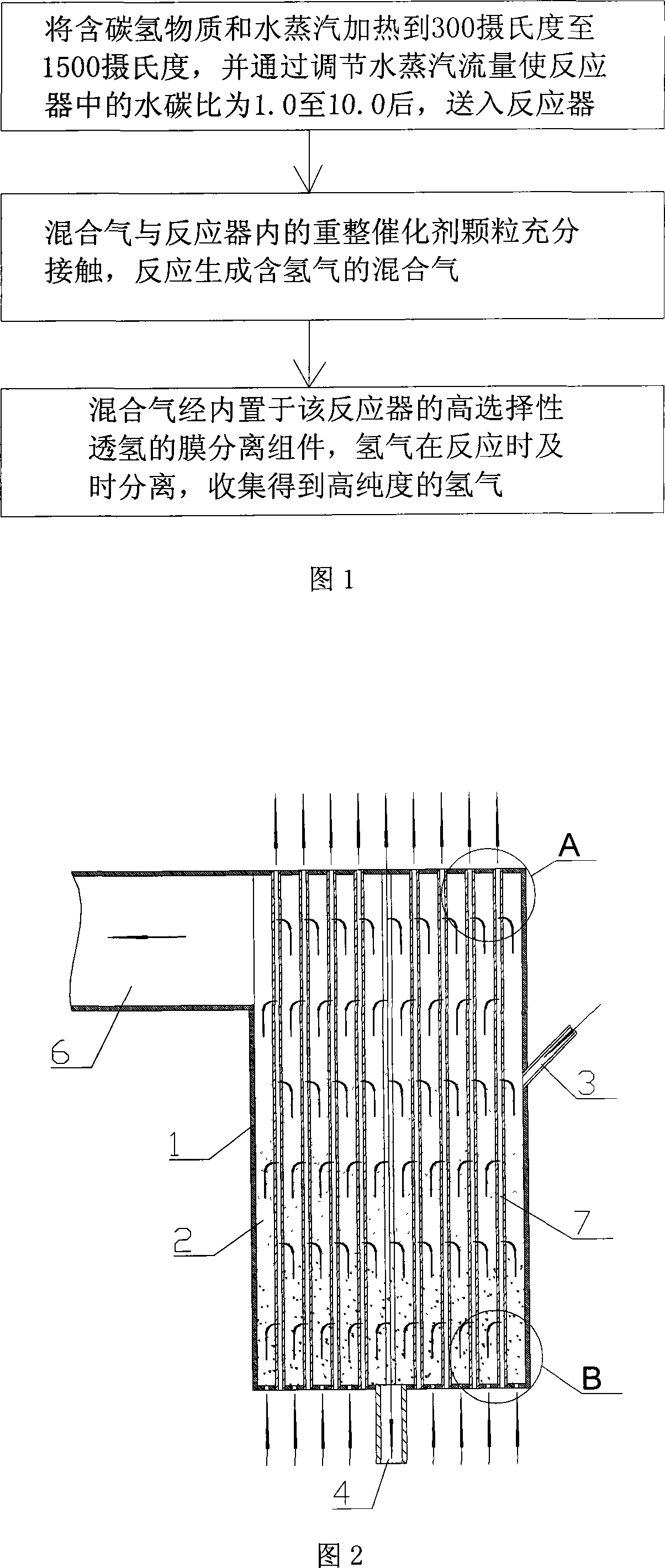

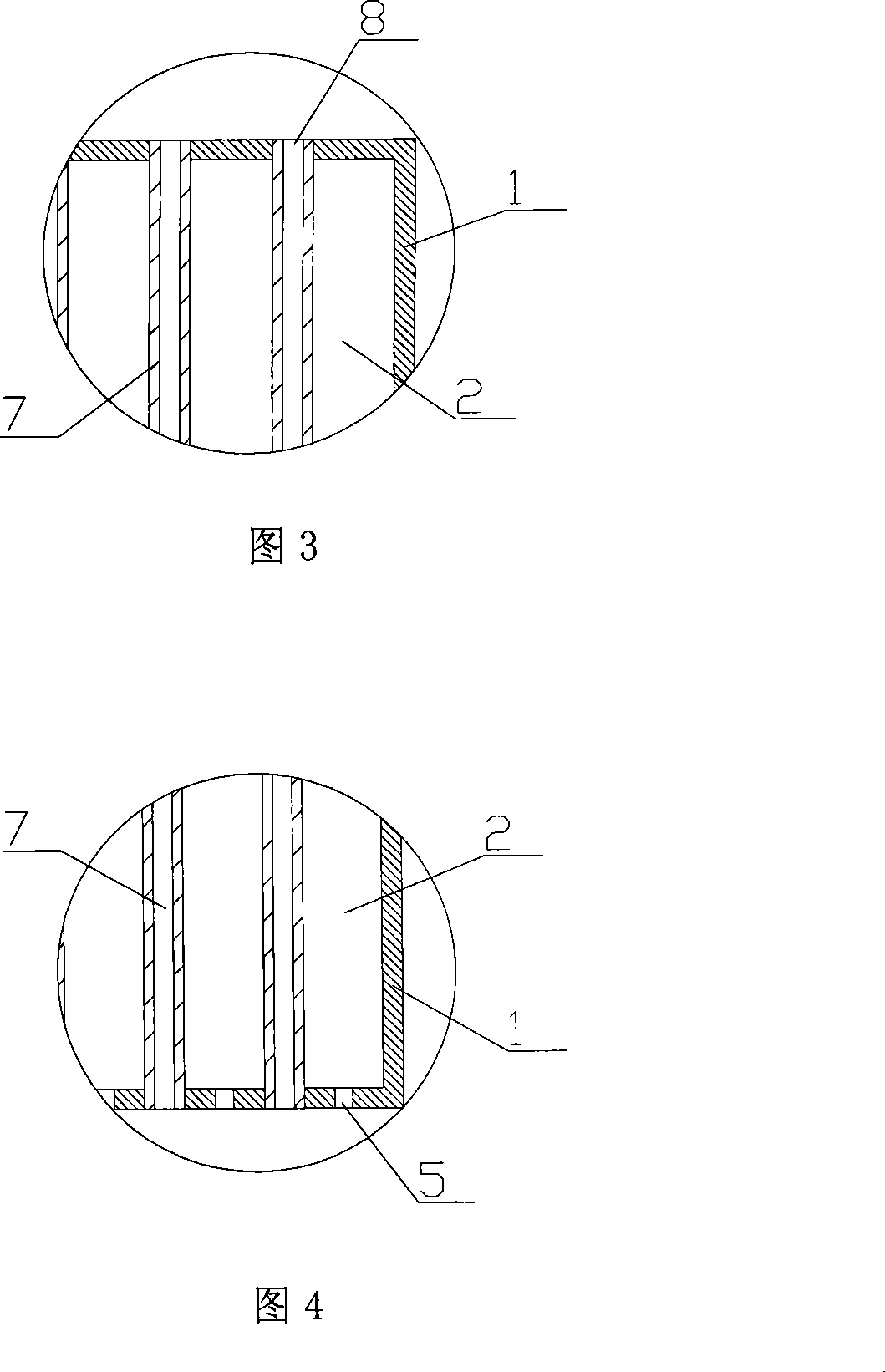

[0021] As shown in Figure 1, a method for coupling catalytic reforming-membrane separation reaction, the method comprises the following steps:

[0022] a. Heating the hydrocarbon-containing substance and water vapor to 400°C to 1200°C, and adjusting the flow of water vapor to make the water-carbon ratio in the reactor 1 be 1.0 to 10.0, and then send it into the reactor 1;

[0023] b. The mixed gas is in full contact with the reforming catalyst particles in the reactor 1 to react to generate a mixed gas containing hydrogen;

[0024] c. The mixed gas passes through the highly selective hydrogen-permeable membrane separation module 7 built in the reactor 1, and the hydrogen gas is separated in time during the reaction, and high-purity hydrogen gas is collected.

[0025] The hydrocarbon-containing substance used in the present invention is one of the following or a mixture of more than one: natural gas, methane, propane, methanol, ethanol, ether, naphtha, coke oven gas, blast furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com